Jaguar Land Rover is concluding its SUV production at Magna Steyr’s Austrian facility in December as part of a strategic shift towards an all-electric brand by 2025. The move includes ending five “zero profit” models to focus on high-margin vehicles and streamline operations.

JLR is taking decisive action to streamline its product lineup, focusing on high-margin vehicles and preparing for an all-electric Jaguar brand by 2025. The carmaker has announced it is ceasing production of five “zero profit” models, so far, including the recently announced Jaguar I-Pace SUV (JLR’s first EV), and Jaguar E-Pace (compact PHEV SUV) models.

The decision comes as part of a much wider reconfiguration of JLR’s manufacturing pivot, which also includes cessation of production for the Jaguar XE (ICE sedan), the Jaguar XF (ICE sedan), and Jaguar F-Type models (ICE luxury sports car). The portfolio rationalisation aligns with JLR’s wider electrification strategy. Production of these models has ended or is scheduled to end as part of the company’s transition to an all-electric lineup, intended to improve profitability and allocate resources to JLR’s most lucrative models, particularly the Range Rover, Range Rover Sport, and Defender, which currently represent over 75% of the company’s order backlog.

How JLR is reconfiguring its manufacturing footprint

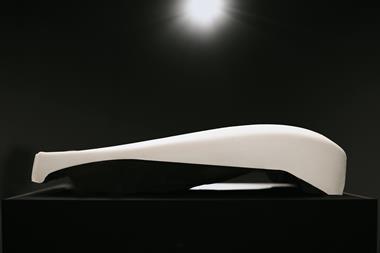

JLR’s current arrangement with contract manufacturer Magna Steyr is ending in December, when Magna’s factory in Austria stops production of the Jaguar I-Pace midsize electric SUV, and E-Pace compact SUV. The end of production for the two models comes as Jaguar pivots from being a “mass premium” brand and adopts a position as an elite lifestyle brand with the launch of three new all-electric models starting in 2025. The first of Jaguar’s new all-electric models will be a four-door GT that JLR’s Chief Creative Officer Gerry McGovern states will have a “jaw-dropping” design like no other electric model on the road today.

The Castle Bromwich plant will cease vehicle production in June 2024 but will expand its stampings operation to produce body panels for all JLR brands. Meanwhile, the Halewood plant in the UK is being prepared for the production of next-generation electric Jaguars.

JLR’s CEO, Adrian Mardell, cited ongoing component supply constraints, particularly semiconductors, as a factor in maintaining limited output of more affordable models. This underscores the importance of supply chain resilience in the company’s strategic planning.

Financial imperatives and implications for contract manufacturers

With a break-even point of 300,000 units annually, JLR is recalibrating its product mix to ensure profitability. The company has indicated that at least one-third of its production needs to be MLA-based (Range Rover or Defender) to meet financial targets.

“JLR’s transformation is emblematic of broader industry trends towards electrification and premium positioning. The company’s first new all-electric model, slated for 2025, will be a four-door GT built on Jaguar’s proprietary JEA platform”

The end of the JLR contract could leave Magna Steyr short of work after it halted production of the Fisker Ocean electric SUV when the American start-up filed for bankruptcy in June. Magna Steyr, owned by Canada’s Magna International, was hit by further bad news in June when Ineos said it was delaying its planned Fusilier electric SUV, which is due to be built in the Graz, Austria, factory.

Magna has been in talks with Chinese manufacturers to replace lost customers. “Over the past 12 months, we have seen very strong activity from all of the Chinese OEMs who are contacting us and who want and need to localize,” Magna Steyr President Roland Prettner said at a media event at the Graz plant in May.

Chinese EV makers are being hit with higher tariffs for EVs exported to the European Union after the European Commission judged they were being unfairly supported by state subsidies. Localizing production of Chinese EVs in the EU at plants such as Magna’s would avoid those additional tariffs, which the EU is likely to make permanent in November. Magna Steyr also produces cars in China for BAIC Group through a joint venture.

Magna Steyr’s Graz factory currently builds the Mercedes G-Class off-roader, BMW Z4 roadster, and the related Toyota Supra coupe. Previous models built at the Graz facility include the Peugeot RCZ Coupe (up to 2015), Mini Countryman and Paceman SUVs (both up to 2016), and Aston Martin Rapide (up to 2012). The plant built 112,217 vehicles in 2022, according to Magna. The factory’s most recent production peak was in 2019, when it produced 168,822 cars.

The road ahead for JLR

Magna began building the E-Pace for JLR in 2017 after JLR was struggling to find capacity in its own plants. The I-Pace started production a year later. JLR has since opened a factory in Nitra, Slovakia, and has shifted to a lower-volume, higher-price strategy. Jaguar stopped production of the XE and XF sedans and F-Type sports cars in May. The brand said it will continue selling stock after the end of production, as well as operating service centers to maintain combustion models.

JLR’s transformation is emblematic of broader industry trends towards electrification and premium positioning. The company’s first new all-electric model, slated for 2025, will be a four-door GT built on Jaguar’s proprietary JEA platform.

This move towards in-house platform development signals JLR’s commitment to controlling key technologies in the electric arena. For automotive manufacturers and suppliers, JLR’s strategic pivot offers valuable insights into the complexities of transitioning to electric vehicle production while maintaining profitability. The importance of flexible manufacturing capabilities and strategic product portfolio decisions cannot be overstated.

No comments yet