With sales and production of Battery Electric Vehicles (BEV) increasing, ArcelorMittal says the B-segment will likely be the most popular in Europe and China. Jérôme Favero, head of automotive steel solutions Global R&D, discusses the solutions and opportunities offered by the company’s B-Segment S-in-motion project

The production costs of BEVs are still higher than those of ICE vehicles, and even if the parity is expected in the coming years, the economical context remains difficult with high levels of investment needed, COVID-19 crisis effects being felt with the chip storage, and more recently, the geopolitical situation linked to the war in Ukraine has brought new uncertainties and supply difficulties. As the B-segment is going to be a mass market car, an affordable design is a fundamental requirement.

Within our project we provided a cost comparison of our solution, with the benchmark where possible, to demonstrate steel’s ability to meet the technical requirements at an affordable cost for B-Segment BEVs. Also, we carried out assessments looking at sustainability over the vehicle’s life cycle.

Supporting design and production with a reduced carbon footprint

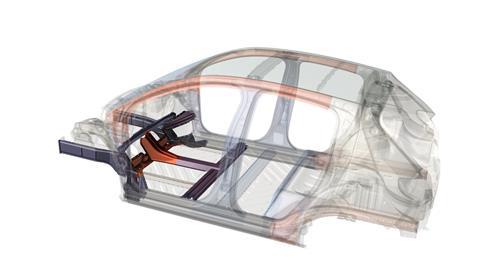

Steel is the dominant material for a car body structure; 57% in mass on average. With a probable switch in midterm from tailpipe emissions to a Life Cycle Analysis perspective, the share of emissions linked to the material selection increases as electrification progresses, because emissions linked to the use phase are being reduced. So, the impact of materials and manufacturing are becoming key. Within our B-Segment S-in-motion project we have focused on different solutions to reduce the carbon footprint of our solution.

The rocker reinforcement is a key area of BEVs which ensures the protection of both passengers and battery pack in the case of a lateral crash event like the pole crash. There are several solutions available that utilise multi-material approaches. For our project, we optimised our steel solution by combining AHSS, such as coated MartINsite, with the roll forming process to make a cost-efficient structure with the required technical performance. We then benchmarked our solution with existing designs.

We could identify in the benchmark a hybrid solution mainly composed of extruded aluminium (63% in mass). After a deep analysis, we arrived at the conclusion that despite the higher lightweighting potential of aluminium, our S-in-motion design could help the car manufacturer to greatly reduce the CO2eq linked to the manufacturing of the part, including material manufacturing, from 24% to 47% depending on the considerations of the end of life and prompt recycling credits, and by considering in both cases the average burden of steel (2,5tCO2eq/t Hot Dip Galvanized) and aluminium (8,6tCO2eq/t) used in Europe. As the benchmarked hybrid solution is lighter, we validated that these gains in manufacturing were not at all compensated by the use phase; the impact of lightweighting on the use phase is low for an average European grid and almost negligible in the case of a green grid.

Even the use of the best-in-class aluminium (5,15tCO2eq/t), the CO2eq emission linked to the rocker production can still be reduced by 19% (with prompt end-of-life scrap credit consideration) to 35% (without prompt end-of-life scrap credit consideration) thanks to steel. In the most representative scenarios, the use phase is not offsetting extra CO2eq emitted to manufacture the aluminium rocker.

“To design a robust S-in-motion concept, we must consider the process impact on material properties and design” – Jérôme Favero, ArcelorMittal

But the steel industry has an important responsibility to reduce CO2eq emissions, and ArcelorMittal has committed to an ambitious development and investment plan that will make the company a major player in this area. The targets set up by the group in Europe are a 35% emissions reduction (scope 1 and 2) by 2030 and to be carbon neutral by 2050 (net zero).

Another benefit of the rocker from our B-Segment S-in-motion project, is affordability which offers a potential 54% cost saving compared to the reference hybrid materials. This would push the hybrid design to €15/kg saved compared to the S-in-motion steel solution, based on average material price from the previous 5 years.

Utilising digital tools to meet forming, joining, performance requirements

To design a robust S-in-motion concept, we must consider the process impact on material properties and design. Spot welding is the most used assembly process in automotive, but it can locally impact on the mechanical properties of the grades and create some weaknesses around the spot; the Heat Affected Zone (HAZ). During a crash loading, the material that constitutes the structural parts undergoes very large deformations for which appropriate failure criteria are necessary, both for the base material and for the HAZ around the welds. Therefore, in our numerical simulation we use specific methodologies to assess the risk of crack propagation from the HAZ to the base material in the case of a crash event.

Failure prediction of the spot welds itself is another important aspect to consider in sensitive areas, to avoid any disassembly if a crash event occurs. Thanks to a large database on the spot weld strength of numerous grades and stack-ups, we were able to establish a digital tool to predict the mechanical strength of the spot welds based on materials and stack-up thickness. Thanks to this approach and our models, we can assess the performance of the assembly in a crash event and be more confident in the solution we propose.

Complex laser welded blanks (LWB) for press hardening with high thickness gaps are another interesting case. Prior to hot stamping, the blanks are heated up to 930°C over several minutes. This operation is to ensure the targeted final mechanical properties and a coating with a good paint adherence and corrosion properties are achieved. However, because of the thickness gap, the heating curve of different sub-blanks will be different; the thicker the blank, the lower the heating speed. To ensure that the process window remains robust to reach targeted properties on part, we have developed a model to predict the transformation that occurs in the aluminium-silicon coating. Using this model, we can assess our design and verify the feasibility of our complex LWBs solutions for hot stamping, regarding the final properties of the part.

We have also developed material cards to evaluate the formability of our grades, with different software and guidelines to use them. Some of our most recent developments are methodologies to provide material cards with models and recommendations for spring back prediction and management of AHSS.

Case study examples of new developments and applications

As well as rockers, another key application to ensure structural integrity and passenger safety in the case of a lateral crash are the floor reinforcements for the Body in White. For this application press hardening steels are the most attractive solution in terms of weight. LWB solutions are proposed for the cross members in Usibor 2000 for anti-intrusion performance, and Ductibor 1000 in the ends for energy absorption. This solution leads to a potential weight saving of 20% compared to the reference in multi-part options combining Usibor 1500 and DP600. And to optimise the weight even further, a Multi Part Integration concept, which is a very large LWB integrating 5 parts into 1, can provide up to 23% weight savings compared to the same reference.

The front module was also reviewed with both cold and hot stamped solutions. Front rails in LWBs are proposed in the third-generation cold stamping grade Fortiform 980, or second PHS generation Ductibor 1000. Both solutions offer good ductility, a low risk of failure, and reach the same weight performance, which is around 16% lighter than a reference in DP780.

The dash panel cross member in DP600 in our reference was also optimised with the following constrains: both crash performance and geometries had to remain similar. Numerical forming simulation highlighted that only Fortiform 980, third-generation steel grade for cold stamping offers enough formability to match the technical constrains and more especially the required formability. Even a switch to DP780 was not possible in our case because of a too low level of formability. This study clearly demonstrated a weight saving potential of 13% offered by the high formability of the third-generation steel grades.

Find out more about ArcelorMittal’s S-in-motion project here