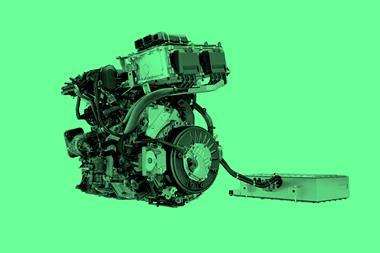

HORSE, a leader in hybrid and combustion powertrain solutions, has started producing its high-performance eMotor at Aveiro, Portugal. Designed for hybrid and plug-in hybrid vehicles, the motor delivers 49kW and 212Nm torque, with a capacity of 160,000 units annually.

Renault-Geely powertrain joint venture, HORSE, (a division of Horse Powertrain) and global leader in hybrid and combustion powertrain technologies, has begun production of its latest innovation: a compact and efficient eMotor. The motor, designed specifically for hybrid and plug-in hybrid vehicles, is being manufactured at the company’s advanced facility in Aveiro, Portugal.

”With its compact design, and the ability to work in 100% electric mode, this powerful and efficient motor is perfect for many types of hybrid vehicle”

- Patrice Haettel, Chief Executive Officer, HORSE

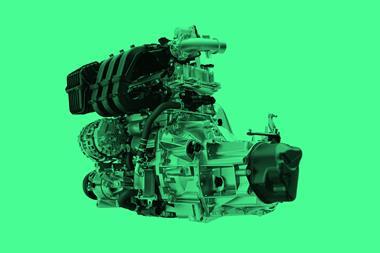

The radial flux eMotor exemplifies HORSE’s commitment to sustainability and innovation in automotive electrification. The motor delivers a maximum power of 49kW and torque of 212Nm, enabling vehicles to reach speeds of up to 130km/h in pure-electric mode. This compact design integrates seamlessly into hybrid powertrain architectures alongside HORSE’s HR12, HR16, and HR18 internal combustion engines.

Patrice Haettel, Chief Executive Officer at HORSE, described the launch as a milestone in the company’s journey toward electrification:

“The start of eMotor production at Aveiro reinforces HORSE’s commitment to delivering efficient powertrains using the latest technology.

“With its compact design, and the ability to work in 100% electric mode, this powerful and efficient motor is perfect for many types of hybrid vehicle. Once again, HORSE has demonstrated its credentials as the ideal partner for our customers on their ongoing electrification journeys.”

”The new lines collectively allow the production of up to 160,000 eMotor units annually”

Cutting-Edge Production Capabilities

To facilitate this advanced production, HORSE’s Aveiro plant has undergone significant upgrades. Four new production lines have been installed, each tailored to a specific phase of eMotor manufacturing. These lines enable the machining of motor housings, rotor shafts, and magnets, culminating in final assembly. Among the technological advancements is a three-head precision winding machine.

The innovative tool ensures faster and more accurate construction of the motor’s core, a critical component in ensuring optimal performance and reliability. The new lines collectively allow the production of up to 160,000 eMotor units annually, underscoring HORSE’s dedication to meeting the growing demand for electrified powertrain components.

![HORSE E-Motor Line [LIMPIO]](https://d2oevnekjqgao9.cloudfront.net/Pictures/480xAny/7/5/0/327750_horseemotorlinelimpio_790314.jpg)

A dual-mode eMotor that shifts between fully-electric and hybrid

The eMotor’s design positions it between the internal combustion engine and the transmission. This configuration enables two distinct driving modes: a fully electric mode and a hybrid mode.

In electric mode, the eMotor drives the vehicle’s wheels directly, offering a zero-emission solution at speeds of up to 130km/h. In hybrid mode, the motor works in concert with the internal combustion engine to provide enhanced acceleration and improved fuel efficiency. Additionally, during deceleration, the eMotor functions as a generator, recovering kinetic energy to recharge the vehicle’s battery.

Read more HORSE stories

- How HORSE is reimagining smart factories in powertrain production

- Oyak Horse hits 7.5 million engine milestone, adds 100 new jobs

- HORSE powertrain continues to expand supply in range extender market

- Q&A with Patrice Haettel: CEO of powertrain tech firm, HORSE

HORSE is positioned for continuous innovation in electrification space

As a division of Horse Powertrain, which operates 17 manufacturing facilities and five research and development centres globally, HORSE leverages decades of expertise in propulsion systems. The Aveiro facility’s latest development is a testament to the company’s ability to adapt to the evolving demands of the automotive sector, offering efficient and sustainable solutions for its partners.

The new eMotor is set to become a key component in the transition to cleaner mobility, aligning with HORSE’s position at the forefront of the automotive electrification movement.

No comments yet