The BMW Group has launched a partnership with SK tes to recycle high-voltage batteries across Europe. This closed-loop process reclaims critical materials such as cobalt, nickel, and lithium, boosting sustainability and reducing supply chain risks.

The BMW Group has taken another decisive step in its pursuit of sustainable mobility. By partnering with SK tes, a leader in technology lifecycle solutions, the OEM has reinforced its commitment to the circular economy. The partnership will focus on recycling high-voltage batteries, recovering critical raw materials such as cobalt, nickel, and lithium, and reintegrating them into the value chain. The initiative builds on BMW’s earlier success with a similar closed-loop recycling system launched in China through its BMW Brilliance Automotive Joint Venture in 2022.

BMW is actively driving towards a circular future

On 1 November 2024, BMW launched its pan-European collaboration with SK tes. High-voltage batteries that are no longer fit for use across BMW’s development, production, and European markets will now be delivered to SK tes. The batteries will undergo a recycling process that starts with mechanical shredding, producing a material called black mass. From this, nickel, lithium, and cobalt are recovered through hydrometallurgy, an advanced chemical extraction process.

”BMW plans to expand the initiative to North America by 2026, targeting the US-Mexico-Canada region”

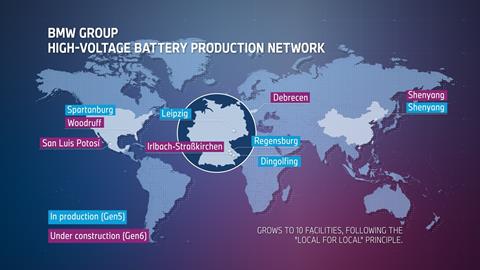

These reclaimed materials will play a crucial role in manufacturing BMW’s next-generation GEN 6 drive trains. BMW’s direct involvement in this process ensures that valuable insights can flow back into its development teams, enhancing future designs and sustainability initiatives.

“Partnerships like this increase our efficiency in terms of the circular economy. In the closed-loop process, all partners mutually benefit from their experiences,” says Jörg Lederbauer, Vice President Circular Economy, Spare Parts Supply High Voltage Battery and Electric Powertrain at BMW AG.

Read More BMW Stories

- How BMW’s San Luis Potosí leads in sustainable production

- BMW partners for innovation in rare earths for vehicle production

- ‘Designing for Circularity’ to lead in sustainability: BMW

- BMW gears up for electric shift with Neue Klasse trials

The closed-loop recycling system is not confined to Europe. BMW plans to expand the initiative to North America by 2026, targeting the US-Mexico-Canada region. This global rollout reflects the company’s broader commitment to sustainable practices in all markets. SK tes’s battery recycling process has already earned international acclaim. It has received accolades such as the Business Intelligence Group’s Sustainability Service of the Year and the UN Global Compact’s Apex Award, highlighting the innovative and environmentally responsible nature of its approach.

A long-term vision for sustainability

BMW’s broader strategy for sustainability aligns closely with the principles of the circular economy. The company adheres to four pillars: Re:Think, Re:Duce, Re:Use, and Re:Cycle. The philosophy underpins efforts from vehicle design and production to recycling and reuse, ensuring that every BMW car, at the end of its life, becomes a resource for future vehicles.

“The promotion of circular economy is an important strategic topic for the BMW Group. The development of recyclable products, the increase of secondary materials in our components, and the closing of loops play an equally important role,” explains Nadine Philipp, Vice President Sustainability Supplier Network at BMW AG.

BMW’s Recycling and Dismantling Centre, which has been operational for over 30 years, exemplifies this approach. The facility has continually refined its recycling processes, enabling the company to make significant strides in reclaiming and reusing parts and materials.

Circular economic principles that are both resilient and responsible

The circular economy is not just about sustainability but also about resilience. By reclaiming secondary materials like cobalt and lithium, BMW reduces its dependency on volatile supply chains and mitigates the risks of raw material shortages.

“And by the means of circular economy we are also increasing our resilience in the supply chains,” Nadine Philipp adds.

This pioneering partnership with SK tes is more than a sustainability milestone. It is a strategic investment in the future, ensuring BMW’s electric vehicles are not only efficient on the road but also part of a broader ecosystem that values resource conservation.

No comments yet