Quality

Honda looks to master flexibility to futureproof production operations

Honda North America’s newly upgraded production operations in Ohio are going to be the OEM’s template for flexible production of ICE, hybrids and EVs on a single line.

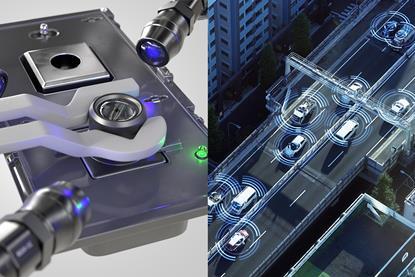

Henkel provides next-generation gap filler solutions for automotive electronics

As vehicles evolve into high-performance computing platforms, thermal management is critical. Henkel’s next-gen gap fillers are engineered to handle rising heat loads in compact, power-dense automotive electronics, tackling heat in compact ECUs and battery modules, supporting safe, high-density automotive electronics for EVs and ADAS.

Digital threads weave together connected car factories

Digital twins and AI are reshaping connected car factories, promising leaner, smarter and more resilient automotive manufacturing.

Register now: Automotive Gateway Mobilizer - Mastering Communication Challenges in Battery and EV Components End-of-Line Tests

In this this product showcase HMS will present solutions supporting battery and EV component end-of-line tests.

ArcelorMittal’s Multi Part Integration optimises production

ArcelorMittal’s Multi Part Integration solution simplifies manufacturing, cuts costs, improves safety, and reduces CO2 emissions, meeting the evolving demands of the automotive industry.

New whitepaper: BASF and Catena-X: Creating a more connected and efficient automotive industry

This whitepaper provides an in-depth look at how BASF, as a top 30 global automotive supplier, is leveraging Catena-X to enhance supply chain transparency, ensure regulatory compliance, and drive efficiency.

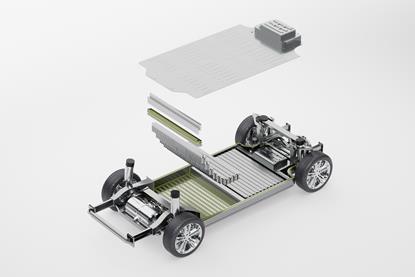

Henkel speeds up EV battery development with simulation

Henkel’s in-house battery simulation team is cutting EV development time by replacing physical testing with data-driven modelling

PTC integrates ALM and PLM to drive automotive innovation

Find out how integrating ALM and PLM systems boosts efficiency, fosters collaboration, and ensures compliance in the evolving automotive industry.

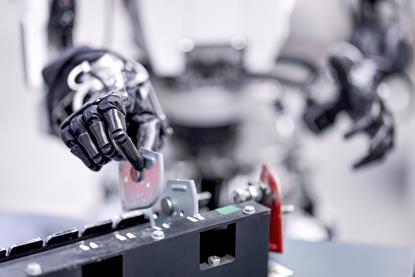

Mercedes-Benz advances AI and robotics in production

Mercedes-Benz is redefining production at Berlin-Marienfelde with AI and humanoid robots, pioneering digital manufacturing methods for a more intelligent future.

Henkel’s advanced thermal management for ADAS reliability

ADAS domain controllers generate extreme heat, threatening performance and longevity. Henkel’s latest thermal interface material ensures efficiency and reliability.

Honda upgrades production with advanced processes for 2026 Passport models

Innovative manufacturing enhances efficiency, quality, and ergonomics at Alabama Auto Plant.

Europe’s $208.4bn AI investment to catapult automotive production

The EU’s InvestAI fund will drive AI adoption in automotive, supercharging manufacturing with smart factories, enhanced automation, next-gen production technologies.

Honda North America’s big investment in flexible manufacturing for EVs, hybrid and ICE vehicles

Honda invests $1 billion in retooling its Ohio manufacturing plants to build ICE, hybrid, and EV models on same production line.

