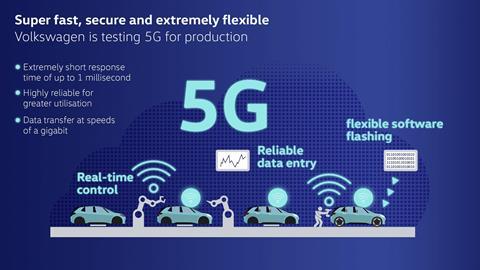

The pilot project will initially cover the main production development centre and the pilot hall, assessing if 5G technology effectively meets the intricate requirements of vehicle production. A dedicated 5G radio frequency will be used to secure data transmissions. VW’s Transparent Factory in Dresden has also put a so-called “5G island” into operation.

The German carmaker is carrying out the setup and operation of the 5G infrastructure in-house in order to develop its competitive expertise in an important technology for the future and ensure its data security.

The pilot project will initially cover the main production development centre and the pilot hall, assessing if 5G technology effectively meets the intricate requirements of vehicle production. A dedicated 5G radio frequency will be used to secure data transmissions. VW’s Transparent Factory in Dresden has also put a so-called “5G island” into operation.

The German carmaker is carrying out the setup and operation of the 5G infrastructure in-house in order to develop its competitive expertise in an important technology for the future and ensure its data security.

“In implementing our Accelerate strategy we are working at full speed to transform our sites into smart factories. Our goal is to continuously optimise our production and make it even more efficient and flexible,” said VW production and logistics chief Christian Vollmer.

He added that 5G technology has “great potential for innovation, from the use of intelligent robots and driverless transportation systems to networked control of plant and machinery in real time up to wireless software flashing of manufactured vehicles.”

The Wolfsburg factory already has around 5,000 robots in operation, as well as various other machines and systems. In order to control and monitor all these complexities, the company believes that a secure, delay-free transmission of data is essential.

Compared to other wireless communication technologies such as WLAN, 5G networks allow for extremely short latency times of up to one millisecond, data transmission rates in the gigabit range, as well as considerable reliability even with high use. This reduction in latency through wireless communication will open the possibility for many smart factory applications to work for the first time.

An example of this, being tested in the pilot phase in Wolfsburg, is the wireless upload of data to manufactured vehicles. With increasingly higher levels of digitisation and fully connected vehicles, the production process requires large data transfers to cars. Once 5G is introduced, it becomes possible to perform this action more quickly and at any point during the production process.

The campus network at the Wolfsburg site will eventually cover large parts of the 6.5 sq. km plant site, according to VW.

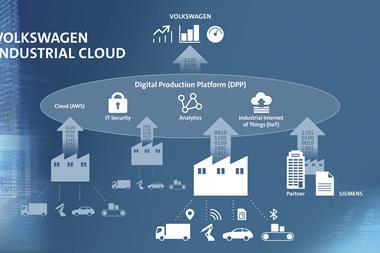

Beate Hofer, CIO of the Volkswagen Group said that efficient wireless communication in real time will be “crucial for flexible production in the future.”

“5G has the potential to be one such driver of the Industrial Internet of Things. Our aim is therefore to build up extensive experience in the operation and industrial use of 5G technology,” he added.

The introduction of better connectivity is a feature that can be seen emerging across the industry. In June last year, Ford and various partners received government support to install 5G connectivity to speed up EV manufacturing.

Vodafone Business delivered the 5G mobile private network at the new E:PriME (Electrified Powertrain in Manufacturing Engineering) facility on Ford’s Dunton Campus.

Likewise, the Bavarian Ministry of Economic Affairs, Regional Development and Energy, the BMW Group and three partner companies from Bavaria began collaboration in May last year on looking at 5G related possibilities for building a logistics smart factory for BMW Group Plant Dingolfing.

The 5G wireless technology trial network is intended to play a key role in linking different logistics solutions.

No comments yet