JV a tactical convergence between the OEM with major battery materials player effectively pooling resources and expertise to capitalise on European market as demand booms

Volkswagen group subsidiary PowerCo, and materials technology company Umicore, have announced European battery materials joint venture (JV), Ionway. The new company will focus on large-scale industrial production of cathode active materials (CAM) and their chemical precursors (pCAM), to scale up lithium-ion production for EVs in the EU. Ionway is aiming for an annual production capacity target of 160 GWh by the end of the decade, to provide batteries for 2.2m EVs.

Ionway will serve the dual purpose of supplying PowerCo’s European battery cell factories with crucial battery materials, and securing Umicore’s access to a significant portion of the European demand for EV cathode materials.

‘First-of-its-kind’ collaboration in Europe

The new company is in effect, a convergence of a major OEM and a battery materials producer; highlighting the coalescence of once-disparate aspects of automotive manufacturing and supply chains; boosting the mutual effectiveness of its parent companies.

The collaboration marks the first-of-its-kind alliance, and is driven by a shared commitment from its founding companies to enhance the EU’s presence in the fast-accelerating eMobility industry through the establishment of sustainable, transparent and regional battery supply chains.

CAMs (and pCAMs) as key to global electrification project

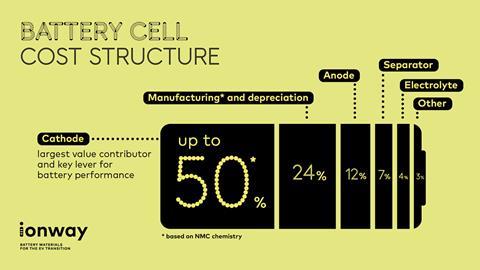

The partnership is the result of the recognition that CAMs are a key element for battery performance.

These materials not only exert the most significant influence on overall battery costs but also play a defining role in determining the carbon footprint of batteries.

As such, they are strategically vital inputs; central to the creation of battery value and essential for a successful transition toward sustainable eMobility in powertrains.

Frank Blome, CEO of PowerCo, commented: “Through Ionway, PowerCo achieves a pivotal milestone in our strategy to vertically integrate the battery supply chain.

”Partnering with Umicore, a trusted ally, allows us to source essential cell production materials at competitive prices.

“This secure access positions PowerCo to deliver cost-competitive battery cells to the Volkswagen Group for years to come, enabling its brands to offer attractive and affordable EVs to customers.”

Mathias Miedreich, CEO of Umicore, said: “Ionway is a start-up with a significant head start, owing to our robust partnership with Volkswagen’s PowerCo and Umicore, key players in the electric mobility transformation. Ionway is poised to become an industry reference in e-mobility, driving innovation, generating hundreds of highly skilled jobs, and facilitating the energy transition.”

Thomas Jansseune, a seasoned leader with 22 years of experience at Umicore - and CEO of Ionway since July 1st 2023, added: “The establishment of Ionway sends a powerful signal for the advancement of battery cell technology in Europe.

“We firmly believe that this company will provide essential building blocks to assist the European Union in achieving its Green Deal ambitions.”

Achim Holzer, the Chief Financial Officer of Ionway, joins from Volkswagen Group Technology, where he served as the Head of Value Engineering & Central Purchasing Functions.

VW’s PowerCo already busy building battery production infrastructure

PowerCo has been busy expanding its footprint, establishing itself as a preeminent player in the battery chemicals infrastructure required for the expanding demand for electrification.

AMS sister publication Automotive Logistics (AL) recently reported on the company’s plans to invest €20 billion by the end of the decade, as it builds a blueprint for battery logistics. An R&D hub dedicated to battery cell technology, complete with a pilot production line, has been actively operating in Salzgitter since 2019, with a battery cell laboratory inaugurated in 2021.

PowerCo has decided on three sites for cell factories: Salzgitter, Germany, Valencia, Spain, and St. Thomas in Canada; breaking into the North American market. The company has already begun construction on its second cell factory in Valencia, with the gigafactory due to start production of the unified cell in 2026. Its North American factory is due to kick off production in 2027.

No comments yet