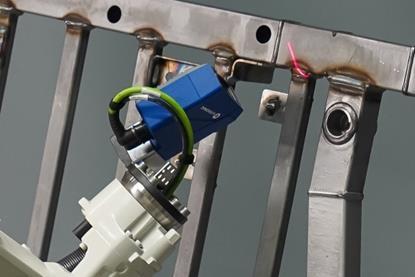

Audi wants to define new standards for AI image processing

Audi is driving AI innovation in vehicle production with advanced image processing, eliminating errors and setting new quality benchmarks for the smart factory era.

Digital twins: faster, more transparent production planning

In this AMS livestream, the first in a new series focused on smart factory and digitalisation, our editors and experts examined how digital twins are being scaled for large and small automotive production projects.

Register now - Futureproofing factories: Agility and flexibility in production

This AMS livestream will explore how manufacturers are using digital tools to optimise current production lines for flexibility and futureproof planned facilities, including layout optimisation, flexible automation and planning for flexibility.

Register now - Shopfloor tools: Human-centric digitalisation in production

This AMS livestream will spotlight how advanced digital tools and automation can be best geared to support manufacturing associates, including shopfloor workers and engineers, to maximise value-added activities, increase quality and improve safety.

Data-driven decision-making for sustainable automotive production

Data-driven decision-making is revolutionising automotive manufacturing. By leveraging AI and big data analytics, OEMs and suppliers are optimising operations, minimising waste, and achieving ambitious sustainability goals.

Thomas Dose on BMW Chennai’s growth and embracing diversity

BMW Chennai’s head, Thomas Dose, discusses his career path, challenges in India, and the importance of diversity in manufacturing.

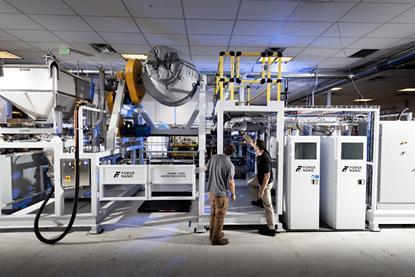

GM Ventures invests $10m in Forge Nano to improve EV battery performance and reduce costs

General Motors and Forge Nano have entered a strategic partnership agreement to collaborate on atomic layer deposition applications for GM’s electric vehicle batteries.

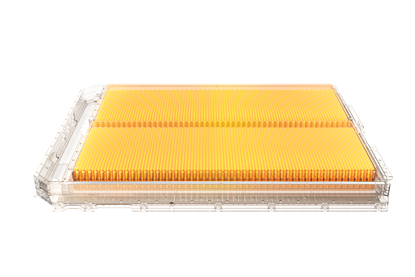

New eBook: Better, faster, more affordable EV battery manufacturing

A new eBook by Hexagon explores insights to help you make high quality, low cost EV batteries.

How cobots can support automotive production

Cobots enrich the industry with their ability to complete tasks in close cooperation with humans and are becoming increasingly intelligent thanks to modern technologies.

EV battery testing – new software supports testing rapidly changing battery technologies

New battery technology is being developed, and testing companies are focused on the same old parameters. But change could be on the horizon with new software.

European battery production needs greater speed and agility

Exhibitors at this year’s Battery Show in Stuttgart shared insights into EV and battery production challenges and how the industry needs to adapt with greater speed.

In Emden, VW wants to leave the Passat behind

Volkswagen is using the latest production technology and some novel in-plant logistics to ramp up EV production in Emden

Designing manufacturing systems for flexibility and scalability

Comau discusses assembling e-drives, developing battery manufacturing solutions, and collaborations with universities for next-generation cells.

Hyundai’s Metaplant America begins 2025 IONIQ 5 production

Hyundai Motor Group Metaplant America has revealed plans to kick off production of the 2025 Hyundai IONIQ 5, marking a significant milestone in electric vehicle manufacturing.

