At its historic Berlin-Marienfelde plant, Mercedes-Benz is building a new model of connected manufacturing. Through MO360, AI and cloud integration, it is turning data into action across a globally standardised production network

In a factory once best known for mechanical innovation, Mercedes-Benz is now testing the very boundaries of digital production. At its Digital Factory Campus in Berlin-Marienfelde, the carmaker is redefining the principles of connected manufacturing. Drawing from the legacy of more than 120 years of production, the company is pivoting from conventional automation to a new paradigm where artificial intelligence, cloud-based ecosystems, and human-machine interactions form a connected, intelligent production network.

On a visit to its Digital Factory Campus, AMS found out just how. “This site is one of the most historic within our production network, operating since 1902,” said Joerg Burzer, Member of the Board of Management for Production, Quality & Supply Chain Management. “This legacy is deeply connected to the concept of quality and the ‘Made in Germany’ reputation. For us, craftsmanship is not a relic of the past. We believe that combining high-end skills with digitalisation is the key to efficient, high-quality production.”

”Because such systems hinge on data, Mercedes-Benz is extending that connectivity into how it manages and analyses production information”

Digitalisation and AI catalyse connected production through MO360 at Berlin-Marienfelde

Burzer outlined how Mercedes-Benz is taking this idea forward by investing heavily in digitalisation and AI. The Berlin site has become the global epicentre of MO360 - short for Mercedes-Benz Operations 360 - a digital production ecosystem that now spans more than 30 manufacturing plants worldwide. Built to standardise data, workflows and analytics across the network, MO360 brings transparency to every corner of the factory floor.

Wolf Poppe, Head of Digital Plant MO360 Planning & Control, described it as “a digital ecosystem, like what you have on your smartphone or laptop: multiple interconnected applications, sharing a consistent look, feel and standards, designed for ease of use.”

With ten core applications already deployed across quality management, logistics, and maintenance, MO360 is not merely a monitoring tool, but a connected digital nervous system for production. The result is a more responsive factory capable of adapting to changing conditions and model variations.

“Our first application was the digital assistant for shopfloor management. Since then, we’ve grown to ten applications covering a wide range of tasks, including quality management, logistics and maintenance. All of them are developed, tested, and deployed from the Digital Factory Campus. Over the past year, we’ve completed over 200 rollouts. Today, more than 30,000 users engage daily with MO360 applications across our global network.”

- Wolf Poppe, Head of Digital Plant MO360 Planning & Control, Mercedes-Benz

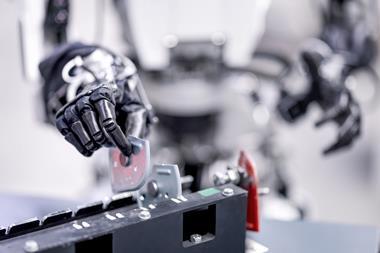

Connecting human-machine interaction in vehicle manufacturing

Connected manufacturing is also reshaping human-machine interaction. Connected digital ecosystems are now finding themselves including simple shopfloor tools as nodes in the system. In a live demonstration, Screw Technology Specialist Maike Holtz demonstrated how, as part of Mercedes-Benz’ MO360 ecosystem, smart tightening tools automatically adjust torque settings using real-time positioning data and upload the results to the cloud for traceability.

She said the smart tightening tool is “connected in real-time to our production line and linked to the digital worker assistant. When a colleague steps into the vehicle, the system uses positioning data to sync the tool with the vehicle. It automatically adjusts the torque and angle settings for the screw that needs to be tightened.

“Pay attention to the LED ring on the tool,” she told the workshop group that I was a part of. “Once the tightening is complete, a green light confirms a successful operation. Simultaneously, the result is transmitted to the cloud, enabling full traceability and real-time quality control.”

In other words, even the information transmitted from the use of these simple (yet crucial) shopfloor tightening tools is fed back into the OEM’s vast data cloud for the use and improvement of the OEM’s entire production network. That which is ‘learnt’ in Germany, is automatically ‘taught’ in the US.

“This is how we are entering a new era of digital craftsmanship”

- Stephanie Knizkov, Head of the MO360 AI Factory

“MO360 is standardised across Mercedes-Benz’ entire global production network,” confirmed Holtz. “This means our colleagues in China, Hungary, the US, or Germany all operate under the same digital processes. This standardisation also extends to training and qualifications. Beyond production, MO360 also supports maintenance, logistics and quality control - creating vast amounts of data.”

