As governments set higher requirements on CO2 emissions, fuel economy and production, Docol advanced high-strength steel is helping auto designers to maximise their designs

Future-proofing can be explained as the systematic anticipation of the future, and the design of business processes that can adapt to those anticipated changes. As a designer of automotive components, the following current and foreseeable trends are already impacting the decisions made today in your designs:

Future-proofing can be explained as the systematic anticipation of the future, and the design of business processes that can adapt to those anticipated changes. As a designer of automotive components, the following current and foreseeable trends are already impacting the decisions made today in your designs:

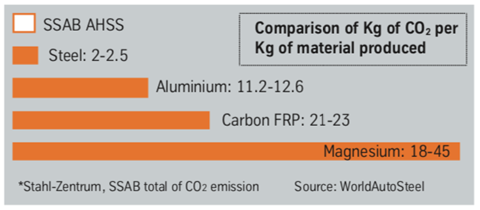

Carbon taxes: These will not only be on tailpipe emissions (which will continue to drive lightweighting for increased fuel efficiency), but eventually taxes could be placed on the vehicle’s embedded carbon, including its production processes and selection of materials.

Growth in EVs: These vehicles present the greatest design and engineering challenges today. For example, how to design a lightweight but exceptionally strong protective cage around large battery packs?

Car sharing: Shared cars mean more intensive use, putting high demands on parts when it comes to reliability, robustness and safety.

Autonomous cars: This means potentially even higher levels of use. Imagine the near-future’s driverless taxi or delivery van that runs 24/7, only stopping to recharge or get its next assignment.

Recyclability requirements: Some countries already require that 95% of the car must be recyclable, reducing or eliminating the use of lightweight materials such as carbon fibre-reinforced plastic (CFRP).

These trends mean designers need to be exhaustive in their search for the lightest, strongest, most recyclable materials that are also the least carbon-intensive to produce, process, and fabricate into their final components. For example, production engineers want to use cold-forming to fabricate steel parts, as it uses less energy and increases production line flexibility (with no extra steps in the process, such as heating of components and laser cutting). Docol martensitic steels are very good at cold forming, with good draw ability and edge-stretching properties.

Maximise your design

Maximising your design simply means the ability of auto parts designers to find materials that allow them to execute as many of their designs ideas as practical. In short, the design should determine the material selection and not the other way around.

The starting point for component materials is typically the OEMs’ specifications for strength, which continue to rise. In response, steel manufacturers are constantly expanding their AHSS (advanced high-strength steel) offerings.

Then come weight considerations. To reduce weight, you want to use the least amount of materials that still meet OEM strength standards. Going thin is less risky if your supplier demonstrates tight tolerances, uniform thickness and material quality. SSAB, for example, always produces the same AHSS grades (eg. martensitic, dual phase, etc.) at the same mill, so their tolerances are very tight and quality is consistent. Another benefit of tight AHSS tolerances are true-to-shape final components that are more precise and therefore easier to assemble – especially during automated assembly.

To maintain strength while using less AHSS, your design’s geometry will probably become more complex. Work with your AHSS supplier to confirm that your trial materials will have the local formability, sheared-edge quality and hole expansion ratios needed for your design. The new Docol HE series has a finer microstructure and improved edge ductility, allowing components with cut edges to be formed with reduced risk of micro-cracks, burrs or failure. Not only does this make a more durable component in the long run, it also helps reduce scrap and avoid the risk of downtime during production.

If the component is to be welded, that might affect which AHSS selection based on alloy content. Your supplier can advise on which works best with which welding process.

What do customers want from component designers?

Consciously or not, customers have expectations from designers of auto components. These include:

A responsive driving experience: Aided, in part, by stiffer components with excellent shock-absorbing properties.

A quieter drive: Especially important in virtually silent EVs –advanced high-strength steel components can be very good at reducing vibrations.

High fuel efficiency via lightweighting: Whether measured by the tank or the charge, customers want to go further.

