New interfaces for simple and robust communication between production plant and measuring system are the key to the advance of Industry 4.0

The most important measure for optimising manufacturing processes is quality control involving measurement, analysis, and correction processes. In recent years, the three-dimensional digitising of the actual states of finished and semi-finished products, tools, and machines has formed the respective basis. In Industry 4.0, the use of the resulting 3D measuring data will open up new possibilities.

The most important measure for optimising manufacturing processes is quality control involving measurement, analysis, and correction processes. In recent years, the three-dimensional digitising of the actual states of finished and semi-finished products, tools, and machines has formed the respective basis. In Industry 4.0, the use of the resulting 3D measuring data will open up new possibilities.

Within the modular structured smart factories of Industry 4.0, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralised decisions.

To illustrate it: In press shops all machines would work connected and transparent. Process parameters, such as tool temperatures or geometrical information of the produced components, would be recorded by appropriate sensors and made available at any time. The automatically verification of these parameters would speed up the start of correction measures due to a self-regulated troubleshooting, which minimises machine downtimes.

The quality control is thereby designed to accompany the production process, which in turn saves time and money. In Industry 4.0 a press, for example, would independently report that the pressing power deviates from the specification and could independently regulate itself. Also, wear and maintenance intervals will be foreseeable and thus the overall plant efficiency will be increased.

Hurdles for the industry in the past, especially while using tactile measuring systems, included: 2D, paper-based drawings (analogue); no standard inspection language; and gaps in understanding between design, engineering and metrology. The conclusion seems that tactile metrology is outdated and unsuitable to do Industry 4.0. In contrast, optical metrology offers digital, full-surface data (non-contact) with measuring hardware and software that enable users and machines to easily analyse measurement data without expert knowledge. However, to reach a smarter production the complete part information and condition is needed – without unchecked areas. Therefore, optical measuring is indispensable.

Drawing-free product manufacturingConcepts such as PLM (Product Lifecycle Management) are meant to gather as much information related to processes and components as possible in order to manage and control the production chain in its entirety and throughout the company. One has to keep in mind that in addition to the design data and the production information, the inspection features represent an important part of the product manufacturing information. Today CAD software modules such as FTA (Functional Tolerances and Annotations) and MBD (Model-Based Definition) are used to integrate and transport these inspection information. As a result, designer as well as production and measuring engineers have access to all relevant information from the outset and throughout. An essential condition for this kind of data management is, of course, that all information is gathered and transmitted digitally and always kept up to date. In addition, a consistent language is required, which is understood by all involved departments.

Digital inspection feature processingThe latest trend is the anchoring of inspection features and specifications directly digitally on the 3D CAD data set. This means that inspection features or nominal elements such as datum systems, GD&T, dimensions etc. are constructed or implemented with the help of a semantic “construction”.

A preplanned inspection on CAD during the part design, i.e. before producing the component, is a huge step of leaving the analogue world behind and entering a completely digital world. The German company GOM is already able to import features such as FTA elements directly into its measuring and inspection software for an effectively automatic evaluation of actual data.

It is conceivable that geometric dimensioning and tolerancing (GD&T), which is a standard inspection language based on ASME and ISO standards, will be used as standard language in general. In the injection moulding industry, it is already widely used to define engineering functional tolerances of a component. Once the information on a component’s tolerances is digitally integrated into its production data, it is part of the PMI data and thus available within the entire manufacturing process.

However, it is clear that a consistent “language” in inspection and quality assurance for shape and dimension analysis leads to clear information, functional demands on products and efficient production and verification. It means fewer possibilities of interpreting inspection features differently and thus saving time. In such an operation, quality assurance is not an additional and time-consuming step at the end of production, but improves the entire production process.

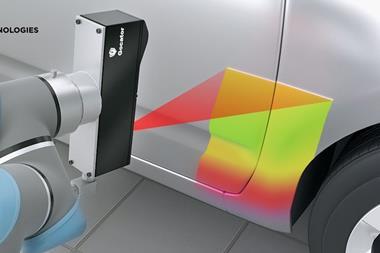

Inline metrology set gain groundBesides the consolidation of common inspection languages companies are contributing to Industry 4.0, by developing new interfaces for a simple and robust communication between machines (production and measuring). One pioneering example is the production of doors and closures for the latest VW Golf in Wolfsburg, where GOM systems already monitor the quality of bonnets, tailgates and doors on individual production lines in a total of 12 stations.

Further, a number of new manufacturing and repair processes are emerged from the combination of high-resolution 3D measuring data and CAD/CAM technologies. The use of full field 3D coordinate measuring data for adaptive machining is a further step towards the smart factory. Overall, it is a fact that a digital process chains and full 3D component information can only be achieved with optical measurement processes.

Digital first sampling and virtual assemblyIn future the 3D digital master will allow to displace the first article inspection due to the complete digital manufacturing process – possibly even the inspection language would no longer be needed. Today, the high quality of the measuring results already forms the basis for a virtual assembly. Therefore, prior to the actual physical assembly, the measured parts are virtually aligned, such that information on gap and flush or functional dimensions can be evaluated at an early stage.

All parts can be measured at different locations. Measuring results deriving from different departments like press or body shops or even from suppliers are virtually merged by the manufacturer, where they can be evaluated centrally. This way, a car body can be analysed irrespectively of Meisterbock or cubing. Due to the existing digital information the data set of the virtual assembly can be adjusted at any time. If parts must be exchanged or measured later, a fast transformation into the global data set is possible.

3D inspection facilitates Industry 4.0This makes clear what measuring technology has already done so far and will do in the future. It is no longer just a question of improving product quality, but of improving the entire production process. It is obvious that standardisation and transparency in global product development processes will play an even more important role. The aim is to ensure that all information that affects the vehicle manufacturing is always digital existent and ready-to-call at all times, from the design phase to the finished car. Only this can guarantee that in future, a manufacturing order could be automatically controlled in line with the digital value chain.

No more drawings will be needed since each produced component will be measured completely in 3D. Thus, component faults will automatically be measured and corrected during the manufacturing process.