BMW opens first North American press shop at Spartanburg, debuts new X3

BMW’s Spartanburg plant opens a $200M press shop, introduces new X3, and announces all-electric vehicle production by 2026

Quality data drives F1 peak performance

High quality components and manufacturing data are key to on-track success. Oracle Red Bull Racing offered AMS a glimpse of its engineering operations.

Sames solves for BMW & Mercedes: Adhesive tech in bodyshop & glazing

Sames innovates with custom adhesive solutions for BMW & Mercedes, enhancing carbon fiber body assembly and glazing applications with tailored systems and rigorous testing.

Exclusive: BMW Group improves efficiency with additive manufacturing gripper

AMS visited BMW Group’s Additive Manufacturing Campus and plant in Munich to see it 3D-printed bionic robot grippers, which are saving costs and emissions and improving efficiency across its plants.

Q&A with Patrice Haettel: CEO of powertrain tech firm, HORSE

We interviewed powertrain producer HORSE’s CEO, Patrice Haettel, to talk battery tech, flexible production, sustainability, data, digitalisation, and more

OEMS agree co-creative collaboration is key

We need to work together. That much is clear. The need for closer collboration and co-creation through this closer working is key to automotive. Across manufacturing, design and engineering; a wider view is necessary for the progress of the whole. This is a theme that keeps croppping up and Design4Production reemphasised this need once again…

How Mercedes-Benz and Seat are transforming their plants

Both Mercedes-Benz and Seat are transforming their plants to increase sustainability and digitalisation, but it hasn’t all been smooth sailing.

Balancing digitalisation with production output

Automobil Produktion Kongress 2024 brought together leaders in the industry to disuss the growing importance of digital transformation in manufacturing

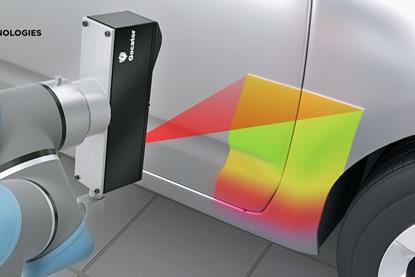

Quality control: 3D vision inspection systems

LMI Technologies offers insights into current trends in automotive quality control requirements and the technology solutions available.

BMW builds gigafactory for Neue Klasse in Mexico

BMW Group has started construction of a battery manufacturing facility next to its San Luis Potosi plant in Mexico to safeguard Neue Klass production in 2027 and cut transport emissions

Perfecting paint transfer

The paintshops an area where throughput, quality and sustainability need to be carefully balanced. Sames, looks at key areas where efficiencies can be made.

Toyota invests $1.4B in US manufacturing for new BEV SUV

Toyota ramps up its commitment to US manufacturing with a $1.4 billion investment, bringing an all-new battery electric SUV to Indiana

Audi: “We have a clear strategy towards electromobility”

Gerd Walker illuminates Audi’s innovative strategies for sustainable, flexible production and the transition to electric vehicles

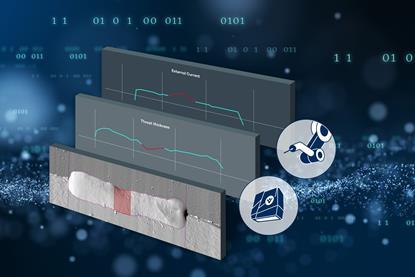

Artificial intelligence – New developments in surface inspection

AI and automation are becoming key technologies for surface inspection in the paintshop.

Reshaping the future: Developments in automotive production engineering

A picture of the fast-paced world of automotive production engineering as it navigates the transition to electric vehicles and digitalisation

Compas wins category for site transformation at FYA: Interview with Santiago Jurado, chief quality officer

Santiago Jurado, chief quality officer at Compas talks managing complexity across different brands (Mercedez-Benz and Nissan) and several architectures on a single production line as the company takes category win at the Factory of the Year Awards.

