OEMs are accelerating the transition from ICE to electrification with large investments in start-ups, battery technology, production, upskilling, and smart factories to meet these electric vehicle commitments. But battery technology and chemistry are changing even faster than manufacturers can invest in them, while OEMs, tier-1 suppliers and battery cell producers are all vying to insource key areas of battery manufacturing and add more value, especially as input costs are rising fast.

In this session, hear from technology futurist Greg Ombach and Francisco Carranza from Automotive Cells Company (ACC) – jointly owned by Stellantis, Mercedes-Benz and Total – on how battery technology across the automotive and aerospace sectors will impact on production processes and the value chain. Wath the video and learn more about:

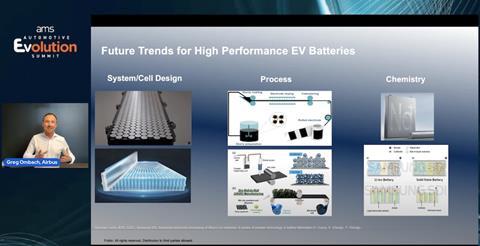

- What changing battery technology, from LFP to sodium to solid state, will mean for battery manufacturing

- Who will be the winners and losers in the manufacturing value chain?

- Opportunities in design for remanufacturing, design for recycling & design for circularity

- What to expect from EV and battery factories of the future

Featuring

Francisco Carranza, Vice President Sales & Marketing, Automotive Cells Company

Grzegorz Ombach, Senior Vice President, Head of Disruptive R&T, Airbus

Download session slides

Hosted by Christopher Ludwig, editor-in-chief, AMS and Ultima Media

Watch more session from the AMS Automotive Evolution Summit on-demand

Sneak preview: the AMS Automotive Evolution Summit is coming in person to Munich! We will host a hybrid event this autumn at the SV Hochhaus in Munich. ZF’s Arno Güllering and BMW’s Dr Peter Weber will be among the keynote speakers at the event.

Interested in participating? Get in touch with our team:

Christopher Ludwig, editor-in-chief

Ahmo Saric, senior content producer

Download session slides

Downloads

Session 5_ ACC_AMS Battery Manufacturing

PDF, Size 1.21 mbsession 5_Greg_Ombach_AES

PDF, Size 1.9 mb

No comments yet