High-precision turning specialists and OEM supplier Berger has introduced Tornos’s MultiSwiss lathe technology to its ultra-advanced plant in Ummensdorf

The rise of the Berger Company to become one of the world’s largest enterprises in the field of high-precision turning is closely related to the company Tornos. Both share extremely high quality standards, and Berger is constantly investing in state-of-the-art technology to be able to produce turned parts with maximum quality at reasonable cost. Against this backdrop, it is no surprise that the 200th MultiSwiss could be delivered to the Berger plant in Ummendorf, Germany.

The rise of the Berger Company to become one of the world’s largest enterprises in the field of high-precision turning is closely related to the company Tornos. Both share extremely high quality standards, and Berger is constantly investing in state-of-the-art technology to be able to produce turned parts with maximum quality at reasonable cost. Against this backdrop, it is no surprise that the 200th MultiSwiss could be delivered to the Berger plant in Ummendorf, Germany.

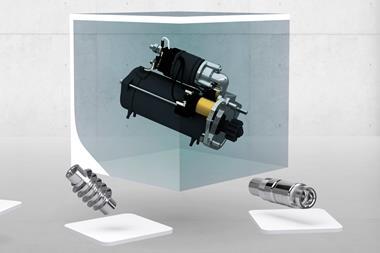

Over the 60 years of its existence, the company that was founded in 1955 by Alois Berger under the name ‘Alois Berger Schrauben und Facondrehteile’ has developed into a global group of companies with almost 2,400 employees and twelve production sites around the world. Today, Berger supplies renowned companies around the globe with complex turned, milled and ground parts of high precision with diameters between 2 and 1,800 mm and a length up to 3m as well as with ready-to-install assemblies. Based on comprehensive know-how, flexibility and commitment, the Berger group has gained international reputation for being a ‘precision expert’, especially in the automobile industry.

Every major car manufacturer is a Berger customer, be it directly or indirectly. Day in, day out, millions of highly complex turned parts made of various metals prove their worth, eg. in diesel fuel injectors, ABS and ARS systems, carburetors or valves. The Berger Holding sees potential new markets especially in the fields of camshaft phasing and direct fuel injection. With this in mind, the Ummendorf site has been significantly expanded –5,000 sq.m. of floor space has been added to the base area.

The new, ultra-advanced plant was opened in 2015 and now covers 12,000 sq.m. This investment is proof of Berger’s foresight. Even if the company does not expect a major volume growth in Europe, it continues investing in technical development processes in Germany in order to subsequently transfer the steady processes to its plants in North America and China.

Extreme demands, extreme solutions“Nowadays, we cannot sell capacity but only solutions,” this statement by Herbert Maurer underlines the ambition of the company. In 2015, relying upon its own expertise and capability, the company applied for the supply of a leading OEM with the OEM’s global demand for a key component of an advanced direct fuel injection system. The volume amounted to 16 million parts. Herbert Maurer recalls that the requirements were and are still fierce. Since the workpiece is installed directly in the combustion chamber, it is made of a high-strength material.

The complex geometries have to be machined with an accuracy tolerance not exceeding 2 μm. Roger Sachse, Managing Director at Tornos Technologies Deutschland, adds: “When being asked to rate the degree of difficulty on a scale from one to ten, I would say ten plus.”

The contract award process took several months and comprised nearly 20 different designs. The specific challenge for the Berger team was to make the machining process suitable for series production. “Even if the production of a couple of workpieces with the required quality is ambitious, it is not too difficult,” Herbert Maurer says. “But to economically produce 16 million parts through 5-axis machining with tight test intervals, that’s the real thrill.”

Acid test for the systemIn the run-up, Berger considered various Tornos machines and other competitive products to find the appropriate manufacturing strategy. The company’s target was to find the optimum start from a huge matrix. The new MultiSwiss soon turned out to be the best means of production. “At the moment, it is simply the most precise lathe and, it seemed to be the most appropriate machine to achieve stable processes,” Herbert Maurer explains. Nevertheless, it took almost an entire year to get the process ready to run to the utmost satisfaction of the customer.

As far as possible, the technology development took place at Berger, in close cooperation with the Tornos engineers. In the course of this project, the cooperative partnership that had developed over the previous years took full effect and series production could be started six months earlier than initially scheduled.Instead of experimenting on a sole machine, Berger purchased ten MultiSwiss machines and has optimised the processes from the very beginning with series production in mind. “To us, it was important that the results were scalable.

Already in the test phase, we have compiled a comprehensive data pool that helped us to correctlyclassify the effects of the individual parameters on the overall process.”

The ten MultiSwiss machines are now running 24/7 and fully meet the expectations of the persons in charge. The original intention was to split the volume and to have the portions produced in the plants in Germany, North America and China. But in view of the extremely positive start-up phase in Ummendorf, the capacities of the US and Chinese plants can be utilised this year.

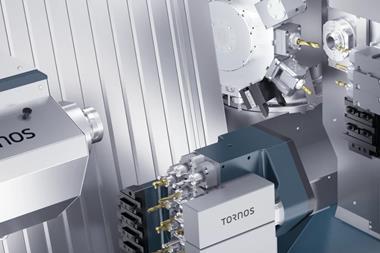

A masterpiece of technologyWith the development of the new MultiSwiss, Tornos scored a big hit and already the 200th machine of this type had been delivered. All MultiSwiss machines are equipped with independent, mobile spindles that are supported by hydrostatic bearings. The Z-axis enables workpiece lengths to be machined that are difficult to realize on conventional multispindle lathes. At each machining position, the speed and the machining conditions can be exactly set. The operator literally ‘enters the machine’ and can conveniently change the tool holders without having to lean intothe machine.

With its most easy access, this ergonomic working area, which is larger than on any other machine, it offers substantial economic advantages when changing the batch. Thanks to this concept, the MultiSwiss can be set up just as conveniently as a single-spindle lathe. The sole difference is the number of collets that have to be replaced. Furthermore, chip removal is outstanding. Each spindle has its own C axis. The hydrostatic bearing technology provides excellent damping characteristics that enhance surface finish and increase tool life, especially when machining tough materials. The productivity is always of utmost importance for multispindle lathes because every second counts. The torque-motor technology enables indexing times of 0.4 seconds and therefore ideally correlates with this pursuit of efficiency.

Optional equipment such as oil mist extractor, chip conveyor, fire extinguishing system and a high-pressure pump are all harmoniously embedded in the machine. This integration provides a small footprint that means a MultiSwiss machine will find its place in every workshop. Thanks to peripheral system management, the machine is extremely compact. The new Berger workshop in Ummendorf has space for further machines, so the Berger/Tornos success story can continue.