This year's issue of Automotive Paintshop Solutions is now available to view for free here, covering the latest developments by paint suppliers, current paintshop projects by vehicle-makers, trends in robotics, the most advanced quality-control technologies and software to improve energy efficiency.

This year's issue of Automotive Paintshop Solutions is now available to view for free here, covering the latest developments by paint suppliers, current paintshop projects by vehicle-makers, trends in robotics, the most advanced quality-control technologies and software to improve energy efficiency.

The in-depth articles are as follows:

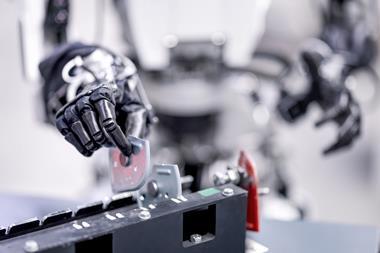

Keeping finishes up to scratch – As vehicle-makers add more innovative materials in body construction and change their production processes to meet new environmental regulations, paint suppliers are striving to meet their needsInterview: Klemens Bartmann, Axalta – As the coatings company turns 150 years old, its global technology director reflects on the sector’s trends, challenges and opportunitiesAchieving Acura-cy – As production of the 2017 Acura NSX ramps up at the dedicated Performance Manufacturing Center in Ohio, AMS investigates what technologies and processes are required to create a finish fit for a supercarPrimed for premium – As Audi prepares to become the first OEM to export high-end vehicles made in Mexico, we look at the new paintshop in PueblaPacifica progress – As FCA US smoothly implements a $744m upgrade at its Windsor plant in Canada, AMS focuses on the new equipment in the paintshop, including innovative oil separation technology and a robotic sealing systemThe interior view – Exterior finishes may catch the eye, but interior coatings also fulfil aesthetic and functional needsTaking a shine to plastics – As tighter legislation restricts the use of traditional electroplating materials, a new method of plastics metallisation developed by Oerlikon Balzers could provide an alternative with wide-ranging benefitsSeeing the light – With the attractiveness of a vehicle’s finish remaining key to purchasing decisions, automotive manufacturers are striving for better means of quality control. AMS reports on the latest technologiesPower to the machines – While human flexibility offers advantages in the assembly hall, modern paintshops rely heavily on automation to tackle hostile conditions and a strong need for consistency. AMS reviews the recent trendsMonitoring vital statistics – As OEMs look to reduce energy use in their paintshops, the latest software can improve efficiencyMixing together – At the latest coatings show, held in Karlsruhe, Germany, companies from a range of industries converged to share ideas and innovations. AMS went to see what might be of interest to automotive players.

Contributions from key suppliers include:

Brilliant simplicity – Geico Taikisha’s Daryush Arabnia explains how the company's new LeanDip system was inspired by customer feedbackChoices for China – BAIC ZengCheng's new plant is a typical example of perfect collaboration between a customer's requirements and ABB's expertiseSpecial colour spectrum – BASF's Coatings’ laboratory manager Michael Brünnemann and product manager Stefan Sickert describe how the company is responding to the special colour needs of OEMsMultistory makeover – An international team made its way to China as Dürr completed a major modernisation project in record timeThe call of customising – With the popularity of personalisation, OEMs are looking to their painting lines and partners such as Kremlin Rexson Sames to provide the answersSkid-free flexibility – Eisenmann describes how, with the energy savings it brings, its skidless paintshop is proving to be a popular idea.Less noise, less cost, more benefits – When Iveco decided to renew its paint circulation line pumps in Madrid, Graco stepped forward with a more efficient and quieter solutionBrake cover – UV coating technology offers perfect protection for discs and the environment, Sprimag says.