- Plant Functions

- Smart Factory

- Register now: Automotive Gateway Mobilizer - Mastering Communication Challenges in Battery and EV Components End-of-Line Tests

- New whitepaper: BASF and Catena-X: Creating a more connected and efficient automotive industry

- Watch now: Digital Transformation at Inflection Point within Automotive Manufacturing

AMS/ABB Automotive Manufacturing Outlook Survey 2024 results

AMS/ABB Automotive Manufacturing Outlook Survey 2024 results

- Electrification

- Automation

- Sustainability

- Events

- Companies

- Materials

- Regions

- Kaizen

- Video and Audio

- Magazine

- Surveys & Reports

- Newsletters

- Partner Content

- Register now: Automotive Gateway Mobilizer - Mastering Communication Challenges in Battery and EV Components End-of-Line Tests

- Watch now: Digital Transformation at Inflection Point within Automotive Manufacturing

Henkel’s advanced thermal management for ADAS reliability

Henkel’s advanced thermal management for ADAS reliability How Henkel is co-developing the EV batteries of the future

How Henkel is co-developing the EV batteries of the future

- Whitepapers

- Media Pack

- Register

- Sign In

By Magswitch

- Previous

- Next

Automation News

Honda looks to master flexibility to futureproof production operations

Honda North America’s newly upgraded production operations in Ohio are going to be the OEM’s template for flexible production of ICE, hybrids and EVs on a single line.

VW’s Bratislava and Pamplona gain strategic production value

VW ramps up production in Slovakia and Spain, shifting key models like the Passat and future EVs away from Germany to cut costs and drive innovation.

“Pure electrical production is not our goal”

Mercedes-Benz Bremen is building 10 models across drivetrains, piloting AI tools and expanding Maybach production—without committing to full electrification.

New whitepaper: BASF and Catena-X: Creating a more connected and efficient automotive industry

This whitepaper provides an in-depth look at how BASF, as a top 30 global automotive supplier, is leveraging Catena-X to enhance supply chain transparency, ensure regulatory compliance, and drive efficiency.

Siemens’ OT networking blueprint: Transforming automotive manufacturing with digitalisation

How a future-ready OT network can drive efficiency, security, and flexibility in smart factories.

Hairpins and horsepower: how JLR’s copper loops are reshaping EVs

JLR is using hairpin winding machines to supercharge EV motor production, blending cutting-edge precision with traditional craftsmanship in Wolverhampton.

BMW powers up Debrecen plant for Neue Klasse rollout

BMW’s Debrecen plant comes online with modular EV assembly and just-in-sequence logistics as it prepares to build the next-gen BMW iX3 from late 2025.

Future-ready: BMW’s digital transformation of its Munich plant and beyond

BMW isn’t just adapting its product portfolio it’s reengineering the entire production operation, prioritising flexibility, digitalisation, and long-term operational efficiency.

JAC expands Mexican plant to boost EV and truck output

JAC Motors is expanding its Mexican plant to raise output by 30% and build EVs, trucks and pickups, targeting 60,000 units and future-proofing local production

JLR creates 150 EV manufacturing roles in the UK

JLR is recruiting 150 EV technicians in the UK to support the production of Range Rover Electric and next-generation battery and drive unit manufacturing.

From battery maker to EV leader: BYD’s strategic rise

How BYD achieved global production growth with vertical integration, platform standardisation, automation, and global supply chain finesse

The urgency for enhanced Design For Manufacture (DFM) in vehicle production

This is how Design For Manufacture is transforming automotive production with digital tools, collaboration, and agile strategies as Chinese OEMs outpace global rivals. With Western carmakers falling behind, expansion is critical.

AMS/ABB Automotive Manufacturing Outlook Survey 2024 results

The AMS/ABB 2024 survey reveals key automotive manufacturing trends, from rising costs to trade disputes and the shift to smart factories.

Revolutionising Automotive Manufacturing: Flexibility, Efficiency, and Sustainability with Siemens

Discover how Siemens’ innovative solutions empower automakers to meet the challenges of EVs, sustainability, and smart manufacturing. Download the whitepaper to explore actionable insights.

Europe’s $208.4bn AI investment to catapult automotive production

The EU’s InvestAI fund will drive AI adoption in automotive, supercharging manufacturing with smart factories, enhanced automation, next-gen production technologies.

Rockwell expands with Clearpath Robotics acquisition

Rockwell Automation completes its acquisition of Clearpath Robotics and OTTO Motors, expanding its autonomous material handling capabilities in smart factories.

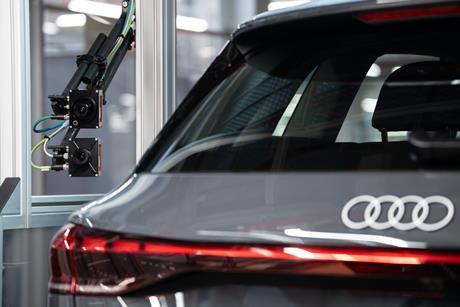

Audi wants to define new standards for AI image processing

Audi is driving AI innovation in vehicle production with advanced image processing, eliminating errors and setting new quality benchmarks for the smart factory era.

BMW drives CO2 reduction with workforce engagement

BMW’s strategy for CO2 reduction goes beyond targets, embedding sustainability into operations, workforce training and leadership incentives.

The robots are here: How humanoids are changing auto production

Explore the emerging role of AI-powered multipurpose at BMW, Tesla, and Mercedes-Benz, and what the future holds for robotics in manufacturing.

Data-driven decision-making for sustainable automotive production

Data-driven decision-making is revolutionising automotive manufacturing. By leveraging AI and big data analytics, OEMs and suppliers are optimising operations, minimising waste, and achieving ambitious sustainability goals.