Siemens discusses how the latest digital tools are enabling the transition to e-mobility and explains why these are now essential to OEMs and tier suppliers if they are to create transparent, sustainable supply chains

Autonomous vehicles, electrification and shared mobility are the key trends influencing the strategy and investments for most automotive manufacturers and suppliers today. These trends, along with increased competition, are causing automakers to rethink their business models and prepare themselves for fundamental changes in their design, manufacturing, supply chain and aftermarket processes.

Embracing digitalisation to survive the present and win the future

The automotive industry has been on a digital transformation journey over the last few decades. Advances in computing power, internet connectivity and speed, and next-generation technologies have accelerated this transformation to a new level. More recently, companies who embraced digital transformation were able to manage their business operations and supply chains more effectively amid disruption. For others, it was a key learning to accelerate their digital transformation or run the risk of being left far behind their competition. Digitalisation, a comprehensive digital twin and the digital thread have become a necessity to support the rapid pace of innovation and complexity in today’s market.

At Siemens, we believe that the true leaders in industry will harness complexity as a competitive advantage. Our strategy to provide a competitive advantage for our customers is based on the Siemens Xcelerator portfolio, the comprehensive and integrated portfolio of software, hardware and services that enhances electronic and mechanical design, system simulation, manufacturing, operations, logistics and lifecycle analytics. Now companies of all sizes can access the digital technologies necessary to transform the way they compete, collaborate and connect.

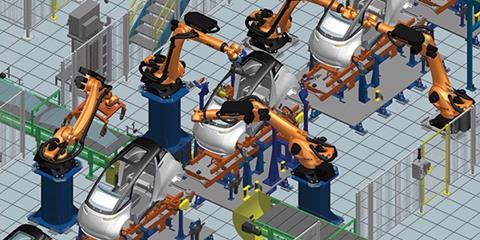

Smart manufacturing and electric vehicle production

With a comprehensive digital twin, automotive companies can attain highly efficient production by leveraging advancements in product, production and supply chain technologies. Siemens digital manufacturing solutions support the engineering and validation of the processes and equipment required for the assembly of new products, the definition of a modern virtual factory to produce these products and the use of information from the connected, real world to accelerate and improve production and supply chain execution.

Product advancements

One of the more challenging aspects of electric vehicles is overcoming consumer range anxiety. As battery technology improves, helping to reduce the size and weight of battery pack assemblies, manufacturers continue to focus on reducing the overall weight of the vehicle. New materials are being utilised for body and chassis components, which has implications for manufacturing. For example, to join these materials together new or advanced technologies involving rivets and adhesives, and production techniques from other industries may be required.

Another example is additive manufacturing, which has its own set of requirements like specialised equipment not readily found on traditional manufacturing shop floors. And the carbon footprint of supply chains to support these product advancements must be considered during product design and early manufacturing planning using sustainability related insights for external cost and emissions calculations and rate card management.

The introduction of new materials integrated with traditional steel parts or components produced with additive manufacturing may drive the need for specialised joining processes like laser welding. These processes require precise programming to meet quality and structural requirements that may not be possible with traditional methods. Programming in the virtual world with the digital twin enhances speed and accuracy of the activity. Programs are validated and optimised before being sent directly to production equipment on the shop floor using offline programming.

To reduce risks, many will start in prototyping. But to get these new products to market in a timely manner they must find a way to accelerate the transition from prototyping to large-scale production using these technologies to meet volume requirements.

Factory evolution

New technologies and consumer demands are driving changes in how vehicles are produced. The factory of the future must enhance production by making improvements in three main dimensions. First, factory infrastructure will contain a multidirectional layout supported by driverless transportation systems, modular line setups that can be reconfigured to support changes in demand and sustainable production that makes efficient use of energy and materials. Second, factory digitalisation will increase. Smart robots that can adapt to changing conditions will be deployed to support flexible production scenarios and collaborative robots (cobots) will be deployed to work alongside humans to ease manual operations. Digital tools like augmented reality, virtual reality and simulation will become commonplace to support these complex systems. Third, factory processes themselves will change, becoming more customer-centric to enable a higher degree of personalisation.

Manufacturing engineers must decide on the level of automation required for assembly processes. Available floor space, costs, process conditions and labour availability are just a few of the factors to be considered. The digital twin can be utilised to evaluate worker posture, vision and accessibility. Specialised equipment or aids can be identified and added to ensure a safe and comfortable working environment and to avoid undesirable designs that may result in quality issues.

Robotics can support flexible processes for complex assembly in a very repeatable fashion. Programming must be orchestrated properly with other aspects of workcell control like synchronisation and safety. Process simulation can be used to digitally engineer and validate robotic applications. Using Process Simulate in the Tecnomatix portfolio, engineers can select and place robots properly in a workcell so that they fulfil all the required tasks. Potential interference conditions or safety concerns can be identified and solved prior to physical installation and programming and interlocks with other automation can be fully defined and validated prior to launch.

It is no longer required to completely guard a robot cell from people. Cobots can co-exist within a workcell alongside their human counterparts. These robots can directly assist operators to facilitate assembly or improve ergonomics. The digital twin can be leveraged to prove out a process, address safety concerns and train operators.

