PARTNER CONTENT

This content was produced by Automotive Manufacturing Solutions in partnership with Henkel

ADAS technology demands high-performance computing, generating heat that risks system efficiency and longevity. Henkel’s Bergquist Liqui Form TLF 6500 CGel-SF provides advanced thermal management, reducing stress on components and enhancing sustainability in production.

As advanced driver-assistance systems (ADAS) evolve toward higher levels of autonomy, the demands on vehicle electronics continue to grow. High-performing ADAS components and vehicle computing units such as lidar systems, domain controllers, and infotainment displays, must process vast amounts of real-time sensor data, generating significant heat. Without effective thermal management, these high-performance systems are at risk of reduced reliability, performance degradation, or even failure.

Henkel, a leader in thermal interface materials, has developed Bergquist Liqui Form TLF 6500 CGel-SF to address these challenges, offering superior heat dissipation, reliability, and sustainability in automotive electronics.

”One of the most pressing challenges in ADAS electronics is heat buildup. These systems rely on high-performance processors that generate considerable thermal loads, which, if not managed effectively, can lead to performance slowdowns or even failures”

The increasing need for advanced thermal management in ADAS

ADAS technology is rapidly advancing, integrating sophisticated computing platforms that enable real-time decision-making for autonomous functions. However, the concentration of high-power processors and electronic control units (ECUs) within compact domains intensifies thermal challenges. Without efficient heat dissipation, ADAS components can suffer from increased temperatures, leading to diminished processing efficiency, long-term wear, and potential safety risks.

The Bergquist Liqui Form TLF 6500 CGel-SF provides an effective solution by ensuring optimal thermal management, allowing ADAS domain controllers to operate at peak efficiency without the risk of overheating or long-term degradation.

Solving the thermal challenge in ADAS electronics

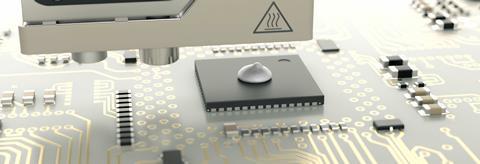

One of the most pressing challenges in ADAS electronics is heat buildup. These systems rely on high-performance processors that generate considerable thermal loads, which, if not managed effectively, can lead to performance slowdowns or even failures. The Bergquist Liqui Form TLF 6500 CGel-SF addresses this issue with a thermal conductivity range of 6.5W/(m∙K), ensuring heat is efficiently drawn away from sensitive components.

By preventing excessive temperature increases, this advanced thermal gel helps maintain consistent processing speeds and extends the overall longevity of ADAS modules, making it a critical component for next-generation automotive electronics.

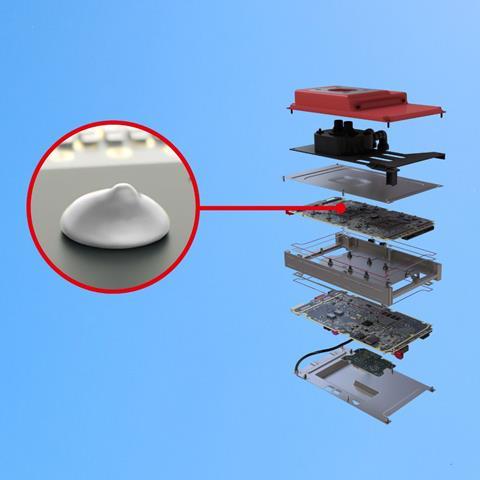

Beyond just dissipating heat, the mechanical integrity of ADAS components is equally important. Traditional thermal management solutions can exert excessive stress on delicate electronic parts, leading to mechanical failures over time. Henkel’s solution overcomes this by offering ultra-low compression stress, reducing mechanical strain on fragile elements.

Additionally, the material effectively fills air gaps and irregular surfaces, ensuring consistent contact and even heat distribution across critical areas. With its elastomeric properties, TLF 6500 CGel-SF remains stable over long operating periods, minimizing risks associated with material degradation and ensuring long-term reliability.

”Henkel has developed the TLF 6500 CGel-SF with low oil-bleeding technology, extending component longevity and reducing electronic waste”

Enhancing automotive manufacturing efficiencies and sustainability

In high-volume automotive production, efficiency and ease of application are key considerations. Many thermal interface materials require complex application methods, leading to increased costs and production slowdowns. Henkel’s Bergquist Liqui Form TLF 6500 CGel-SF resolves this issue with its easy-to-dispense, low-viscosity formulation. This allows for precise application with minimal waste, making it an ideal solution for manufacturers seeking streamlined production processes.

The product requires moisture to be cured, but in room temperature with elevated heat as option, including a standard room-temperature cure for conventional setups and a heat-accelerated cure for faster processing times. Furthermore, unlike traditional thermal gels, this formulation is reworkable, allowing for easier repairs and maintenance in ADAS modules, reducing costly component replacements and downtime.

Sustainability is another critical factor for OEMs, engineers and Tier 1 and 2 suppliers aiming to meet stricter environmental regulations. Many traditional thermal materials contain silicone compounds that can bleed oil over time, leading to contamination and reduced component efficiency. Henkel has developed the TLF 6500 CGel-SF with low oil-bleeding technology, extending component longevity and reducing electronic waste.

Additionally, its silicone-free composition ensures compliance with environmental standards by eliminating D4-D10 compounds, which are increasingly restricted due to their environmental impact. By providing a longer-lasting and more reliable thermal management solution, Henkel contributes to sustainable manufacturing practices while delivering superior performance.

”As ADAS technology continues to evolve, having a robust and reliable thermal interface material is more critical than ever, and Henkel’s latest innovation ensures that automotive manufacturers can meet these challenges with confidence”

Why Henkel’s solution stands out in automotive production

Henkel has built a reputation for engineering cutting-edge thermal management solutions tailored to the demands of modern automotive electronics.

The Bergquist Liqui Form TLF 6500 CGel-SF exemplifies this commitment, offering a solution that enhances heat dissipation while also protecting delicate electronics and improving manufacturing efficiency; aligning with automotive producers’ sustainability goals.

As ADAS technology continues to evolve, having a robust and reliable thermal interface material is more critical than ever, and Henkel’s latest innovation ensures that automotive manufacturers can meet these challenges with confidence.

Contact Henkel’s technical team for expert guidance

Henkel’s team of thermal management specialists is ready to support automotive manufacturers in selecting the right thermal interface material solutions for their applications. To learn more about Bergquist Liqui Form TLF 6500 CGel-SF or to schedule a product trial, contact Henkel’s technical experts at adhesive.automotive@henkel.com

With advanced solutions like Bergquist Liqui Form TLF 6500 CGel-SF, Henkel continues to drive innovation in automotive electronics, ensuring that the future of ADAS remains cool, reliable, and sustainable.

Find out more by contacting Henkel, here

1 Reader's comment