BYD, one of China’s largest EV makers, has chosen Dürr to equip its first European car plant in Hungary with advanced painting and cleaning technology. This collaboration combines precision engineering with sustainability, showcasing the future of European EV production.

Dürr has announced a significant partnership with Chinese electric vehicle (EV) manufacturer BYD, to equip its first European passenger car factory with advanced painting and cleaning technologies. The partnership marks a significant step for both companies as they expand their influence in Europe’s growing EV market.

BYD’s factory, currently under construction in Szeged, Hungary, and scheduled to begin production in the second half of 2025, will utilise Dürr’s innovative technology to sustainably paint BYD’s EVs. Over the next several months, Dürr has announced it will deploy more than 120 robots, including its EcoRP series for the painting and handling of BYD vehicles, enabling the Chinese OEM’s paint production precision, efficiency and sustainability.

”BYD’s Hungarian facility in Szeged is strategically crucial, with Europe’s investigation into Chinese EV makers casting a spotlight on the competitive dynamics within the EV market”

Dürr and BYD’s partnership set to impact European EV production

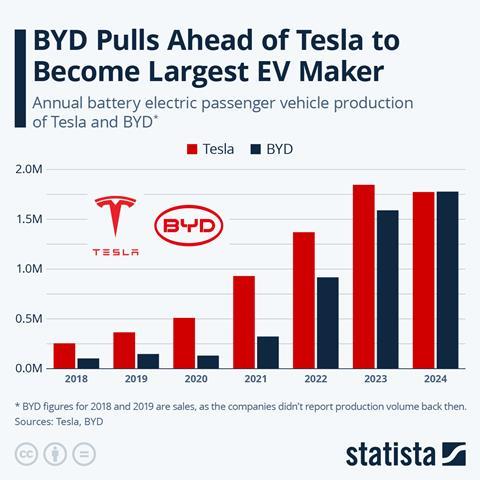

In 2025, BYD, (China’s largest carmakers) surpassed Telsa to become the global leader in EV sales. The Chinese EV maker has strategically chosen Hungary for its European operations. The Szeged facility represents a landmark for the company as one of the first Chinese automakers to establish a car manufacturing plant on the continent.

Dr Lars Friedrich, Head of the Application Technology division at Dürr, highlighted the importance of the partnership: “As a world market leader in automotive painting, Dürr is the right partner to implement projects of this size successfully and on schedule.

“It was not just our outstanding technology that won over BYD, but also our experience in Hungary, where we have already completed a number of projects.”

According to Dürr, the collaboration follows a successful audit of Dürr Systems AG by BYD, highlighting the German firm’s credibility in delivering large-scale projects.

Innovative painting technology to power BYD’s European operations

Dürr’s EcoRP painting robots, featuring six- and seven-axis variants, will be integral to the facility. The seven-axis robot ensures unparalleled precision for interior painting, accessing even the most challenging areas. Meanwhile, six-axis robots will handle exterior painting with equal finesse. These robots will be paired with additional equipment, such as door, lid, and flap openers, to enhance the painting process.

“The [European] Comission proposed tariffs of up to 27% on imported Chinese EVs. The tariffs placed on BYD has been set at 17%; a figure in addition to the 10% import duty that already applies to EVs from China”

The EcoBell3 high-speed rotary atomisers, another highlight of Dürr’s offering, enhances optimal paint application with consistent shade, flow, and layer thickness.

Additionally, Dürr’s modular EcoSupply P paint system, with its innovative pigging technology, reduces paint and solvent waste, contributing to the factory’s sustainability goals. The ‘pigs’ – specially designed components that perfectly fit the diameter of paint hoses – ensure no paint is wasted during application. They push leftover paint back into containers, eliminating residue and negating the need for extensive cleaning.

Sustainability implications of the partnership

Sustainability is a cornerstone of this project. Dürr’s technology will minimise resource consumption and support customisation, enabling BYD to offer special colour options without environmental compromise, according to Dürr.