Low carbon taxes: By reducing their use of petroleum (or fossil-fuel-generated electricity). Soon, buyers will also want to minimise taxes on ‘embedded carbon’ in their car’s production and the materials it is made from.

Low insurance rates: Pound for pound, AHSS steels are exceptionally strong with proven excellent crash behaviour. With higher crash-rated cars, buyers get greater peace-of-mind while lowering their auto insurance premiums.

Reasonable repair costs: Components made from AHSS steels are much less expensive than those made from aluminium, magnesium or CFRP. And most AHSS parts are weldable, further lowering repair costs.

Recyclable: It pains consumers to ‘landfill’ any of their purchases, and future laws will likely make most non-recyclables either illegal or highly taxed. Luckily, steel is 100% recyclable and can be reused infinitely without losing any of its inherent properties.

Future-proofing starts now

As the challenges of climate change grow ever more pressing, global consensus is moving towards ‘bigger picture’ solutions. For designers, a key tool in many of these solutions is Life Cycle Assessment or LCA. True sustainability in mobility, for example, is not merely measured by carbon dioxide from tailpipes (or emissions from power plants supplying electricity to EVs). Instead, products will be measured for sustainability ‘from cradle to grave’ (or, more hopefully with near 100% recycling in the future, from ‘cradle to cradle’.)

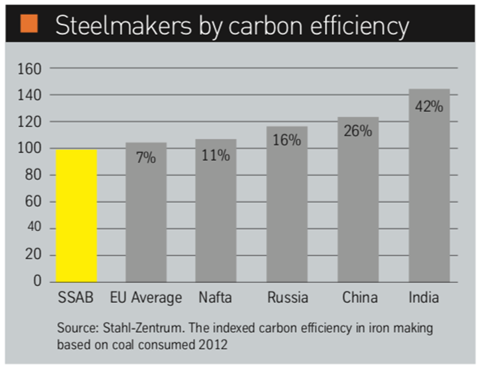

Moving forward to address climate change, consumers and governments will stipulate that manufacturers accurately report the embedded greenhouse gases (GHGs) in all products, as well as GHG production (e.g. emissions) over their anticipated lifetimes, including their final recycling process. In other words, a true Life Cycle Assessment. At first glance, steel suppliers may seem like an unlikely place to start looking for reductions in embedded GHGs. After all, steel mills use vast amounts of coal and coke, annually contributing 7% of the world’s CO2 emissions. That said, AHSS steelmaking is many times less CO2 intensive than the manufacture of other lightweight materials. Furthermore, you can select steelmakers by their carbon efficiency.

Docol advanced high-strength steels are made in the most carbon efficient steel mill in the world. And steel is 100% recyclable for an unlimited number of uses, making it the most recycled material on the planet.

Fossil-free steel production by 2035

Hydrogen Breakthrough Ironmaking Technology (HYBRIT) is a groundbreaking effort to replace coal with hydrogen in the steelmaking process. The joint venture between SSAB, LKAB (Europe’s largest iron ore producer) and Vattenfall (one of Europe’s largest electricity producers), aims to decarbonise the steel industry. leading to emissions of nothing but water vapour. A pilot plant is currently under construction in Sweden, with the goal of offering commercially viable, fossil-free steel by 2035.

HYBRIT will produce iron by using hydrogen gas as the main reductant. The hydrogen gas (H2) will be produced by electrolysis of water using fossil-free electricity, which is already the standard in Sweden. The production route is similar to existing direct reduction processes, except for the carbon dioxide emissions: hydrogen reacts with iron oxides to form water instead of carbon dioxide.HYBRIT is the ultimate in future-proofing, delivering carbon-free AHSS steels that are ideal for EVs and autonomous cars. In the meanwhile, the percentage of AHSS steel in cars will continue to climb as designers utilise its strength and light weight to maximise their designs.

Docol is a registered trademark of SSAB