The use of laser welding of automotive powertrain components is gaining momentum. Its advantages are weight, space and material savings compared to traditional assembly techniques. Due to its low-heat input attribute, laser welding provides nearly distortion-free welding at a high speed compared to other welding technologies.

This webinar gave an overview of a number of processes and production solutions to overcome existing challenges, along with guidelines defining realistic limits for these parameters.

This webinar was presented by:

After receiving his degree in 2011 Matthias joined the laser process development group for powertrain applications at Daimler in Stuttgart, where he took care of prototype development as well as new laser processes in production. At the same time he became an international welding engineer. He joined TRUMPF in August 2014 as a member of the Industry Management Automotive as technology expert for laser applications in powertrain worldwide.

About TRUMPF

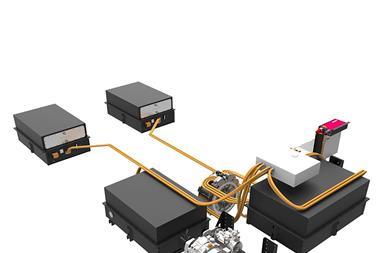

The TRUMPF Group ranks among the leading manufacturing companies worldwide. In the field of industrial lasers and laser systems, the company is the global technological leader. With 60 subsidiaries and branch offices, the Group is represented in almost every European country, North and South America as well as in Asia. As the world’s leading provider of laser manufacturing technology, TRUMPF is the one-stop shop for all auto manufacturers and suppliers seeking cost-efficient, high-speed, top-quality solutions for their production requirements: starting with laser systems and extending through beam sources, beam guidance, optics and numerical control, to all inclusive service and support.