With EVs now being produced at such a mass scale, the tech aligns with both companies’ broader avowed commitments to reducing their ecological footprint.

The efficiency of the plant is expected to be further enhanced by automated cleaning solutions. Robots equipped with feather rollers will clean vehicle bodies to remove dust and debris before painting. These cleaning systems are flexible enough to handle multiple vehicle designs in various sequences, making them ideal for BYD’s diverse EV lineup.

Dürr’s expertise in robotics and sustainability complements BYD’s ambitious plans to establish a foothold in the European market. This project marks a milestone for Dürr, strengthening its presence in Hungary and is also a major step for BYD which continues to lead the transition towards sustainable mobility.

”Against this backdrop, BYD’s decision to establish a manufacturing plant in Hungary takes on new strategic importance. By building vehicles within the European Union, the Chinese automaker can avoid the proposed tariffs on EV imports”

How BYD is breaking the European stronghold with its Hungary, Szeged facility

BYD’s Hungarian facility in Szeged is strategically crucial, with Europe’s investigation into Chinese EV makers casting a spotlight on the competitive dynamics within the EV market. The inquiry, spearheaded by the European Commission in 2023, was initiated to assess claims of state subsidies provided to Chinese automakers, which are alleged to enable them to undercut European competitors.

The investigation found substantial evidence that Chinese EV manufacturers benefit from significant state support, including grants, tax breaks, and subsidised energy costs, creating an uneven playing field in the global market.

The ramifications of the investigation have been far-reaching for global automotive manufacturing. In response to the findings, the Commission proposed tariffs of up to 27% on imported Chinese EVs. The tariffs placed on BYD has been set at 17%; a figure in addition to the 10% import duty that already applies to EVs from China.

These measures are designed to shield European manufacturers from what the Commission has termed “unfair competition.” However, these tariffs also risk escalating trade tensions with China, which since, warned of potential retaliatory measures targeting European exports.

Is BYD’s Hungary strategy an attempt to circumvent European tariffs?

Against this backdrop, BYD’s decision to establish a manufacturing plant in Hungary takes on new strategic importance. By building vehicles within the European Union, the Chinese automaker can avoid the proposed tariffs on EV imports.

This move allows BYD to maintain competitive pricing for its EVs while aligning with the broader trend of nearshoring in the automotive industry, where companies establish local operations to mitigate geopolitical and logistical risks.

Hungary’s favourable business environment, characterised by competitive labour costs, government incentives, and proximity to key European markets, further enhances the appeal of this location.

For BYD, the Szeged facility represents a dual opportunity: it allows the company to secure a foothold in Europe’s burgeoning EV market while mitigating the impact of regulatory measures targeting Chinese imports.

The broader implications of BYD’s European operations for the automotive industry

BYD’s investment in Hungary signals a potential shift in the competitive landscape of the European EV market. Other Chinese automakers may follow suit, accelerating the localisation of production to bypass trade barriers.

This trend could lead to increased foreign direct investment in Europe’s automotive sector, spurring economic growth but also intensifying competition for domestic manufacturers Moreover, the move underscores the growing importance of technological partnerships in navigating these challenges.

Read More China-Related Production Stories

-

Chinese vehicle makers look to international markets for growth

-

China: Fierce domestic competition sees international brands suffer

Dürr’s role in equipping the Hungary plant with state-of-the-art painting and cleaning technologies exemplifies how collaboration between established European suppliers and Chinese OEMs can drive change, innovation and sustainability in EV production. With Europe tightening its regulatory framework to protect its domestic automotive industry, the strategies adopted by companies like BYD will be critical in shaping the future of the region’s EV market.

With its Hungary facility poised to begin operations this year, BYD is well-positioned to challenge the dominance of established players while contributing to the rapid transformation of European automotive manufacturing.

No comments yet