Bridgestone commits record €207m investment in Burgos tyre plant, Spain

Bridgestone’s Burgos initiative aims to boost productivity by 20% to meet the rising demand for premium tires in Europe. By implementing automation, expanding vulcanisation capacity and introducing an automatic high bay warehouse, Bridgestone looks to leverage BCMA for enhanced operational efficiency and agility.

“Our future viability is not a given”: BMW Leipzig’s plant manager Petra Peterhänsel

BMW Leipzig has a unique approach to its production operations and we explore its approach as it prepares for ramp-up of the Countryman: Petra Peterhänsel offers valuable insight

Toyota Alabama Launches i-FORCE line enhancing Tacoma’s performance

The launch of the i-FORCE 2.4L turbo engine line for enhanced Tacoma at Toyota Alabama affirms the OEMs commitment to diversified powertrains and job security

Powertrain – Reducing waste in machining fluids

JLR offers a very interesting sustainability case study on powertrain production processes at its Electric Propulsion Manufacturing Centre.

Porsche plant in Leipzig wins Factory of the Year

The Porsche plant is set to begin producing the new all-electric Macan SUV using the PPE platform.

The co-evolution of EVs, architectures and production processes

Electric vehicles are reshaping manufacturing norms, from platform flexibility to crash protection systems, challenging traditional designs and material choices amidst evolving battery technologies. ArcelorMittal and Gestamp dive into challenges and solutions.

Henkel supports innovation with Battery Engineering Center

Experts at Henkel, a global leader in adhesives, sealants and functional coatings, explain the benefits of the new Battery Engineering Center, and how it solidifies Henkel’s role as a premier design and innovation partner for OEMs in the automotive industry.

The state and stipulation of automotive production: Retrospect 2023 to prospect 2024

In 2023, the automotive industry underwent a transformative journey, adapting to trends such as sustainable materials, electric vehicle dominance and digitalisation. But what clues does 2023 provide about the vehicle manufacturing landscape in 2024?

AMS Winter 2023/24 – BMW’s battery boost

BMW is aiming to achieve ‘expertise in every cell’ of its generation six batteries

Additive manufacturing and simulation technologies: an agile and resilient powerhouse in engine development

Punch Torino elevates automotive engine production through collaboration with Markforged, a leader in additive manufacturing. This partnership fuels the creation of 3D-printed tools, including camshaft locking tools and simulation technology. By tackling crucial challenges and streamlining design iterations, the partnership achieves enhanced efficiency, cuts costs and contributes to the promotion of sustainable mobility within the automotive industry. Here’s how…

How battery and electric motors and EVs are reshaping the European automotive supply chain

How major automakers adapt to the EV surge, transforming manufacturing and supply chains. Delve into the strategic shifts at Ford, JLR, and Volkswagen, the rise of Chinese suppliers, and the regulatory forces reshaping the automotive landscape. Join us on a concise journey through Europe’s electrifying automotive future

Renault announces Re-Industry roadmap to transform production base

Renault Group’s Re-Industry initiative aims to transform its manufacturing base for cost efficiency and sustainability by leveraging the Industrial Metaverse, AI applications, and agile practices.

JLR accelerates digital transformation with Tata connecting 128 global sites

JLR partners with Tata Communications to revolutionize its digital network, paving the way for enhanced production, real-time data analysis, and seamless connectivity across its global operations. A key milestone in JLR’s Reimagine strategy.

Stellantis’ FBD brainstorms to solve automotive production challenges

The eighth instalment of Factory Booster Day produced ninety-nine solutions demonstrated by sixty-four partners to tackle thirty-five Stellantis plant challenges setting an example to other OEMs

Advanced materials application for EV battery production

SAMES discusses how its technologies and experience can be instrumental in ensuring the quality and safety of EV batteries.

How BMW will maintain quality in its 3,000-step battery cell production process

At its recently opened German Cell Manufacturing Competence Centre (CMCC) in Parsdorf, BMW is aiming to achieve ‘expertise in every cell’ of its generation six batteries for its Neue Klasse EV models.

