General Motors is set to invest $920m in its Duramax diesel engine production facility in Brookville, Ohio to quadruple its footprint.

GM said the investment will support the production of internal combustion engines (ICE) set for use in its heavy-duty truck line, adding 1.1m sq.ft to the 250,000sq. ft facility.

Announcing the expansion at the plant, which originally opened in 1999, Michael Trevorrow, vice president of North America Manufacturing Operations, GM, said: “This is to continue to support the internal combustion engines that our DMAX team makes for our heavy-duty trucks.”

Construction is due to begin immediately. “We’re already starting to move dirt. This is an important investment and strengthens our industry leading truck business,” Trevorrow said. “In 2022, we delivered the largest year-over-year improvement in market share for this competitive segment. Our increase was to 288,000 trucks for the year which was about a 30% improvement. But even with that improved supply base that drove those great numbers last year, there is still increasing demand for our heavy-duty trucks. The large DMAX expansion will help us get more trucks to our customers. GM doesn’t make investments like this without great trust in our workforce.”

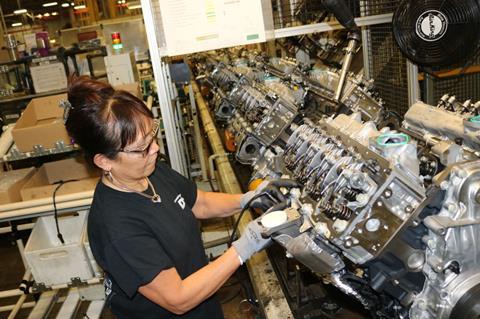

The Ohio DMAX plant provides diesel engines for heavy-duty Chevrolet Silverado and GMC Sierra pickup trucks. Since it began production in 2000, the plant has produced more than 2.7m Duramax engines.

Over this last decade, GM has invested $32 billion into its manufacturing and parts distribution facilities. While there has been a rising trend towards electric vehicle (EV) production, the carmaker has made sure to steadily invest in its traditional ICE vehicles alongside new EV and battery manufacturing facilities.

On the ICE production side, GM announced last week that it would be investing $632m in its Fort Wayne Assembly plant for the production of its next generation ICE trucks. This will fund new conveyors, tooling and equipment in the plant’s body and general assembly areas for the new full-size trucks.

The carmaker is also putting $500m into its Arlington Assembly plant for future ICE SUVs, subject to local regulatory approvals. On top of this, GM announced earlier this month that it would be investing $1 billion into its Flint, Michigan ICE truck plants. The carmaker is set to put $788m into its assembly facility updates including a body shop building expansion, general assembly conveyor expansion and new tooling and equipment. Its Metal Center will receive $233m for new stamping dies as well as press refurbishments and new equipment.

It is also funnelling funds into its electric vehicles (EVs), having announced plans to build a battery material facility in North America at the start of June. GM is partnering with POSCO Future M for the second phase of their joint venture, estimated to exceed $1 billion, to help create a more secure EV supply chain.

The plans are the latest in a string of EV supply chain developments from GM. In April, GM partnered with Samsung SDI to build a new $3 billion battery cell manufacturing plant in North America. The plant will begin operations in 2026 and have more than 30GWh of capacity, bringing GM’s total US battery cell capacity to about 160GWh when at full production. GM and POSCO Chemical also partnered in March last year to announce a new plant for CAM processing in Quebec, Canada. In 2022, GM announced it would be spending $6.6 billion across Michigan to construct a new manufacturing plant and develop EV pickup production.

No comments yet