The last decade has seen the most dramatic and potentially disruptive burst of innovation in braking system development

With new vehicle power sources, increased viability of extensive ‘Driver Assist’ technologies, and a movement towards electronic control and actuation, the challenges facing suppliers and the opportunities offered to designers perhaps seem greater than ever before.

The rapid pace of electronic systems development has involved a complete reconceptualising of brake system architecture. Key to this has been the integration of system functions, including advanced electronic ‘Driver Assist’ systems, along with new approaches to vehicle dynamics management. Braking has become increasingly integrated into vehicle control and dynamics in terms of design, systems and hardware. ZF TRW, for example, has a new Integrated Brake Control system (IBC) featuring a vacuum independent technology that can offer enhanced performance and simplification of packaging issues. It can readily be configured with driver assist and automatic emergency braking systems. ZF’s Slip Control Boost (SCB) system is another innovation replacing the traditional brake actuating system with an electro- hydraulic control unit.

[sam_ad id=17 codes='true']

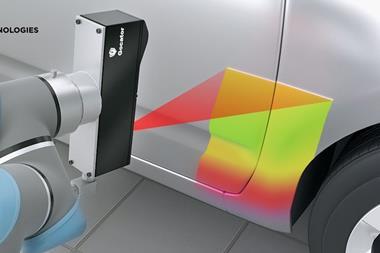

Development in sensor technologies has also become crucial for driver aid systems and sophisticated control of vehicle behaviours. Progress in these areas includes increased use of contactless pedal travel measurement, using magnetic field sensors as well as well as redundant signal recording. Of course, the introduction of ‘brake by wire’ systems has had its difficulties, the early Bosch Sensotronic system adopted by Mercedes some years ago encountered customer resistance and was eventually deleted. Such problems are perhaps inevitable with the introduction of a new and sensitive technology. Increasing use of electric power has added to the importance of regenerative braking capabilities. In hybrid vehicles the interaction of the friction brakes with the recuperative braking is pushing suppliers and manufacturers to ever more sophisticated control mechanisms. They, in turn, demand sophisticated system communication protocols. Control systems capable of torque blending are required to ensure the most efficient energy recuperation, along with vehicle stability and acceptable pedal feel to provide a reassuring driver experience.

Autonomous vehicle technologiesAutomatic Emergency Braking – scheduled to become a standard feature across the US market by 2022 – requires the various vehicle systems to work together in concert, adding to the logic of integration of the braking system. The longer-term prospect of autonomous vehicles has also influenced the way braking systems are being developed. Alongside this more traditional examination, friction characteristics of pad and disc materials continue, while the contribution of the braking system in energy use reduction has become much more important in recent years. Concerted efforts to reduce brake drag have played their part in reducing fuel consumption and emissions. Electronic Parking Brake (EPB) systems are claimed to reduce brake drag. New caliper designs, often in alloy, with reduced residual drag features have also played their part.

Increasingly traditional pathways in braking are being re-examined. So, for example the Brake Assist technologies are moving toward actuation generated by sensing rapid pedal depression rather than the force of depression, which it is claimed produces enhanced emergency brake response. Dynamic rear proportioning is now incorporated in ABS systems to provide enhanced balance and handling performance. Elsewhere electronic park brake designs can now encompass a front axle EPB linked to ABS/SC systems.

EPB control is no longer performed by a standalone ECU, but is increasingly incorporated into the latest generation of vehicle Electronic Stability Control (ESC) systems. EPB is also now being integrated into the main braking system with an enhanced role in emergency braking and operating in conjunction with ESC and ABS control systems offering full four-wheel emergency brake functionality. Flexray communication systems are used to facilitate this integration of function and hardware, while safety-critical system communication remains a major area of research. Various leading suppliers have developed a modular range of components that can be slotted together to give the appropriate level of functionality at low cost. By sharing components the standardisation delivers scale effects and allows new technological advances and enhanced functionality to be incorporated across the model spectrum.

Bendix recently passed the 1.5m unit production mark of its ADB22XTM air disc brake. Since 2009, annual production levels have risen significantly, with the company producing the last half-million brakes in just over a year. “This milestone reflects not only the growth of air disc brakes overall, but the popularity and increasing demand for the Bendix ADB22X among fleets and OEMs alike,” says Nicole Oreskovic, product line director for air disc brakes at Bendix Spicer Foundation Brake LLC. The company is continuing to invest in the development and manufacture of air disc braking systems, Oreskovic noted.

Elsewhere, friction material suppliers remain concerned with the contribution of brake wear particles to emissions, with ongoing research exploring the health impact of different categories of emission and their behaviour in the environment. The future may well see the development of on-vehicle vehicle brake waste material collection systems. Researchers have already pointed to the benefits of using an on-vehicle CBP Modular Brake Wear Debris Collection system that can be incorporated with no significant adverse affects on brake temperatures while brake pad and disc life is improved. With increased legislative concern about air quality, developments of this kind may be important to meet new legislative initiatives. Earlier EU-funded projects under the REBRAKE programme explored in a scientific manner the distribution of micro and nano particulates resulting from automotive brake applications.

They have led to the development of new disc and pad materials as well as surface coatings. These are complex and scientific engineering issues that require rigorous testing and evaluation. Brake system emissions are a major element of the new EU funded LOWBRASYS Project launched early in 2016 with the mission to demonstrate a low environmental impact brake system with a target to halve micro and nano brake particle emission.

As well as investing in its production capacity and capabilities to meet growing demand, it has doubled the size of its North American-based engineering team and increased its testing capabilities. Air disc brake technology is increasing in popularity across the North American market with over 16% of Class 6-8 wheel-ends now equipped with them, an increase of 50% in market share from 2013. It’s claimed this air disc brake design, helps reduce stopping distance and extends the life of commercial vehicle brake systems. Air disc brakes also offer the advantages of quicker pad replacement and longer pad life.

Once fully operational, Brembo’s new brake plant in Escobedo, Nuevo Léon, Mexico, will be capable of producing 2m aluminium calipers per year. The company has invested $36m in the plant, which covers an area of 377,000 sq.ft, and will add sales of over $100m a year. The new site in Escobedo follows the company’s global strategy of localising production close to its customers, and is said to be one of the its more modern and cutting edge aluminium caliper plants, featuring state-of-the-art manufacturing processes that combine high efficiency with the latest technically integrated solutions. Brembo president Alberto Bombassei announced that the company will also start construction of a new foundry, for the production of cast iron discs, adjacent to the new brake plant. With an investment of $93m, the new facility will be operational by the end of 2017, have a melting capacity of approximately 100,000 tons per year, and will cover an area of 269,000 sq.ft. The production from this new plant will be providing components for American, European and Asian OEMs present in Mexico with manufacturing facilities.