Nothing beats a first-hand impression. We have moved far beyond the cardboard and wood mock-ups of long ago with 3D layouts and digital twins, but we still have a need for a first-person perspective. This is where virtual reality (VR) fits in. With VR, engineers can be completely immersed into the 3D scene where they can interact with the simulation and its components. Issues are more easily identified and captured for further analysis and resolution. Collaboration is enhanced dramatically as multiple participants can join from different physical locations and conduct virtual reviews.

To support a modular and flexible factory architecture, we must de-couple the logistics from the physical line. Driverless transport systems or AGVs will communicate directly with production equipment to move material or production jobs between assembly locations. Debugging or testing these systems directly on the production floor increases risk and may cause delays. By connecting the digital twin of manufacturing directly to virtual models of the production centres and the fleet manager, production scenarios like traffic control, obstacle avoidance, automation interlocks and others can be tested and validated prior to execution on the production floor.

Many manufacturers will be faced with the challenge of mixed-model production as they transition their existing portfolios to support production of electric vehicles. Common assembly lines may be utilised to produce different types of products. Production personnel must create a balanced plan to meet production targets. This plan must account for cycle time, material and logistics, as well as station capabilities and equipment. Planners must account for all required operations to build a specific product variant. Easy-to-use, web-based planning solutions support this activity. Using Easy Plan, planning engineers are presented with simultaneous visibility to station content, required operations for each product variant and assignment status. Operations can be allocated to specific stations with immediate feedback of the impact on cycle time and assignment status, ensuring process completeness.

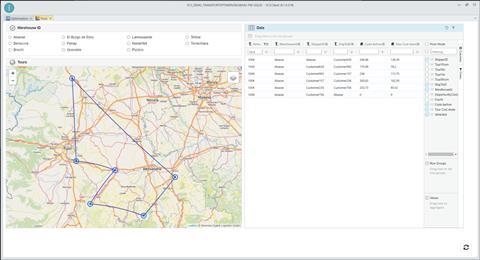

It is not enough to just consider individual production workcells. To fully understand and optimise production we must consider the entire system behaviour. By leveraging factory simulation, engineers can perform multiple experiments very quickly to gain confidence that their plan and design will meet production requirements. Using Plant Simulation in the Tecnomatix portfolio, models can be developed with varying degrees of detail based on data collected directly from the shop floor.

These models help to answer critical questions at any phase of the engineering lifecycle and are often utilised to evaluate and fine tune system architecture, material flow and logistics, and energy usage. Using Supply Chain Suite, these insights can be extended deep into the critical logistics space, including warehousing and transportation, to create a true end to end digital twin.

Production excellence

Digitalisation does not end during the engineering phases of product or factory development. To fully leverage the value of a digital twin we need solutions that can connect to real production and supply chain networks and provide meaningful information back to any point of the connected digital thread.

Integration with PLM, ERP and logistics systems enables our customers to transform virtual production and production orders into real production execution and product delivery. Our solution collects the bill-of-material and bill-of-process from PLM and the production orders from ERP. This information is compared with real-time information from the shop floor, like machine availability and maintenance status, to generate an optimised production schedule. Logistics can then be synchronised and supported by AGVs inside and further enhanced with connections to supply chain systems outside of the factory walls.

Our connected hardware and software solutions can collect raw data directly from the shop floor. This data can be enriched with detailed information resident in the PLM system providing the necessary context to transform raw data into actionable information. This information can then be distributed at the correct time and to the correct department. This collaborative, closed-loop manufacturing approach helps our customers synchronise and optimise across product design, manufacturing engineering, production planning, manufacturing execution and logistics to improve cost, time and quality, and accelerate the delivery of products to the market.

Closely coupled with closed-loop manufacturing (CLM) is closed-loop quality (CLQ). While CLM is primarily focused on improving production of the current product, CLQ is focused on improving the quality of the product across its entire lifecycle. CLQ is a continuous process, evaluating product quality at each stage and feeding quality information back into production and design processes. Its purpose is to ensure the quality of the current product while helping to improve the quality of next-generation products. Quality engineers can use Opcenter Quality and Teamcenter Quality solutions for this purpose.

The time is now

Electric vehicle manufacturing presents new and novel challenges to automotive OEMs and start-ups seeking to become major electric mobility players. These companies must adopt advanced manufacturing technologies, develop modular production facilities and operate resilient supply chains to produce the lightweight and flexible platforms needed for next generation EVs.

Integrated and digitalised manufacturing planning, simulation, execution and logistics solutions can help vehicle manufacturers adapt and overcome these challenges by uniting manufacturing with design and the real world with the digital world. This will enable them to accelerate production planning and ramp-up by virtually designing and validating production processes for cycle time, product quality and operator ergonomics. Integrations with product design solutions allow engineers to optimise product designs for manufacturing and leverage the product digital twin during manufacturing planning and simulation. Robust PLM solutions ensure that an unbroken digital thread is maintained among OEMs and suppliers throughout the product and supply chain lifecycle.

Consumer preference is shifting towards e-mobility as costs continue to drop, bolstered by government regulations and increased accessibility. As the competition increases, companies that embrace digitalisation from product definition and manufacturing to production and supply chain will be able to deliver higher quality products to market in less time and respond to changes with greater agility and intelligence. This capability will be necessary to succeed and thrive in the age of electrified mobility.

The time is now to move electric vehicle production into the fast lane. Siemens is the right partner to help you start your digital transformation today.

Find out more here