At its Berlin-Marienfelde site, Mercedes-Benz is integrating artificial intelligence and humanoid robotics into automotive production. With new digital tools and axial-flux motor technology, the factory is setting new global standards for intelligent manufacturing.

Mercedes-Benz is supercharging its production ecosystem, reinforcing Berlin-Marienfelde’s role as a global hub for innovation. The automaker is integrating artificial intelligence (AI), humanoid robots, and pioneering digital manufacturing processes, setting new standards for intelligent automotive production. These developments are centred at the Mercedes-Benz Digital Factory Campus (MBDFC), where the latest production technologies are tested and deployed across the company’s global network.

“Artificial Intelligence and humanoid robots open up an exciting new frontier which makes automotive production more sustainable, efficient and more intelligent”

- Jörg Burzer, Member of the Management Board, Mercedes-Benz Group AG, Production, Quality & Supply Chain Management

What is the new heart of digital transformation at Mercedes-Benz?

The MBDFC, established in 2022, has become the company’s central competence centre for digitalisation, integrating AI-powered tools into its Mercedes-Benz Cars Operations 360 (MO360) production ecosystem.

MO360 serves as the digital backbone of the company’s global manufacturing operations, enabling seamless software integration and data-driven decision-making. Enhancements to MO360 now include AI-powered tools such as the Digital Factory Chatbot Ecosystem and the MO360LLM Suite.

These features improve data accessibility, streamline manufacturing processes, and enhance overall production efficiency. New software applications are trialled at Berlin-Marienfelde before being implemented in assembly plants worldwide. The site recently played a key role in preparing the Rastatt plant for the production of the new Mercedes-Benz CLA, the first model to feature the Mercedes-Benz Operating System (MB.OS).

Jörg Burzer, Member of the Management Board, Mercedes-Benz Group AG, Production, Quality & Supply Chain Management, commented: “Mercedes-Benz Berlin-Marienfelde remains at the cutting edge of automotive production and keeps Germany on the map as a global centre for innovation. Artificial Intelligence and humanoid robots open up an exciting new frontier which makes automotive production more sustainable, efficient and more intelligent.”

“AI takes over the tasks we usually enjoy less, giving us time to focus on real innovation, creativity and value-adding activities […] So, let’s embrace it as a key part of our solution moving forward”

- Katrin Lehmann, Chief Information Officer, Mercedes-Benz Group AG and Mercedes-Benz AG

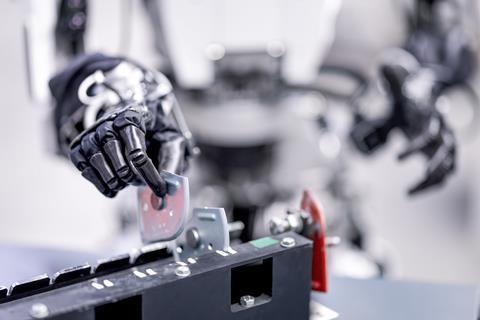

Humanoid robots are quickly moving into automotive production

Mercedes-Benz is taking automation further by integrating humanoid robots into its production lines. The company is testing Apptronik’s Apollo, one of the world’s most advanced commercial humanoid robots, with a particular focus on intralogistics.

Apollo is designed to transport components to the production line and assist with quality inspections. To support this initiative, Mercedes-Benz is investing a low double-digit-million-euro sum into Apptronik, a company originating from the University of Texas at Austin’s Human Centered Robotics Lab.

The automaker has been refining robotics for decades, initially using industrial robots for repetitive and physically demanding tasks. Now, Apollo is being trained in real production environments using augmented reality and teleoperation, enabling human workers to transfer their expertise to the robot.

The next phase of development at Berlin-Marienfelde involves Apollo autonomously performing key production tasks—marking a crucial step towards a flexible, AI-driven assistance system. In December, Apptronik announced a strategic partnership with Google DeepMind to enhance Apollo’s capabilities with cutting-edge AI, pushing the boundaries of robotics in dynamic manufacturing settings.

Read more Robotics and Smart Factory stories

- The robots are here: How humanoids are changing auto production

- Smart Factory: BMW’s digital production at San Luis Potosi, Mexico

- Cobots in support of vehicle manufacturing

- Smart factories and partners power JLR’s circular seat foam

AI-powered assistance for the vehicle manufacturing workforce

Artificial intelligence is reshaping Mercedes-Benz’s production ecosystem, making digital tools more accessible and intuitive. The MO360 AI Factory enables employees to interact with AI-powered assistants for streamlined decision-making. The in-house Digital Factory Chatbot Ecosystem, for instance, allows workers to retrieve production data, seek maintenance guidance, and access best-practice methodologies simply by posing questions in multiple languages.

”I’m convinced that it [AI] makes a significant contribution to business success when applied strategically and executed pragmatically”

- Katrin Lehmann, Mercedes-Benz

Katrin Lehmann, Chief Information Officer, Mercedes-Benz Group AG and Mercedes-Benz AG, said: “AI takes over the tasks we usually enjoy less, giving us time to focus on real innovation, creativity and value-adding activities. I’m convinced that it makes a significant contribution to business success when applied strategically and executed pragmatically. So, let’s embrace it as a key part of our solution moving forward.”

Another AI-driven innovation is the virtual multi-agent system, which analyses production data in real time to identify quality deviations and operational inefficiencies. Rather than relying on laborious manual assessments, engineers now use AI agents to detect anomalies, recommend corrective actions, and optimise processes with unprecedented speed and precision.

Marienfelde’s role in Next-Generation motor production

Beyond digitalisation, Mercedes-Benz is reinforcing Berlin-Marienfelde’s role as a centre of excellence for electric powertrain production. The facility is preparing to manufacture high-performance axial-flux motors, a technology that enhances power density while reducing weight and space requirements.

Axial-flux motor production at Marienfelde will involve approximately 100 distinct processes, 65 of which are new to Mercedes-Benz, with 35 entirely new to the automotive industry.

Engineers have developed proprietary methods involving laser technologies, bonding techniques, and AI-enhanced assembly, resulting in over 30 patent filings. This array of advances is pushing Marienfelde into a position of leadership in production process innovation.

No comments yet