Dürr explains how, a variety of different materials are being used to construct the latest models hitting the market, and paint lines need to adapt accordingly

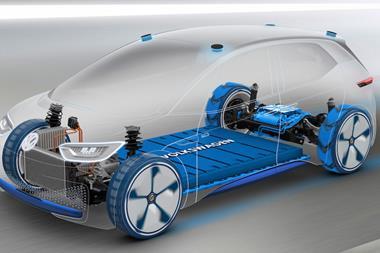

The future belongs to electric vehicles (EVs), since they allow emission-free and sustainable mobility. The established car manufacturers are increasingly being joined in the market by new competitors, especially in China. Dürr is currently building a fully automatic paint shop for a local OEM. The plant in Hefei is designed to handle 100,000 units per year, and will commence operation in June 2018. The integration of numerous digital@DÜRR solutions turns the paint shop into a smart factory with extensive use of data.

The future belongs to electric vehicles (EVs), since they allow emission-free and sustainable mobility. The established car manufacturers are increasingly being joined in the market by new competitors, especially in China. Dürr is currently building a fully automatic paint shop for a local OEM. The plant in Hefei is designed to handle 100,000 units per year, and will commence operation in June 2018. The integration of numerous digital@DÜRR solutions turns the paint shop into a smart factory with extensive use of data.

The new JAC (Anhui Jianghuai Automobile) plant will produce battery-powered cars on behalf of a local electric car manufacturer in the future. The vehicles will be given a modern two-tone colour design in the fully automatic Dürr paint shop. The plant combines advanced vehicle drives with intelligent production technology and modern painting concepts. The entire plant including data acquisition, data evaluation, and plant monitoring is controlled by the Dürr software solution iTAC.MES.Suite. The modular MES system provides detailed information on the production workflows and the consumption data at all times.

Adapting paint processesEVs are also increasingly featuring plastic and lightweight components, which are painted separately and not installed in the body until the final assembly line. The workflows in the painting lines are adapting to these changes. Before the bodies are given their top coat in the painting booth, they undergo pretreatment (PT) and electro-coating (EC). The RoDip rotational dip process is used to apply the corrosion protection coating. The rotational movement of the bodies does away with the need for entry and exit inclines at the tank, saving a considerable amount of space. The smaller tank capacity means that RoDip uses less energy, water, and chemicals, and in this way reduces the costs per unit.

Then the seams on the underbody are sealed, a flat underbody protection is applied, and sound deadening mats are applied to the inside of the body. This is done using the new EcoGun2 3D applicator, which is suitable for all sealing materials and processes. The new channel layout in the applicator head results in a longer service life and a lower pressure level during material feeding. The innovative applicators are mounted on a total of eight EcoRS 16 or EcoRS 30L16 robots, which apply the sealing material to the bodies.

The painting line itself consists of a primer station as well as one interior and two exterior painting stations for the top coat. Here the bodies are removed in some cases and returned to the top coat line for the two-tone roof painting. The final clear coat is also applied in fully automatic interior and exterior painting stations. In order to reduce the solvent emissions as much as possible, the exhaust air flow is purified, not only from the clear coat booths, but also from the paint mixing rooms.

Usually the painting process generates particularly large volumes of exhaust air which only contain low amounts of contaminants. For this reason, a highly efficient VOC adsorption concentration system (Ecopure KPR) with a downstream thermal exhaust air control system (Ecopure TAR) should be installed. The energy required for the Ecopure KPR system’s desorption air is recovered from the purified gas of the thermal exhaust air purification system. This reduces the energy requirement. The highly efficient Dürr Ecopure exhaust air purification system reduces the solvent emissions by more than 95% and thereby ensures that the especially stringent emission limits are not exceeded.

Fully automatic paint application is handled by a total of 26 EcoRP E/L033 and EcoRP E/L133 painting robots. Eight EcoRP 130 scara robots support the painting process by opening the doors and one EcoRP 133 opens the hood at the front. The trunk lid as well as the fenders are made from plastic on EVs, and are not mounted on the body until late in the production process. There is therefore no need for a trunk opener at the rear.

This paint shop is the first time the EcoBell3 Ci atomisers from Dürr are being used by a local Chinese car manufacturer. They are particularly suitable for painting interiors using water-based paints and require no complex voltage block systems. The compact design enables the atomisers to get into each and every angle inside the body. The robust high-voltage technology produces minimal inherent soiling and delivers top quality and paint application efficiency. Short rinsing and colour change times as well as fast cleaning intervals in combination with the EcoBell Cleaner D2 increase the paint shop capacity and the productivity.

Smart systemsIndustry 4.0 is the keyword for the digital evolution of classical production technology into the smart factory. With its digital@DÜRR approach, Dürr offers a wide range of solutions. This includes not only the production control iTAC.MES.Suite, but also the integration of a new software solution for fresh and exhaust air control with the ovens in Hefei. Dürr’s EcoSmart VEC smart air management system operates fully automatically, delivering energy on demand. This technology significantly reduces gas and electricity consumption when drying the freshly painted bodies. With conventional oven systems heated using purified gas, the fresh air supply system and exhaust air extraction system are operated with a constant volumetric flow rate.

Durr’s EcoSmart VEC smart air management system, on the other hand, is a predictive control system. It controls the volumetric flow rate of the fresh and exhaust air depending on the current number of vehicles in the oven and their position.

The system therefore ensures that each individual oven zone is optimally and individually supplied with air at all times, and combines energy efficiency and consistently high paintwork quality. The exhaust air from the ovens is purified via the integrated Ecopure TAR afterburning system with heat recovery and then made available again for the oven heating system. The new version of the EcoScreen 3D-OnSite operating software features further smart programming and simulation options. The software is the perfectly coordinated tool for parameterising, programming, and simulating Ecopaint robots. The new 3D kernel supports all popular CAD data formats.

The EcoRPC robot controller provides smart test functions like valve, brake, or pump tests, which give a detailed picture of the status of the plant technology at any time. The results of the tests are visualised using traffic light functions. This allows the paint operator to easily tell whether, for example, a valve needs to be replaced immediately or whether everything is working reliably in the green range.

Another smart software function of the EcoRPC controls the interaction of the main needle in the atomiser and metering pump. The self-learning system enables high-precision switching points for the robots’ painting paths and at the same time determines the wear to the pump and needle. The sensor-based paint pressure control system also ensures minimal mechanical load on the pump, as well as a constant discharge rate and therefore constant process quality.

The robot controllers can be easily incorporated into a centralised data network for the smart factory of the future, and have the capability to transmit all process-related information from the sensors and actuators as data stream to higher-level maintenance and control systems at the customer’s site or to the Dürr Service Cloud.www.durr.com