Hyundai partners with PIF for automated production plant in Saudi Arabia

Hyundai Motor Company has entered into a joint venture agreement with the Public Investment Fund (PIF) of Saudi Arabia to establish “a highly automated vehicle manufacturing plant,” in the kingdom. Hyundai to lead as as strategic technology partner.

Back in the USA

The AMS Automotive Evolution North America event delivered expert panels and a fully engaged audience. Here are some of the highlights from the sessions.

The future of Ford in a flash of lightning

The Ford Dearborn Truck Plant is a benchmark for managing complexity, quality and software. Plant manager Corey Williams shares learnings and lean principles across ICE and fast-growing EV output.

Watch: Automated weld seam inspection of EV-battery trays with VIRO WSI

An EV battery tray typically has many welds. But even one defect weld risks stability, tightness, and safety

Skoda Kvasiny to become electromobility powerhouse

Head of Skoda Kvasiny plant, Miloš Halbich discusses how the plant continues to evolve to meet market developments

How Vitronic’s Weldloop software reimagines the welding process

Find out how Weldloop’s technology achieves quality enhancements in automotive welding through machine vision technology.

New motor technology to transform electric vehicle production

Opher Doron of EVR Motors describes how a novel electric motor design could have a dramatic impact on vehicle production and the electric vehicle market

Volta Trucks partners with ZF Commercial Vehicle Solutions for core systems for its all-electric urban delivery truck

Scandinavian electric vehicle OEM, Volta Trucks, partners with ZF Commercial Vehicle Solutions (CVS) to leverage their expertise and technologies

Supporting ADAS – AMS Expert Interview with Henkel

In this podcast we look at the production challenges and solutions for high-resolution camera modules in ADAS vehicles

Forming innovations – press shops get smarter

Digital tools are playing a major part in innovating press shop operations with data gathering and AI increasing the visibility and efficiency of the forming process

Neckarsulm – Audi’s plant prepares for more electric vehicles

Audi’s Neckarsulm plant manager Fred Schulze discusses sustainability and digitalisation

Case Study: Daimler Relies Upon HiveMQ During Automotive Manufacturing

Learn how and why Daimler uses HiveMQ to manage information flow between vehicle diagnostics system test devices on the factory floor and server-side enterprise IT systems

Heat-treatment – AMS Expert Interview with Nitrex

Jason Orosz, president of Global Heat-Treating Services at NITREX, speaks with AMS about the applications for specialist surface treatments in the latest vehicle components

Focus on flexibility – optimising battery pack production

The AMS Evolution Livestream expert panel representing Ford, AMTE Power and Henkel, discussed fast-changing EV battery production requirements.

Powering up: AMTE ramps up cell production volume

AMTE CEO Alan Hollis discusses ramping up cell production, establishing a new Gigafactory and developing a flexible, sustainable manufacturing approach

Shaping the future – Developing electric vehicle architectures

In our AMS Evolution Livestream experts from ArcelorMittal and Gestamp tackle EV production challenges and explain how digital tools, new technologies, processes and materials innovations could help solve some key issues

Form and function: Developing production processes and structures for electric vehicle architectures

The new electric vehicle architectures are also continuing to evolve as vehicle makers strive to find the optimum balance between platform flexibility, while also being viable for high-volume production. To get some insights in to this ongoing process AMS spoke with Paul Belanger, Gestamp’s R&D Director for North America

Solving electric vehicle production challenges with smart manufacturing and logistics

Siemens discusses how the latest digital tools are enabling the transition to e-mobility and explains why these are now essential to OEMs and tier suppliers if they are to create transparent, sustainable supply chains

Kia starts building facility for electric purpose-built vehicle (PBV) production

The new plant will be dedicated to production of Kia’s electric PBVs, with planned annual capacity of 150,000 units

Sustainability: Fossil-free steel

As vehicle makers set ambitious targets to reduce their carbon footprint in production operations, experts from steel producer SSAB share some insights into how the company has responded to this important requirement with the development of fossil-free steel

Tools for progress: real-time tracking and monitoring in Audi’s toolmaking

The carmaker’s Toolmaking 4.0 system is bringing greater visibility of suppliers and potential disruption of machines and operations at tool shops, with high productivity gains.

