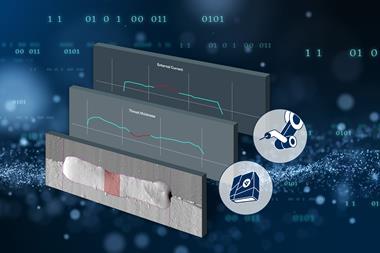

VITRONIC’s vision system inspects each weld in real time with camera sensors using laser triangulation and 3D imaging. It detects even the smallest irregularities, offering engineers accurate insights for fast rework and root cause analysis of the welding process.

- Plant Functions

- Smart Factory

- Register now: Automotive Gateway Mobilizer - Mastering Communication Challenges in Battery and EV Components End-of-Line Tests

- New whitepaper: BASF and Catena-X: Creating a more connected and efficient automotive industry

- Watch now: Digital Transformation at Inflection Point within Automotive Manufacturing

AMS/ABB Automotive Manufacturing Outlook Survey 2024 results

AMS/ABB Automotive Manufacturing Outlook Survey 2024 results

- Electrification

- Automation

- Sustainability

- Events

- Companies

- Materials

- Regions

- Kaizen

- Video and Audio

- Magazine

- Surveys & Reports

- Newsletters

- Partner Content

- Register now: Automotive Gateway Mobilizer - Mastering Communication Challenges in Battery and EV Components End-of-Line Tests

- Watch now: Digital Transformation at Inflection Point within Automotive Manufacturing

Henkel’s advanced thermal management for ADAS reliability

Henkel’s advanced thermal management for ADAS reliability How Henkel is co-developing the EV batteries of the future

How Henkel is co-developing the EV batteries of the future

- Whitepapers

- Media Pack

- Register

- Sign In