BMW’s dingolfing plant pioneers automated in-plant driving, achieving CE certification and setting a benchmark for efficiency in automotive production. Expansion across its global network is underway.

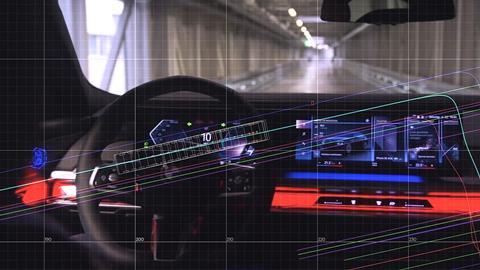

BMW is harnessing cutting-edge automation to revamp how its vehicles are built. At the heart of this transformation is Automated Driving In-Plant (AFW), an innovation that aligns with the automaker’s ambitious BMW iFACTORY framework. This initiative, launched in 2022, has now advanced from pilot testing to series operations at the company’s flagship Dingolfing facility in Germany, following CE certification. The implications for efficiency and in automotive production and logistics are far-reaching.

Dingolfing has become a proving ground for the future of production. The plant employs autonomous vehicles to navigate an intricate 1km route that spans two assembly halls, a short test course, and finishing area. “Automated Driving In-Plant optimises our production process and delivers significant efficiency gains for our logistics,” states Milan Nedeljković, Member of the Board of Management of BMW AG responsible for Production.

Read more BMW stories

- BMW pivots to hydrogen logistics for sustainable production

- Regensburg plant wins flexibility, digital production award

- BMW: ‘Designing for Circularity’ to lead in sustainability

- Debrecen Paintshop hits fossil-free milestone

The operation relies on a sophisticated ecosystem of sensors and cloud technology. Europe’s largest LIDAR infrastructure underpins this system, coupled with an external movement planner and environment model. Remarkably, this set-up functions independently of a vehicle’s built-in equipment.

Embotech AG, a Swiss start-up nurtured by BMW’s START-UP Garage, has contributed key components, reflecting BMW’s ongoing collaboration with innovative technology firms.

“The facility, already producing the MINI Countryman alongside other BMW models, aims to integrate automated driving for 90 percent of its output”

BMW scaling innovation across its production network

Following its success in Dingolfing, BMW is set to implement AFW at its Leipzig plant. The facility, already producing the MINI Countryman alongside other BMW models, aims to integrate automated driving for 90 percent of its output. Leipzig is only the beginning; plants in Regensburg and Oxford are slated to follow in 2025, while the upcoming site in Debrecen, Hungary, will incorporate the technology from its launch.

The applications extend well beyond the factory floor. BMW envisions the technology navigating testing zones and outdoor distribution areas. The synergy between production and development teams is vital to refining the system. A significant focus is the gradual incorporation of on-board technology to complement external sensors, further enhancing operational flexibility.

“Over the next ten years, we will log several million test kilometres with Automated Driving In-Plant in our production network alone.”

- Milan Nedeljković, Member of the Board of Management responsible for Production, BMW

A benchmark for manufacturing and beyond

Nedeljković underscores the long-term vision, stating: “Over the next ten years, we will log several million test kilometres with Automated Driving In-Plant in our production network alone. In this way, the BMW Group is once again setting a new benchmark for automation and digitalisation of its production processes – while paving the way for future applications in the field of autonomous driving.” BMW’s move pushes the OEM to further position itself at the forefront of automotive production innovation, setting a standard that competitors should learn from.

No comments yet