BMW Group’s Leipzig plant prepares production of electric Mini Countryman

The company says this will be the first time that a Mini model is produced entirely in Germany

BMW 3.0 CSL going into production at Dingolfing plant this spring

The company is building an exclusive small series with a limited edition of just 50 models. The assembly process for one vehicle will take almost two weeks

Bentley starts work on new Launch Quality Centre and Engineering Technical Centre

Bentley says the new facility will be integral to its preparations for future battery-powered electric vehicle production

Dacia – building on a successful formula

Speaking to AMS, Carlos Carrinho, General Manager Dacia Vehicle plant Mioveni, discusses the factory’s unique position within the realm of European car manufacturing and how it has been continuously developing to meet future production challenges

Honda Alabama starts production of all-new Pilot

Honda’s Alabama plant requires substantial production changes to build all-new Pilot SUV

AMS Winter 2022-23 – M-power in Mexico

In this latest AMS digital edition we have features on BMW’s San Luis Potosi facility in Mexico, Ford’s planned European Electrification Centre at Cologne, CATL’s battery cell production operations in Europe, ZF’s upgrading of its plants for EVs and electronics, and more.

Welcome to Automotive Evolution Europe 2022!

Editor-in-Chief Christopher Ludwig kicks off the 1st Automotive Evolution Europe

Painting a brighter day: increasing speed, reducing errors in paintshop

SAMES and FANUC joined the eighth panel at Automotive Evolution Europe to discuss optimising processes and reducing waste in the paintshop.

Material matters: body, forming and process transformation

Teknia, ArcelorMittal and SSAB joined the seventh panel at Automotive Evolution Europe to discuss how new technology and materials are ushering in new innovations in manufacturing.

Managing an uncertain future in manufacturing

S&P Global Mobility, Magswitch and Next e.GO Mobile joined the fourth panel at Automotive Evolution Europe to discuss the volatile production environment, to which OEMs and suppliers must respond to mitigate disruption to production.

A tipping point: European automotive manufacturing outlook

AMS Automotive Evolution Europe’s third session was a presentation focused on analysis and forecasts for the European automotive sector from S&P Global Mobility.

Data at the heart of Europe’s manufacturing evolution

Audi, BMW and AWS joined the opening panel at Automotive Evolution Europe to discuss opportunities in data analytics, artificial intelligence, digital simulation, the industrial cloud and tools that support them.

AMS Electric Vehicles – The road to e-mobility

In this latest AMS digital edition we will look closely at how manufacturers are developing and finetuning their electric powertrain technologies, platforms and production processes, with in-depth features on Skoda, GM, Ford, Volta Trucks, REE Automotive and more.

After baptism of fire, BMW plant has room to grow in Mexico

Under Mexico plant director Harald Gottsche, BMW has launched new models during the pandemic, navigated supply disruptions, integrated new technology and maintained staff levels – and it’s ready to expand.

Adjusting to a new climate: Alternative powertrain testing

AMS visited a newly upgraded test facility to get an insight into the equipment and process requirements for electric and fuel cell powertrains

The future of quality management in the automotive industry

Siemens discusses how the automotive industry must adapt its approach to quality management to meet new market challenges

White Paper: Nikon’s Laser Radar heralds a paradigm shift in automotive metrology

Nikon Metrology has been implementing automated, absolute measurement on the shop floor for many years. The APDIS Laser Radar is a significant step forward in the evolution of technology and is especially suited for the automotive industry.