Democratising data via cloud and AI for shopfloor and wider production optimisations

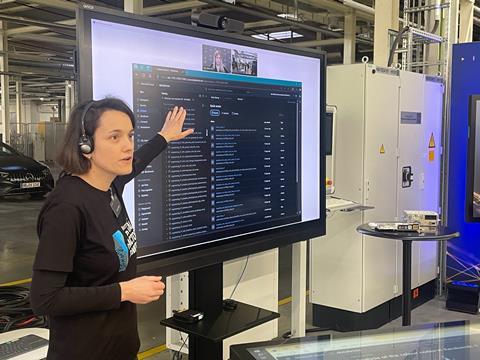

And because such systems hinge on data, Mercedes-Benz is extending that connectivity into how it manages and analyses production information. Chantal Schöpke, Product Owner for the MO360 Self-Service Platform, presented a vision of “data democratisation,” where even non-technical staff are able to interact with data via natural language AI assistants, through a ‘self-service feature’.

“With Databricks Genie, (Databricks’ AI feature) employees can ask production-related questions in plain language, and receive structured, visualised answers instantly” she explained - and all this without the need for any data-analysis or fundamental technical understanding.

Read more Smart Factory stories

- Mercedes-Benz advances AI and robotics in production

- Digital transformation at inflection point within automotive manufacturing

- The urgency for enhanced Design For Manufacture (DFM) in vehicle production

- Smart factories and partners power JLR’s circular seat foam

Schöpke walked through using Databricks, showing how employees can access the unity catalogue, to obtain any data relating to quality, shopfloor, engineering, or supply chain, just to name a few. To show how the system worked, Schöpke proceeded to connect with a colleague at the carmaker’s plant in Kecskemét, Hungary, and working together, they troubleshooted a vehicle paint-related problem in real-time. The carmaker’s employees are able to ask questions in natural language, direct the system to generate data tables and visualisations, and even generate and copy SQL code for further analysis, if needed.

Unifying vehicle and production data through Mercedes-Benz Operating System (MB.OS) and AI agents

The underpinning of MO360 is its integration with the Mercedes-Benz Operating System (MB.OS), a software infrastructure that unifies vehicle and production data. Patrick Niedzwetzki, MB.OS specialist, described how this architecture enables a tenfold improvement in software delivery speed while managing triple the data volumes. It also ensures that vehicles receive the latest software updates directly on the assembly line - a milestone in aligning product development with factory operations.

But it is artificial intelligence that increasingly binds this network together. “AI is not just a trend. It is already embedded in our production lines,” said CIO Katrin Lehmann. “We developed these solutions not in isolated office labs, but together with our frontline colleagues.”

She pointed to examples like ML360AI, a chatbot system that provides instant production support, and the MO360AI multi-agent system, which replicates the dynamics of a cross-functional task force using collaborative AI. As Nicolai Gruber, Senior Consultant AI & Ideation, explained, the system allows agents specialised in quality and assembly, coding and logistics to work together in a virtual environment, tracing root causes and proposing actions within minutes.

”Yes, we believe these AI-generated answers can be trusted - because they are transparent, observable, and always linked to source data”

- Nicolai Gruber, Senior Consultant AI & Ideation

Each recommendation is accompanied by source documentation and accessible in multiple languages, ensuring transparency and trust. “Yes, we believe these AI-generated answers can be trusted - because they are transparent, observable, and always linked to source data,” Gruber said. For Lehmann, such tools liberate engineers to focus on meaningful work. “Engineers don’t want to waste time on tedious documentation. We are giving them tools to do what they love: solve meaningful problems.”

The new era of digital craftsmanship: accelerating ideation and execution through AI

The carmaker is also capturing tacit knowledge from shopfloor staff. Stephanie Knizkov, Head of the MO360 AI Factory, described an ideation process designed to turn frontline ideas into AI use cases. “AI is not something we build in isolation - it is created with our colleagues, from the initial idea through to deployment,” she said. “This is how we are entering a new era of digital craftsmanship.”

The Digital Factory Campus in Berlin is more than a pilot site. It is a connected, digital proving ground, integrating digitalisation, smart factory principles, AI, and large data networks into a unified system. The impact is not limited to Berlin. With MO360 standardised globally, innovations are rapidly deployed across Mercedes-Benz’s production network, enhancing flexibility and responsiveness.

If Mercedes-Benz is to meet the demands of EV acceleration, software-defined vehicles, sustainability goals, and volatile supply chains, connected manufacturing must be more than a vision. In Berlin, it is already a reality.

No comments yet