Ford is downsizing the capacity and investment in its planned EV plant in Marshall, Michigan, following suit of GM scrapping its EV production targets.

Ford’s plant is set to make lithium iron phosphate (LFP) batteries for its EVs from 2026 by using technology licensed from Chinese battery maker CATL. It was originally planned to have an output of 35 GWh annually, making enough battery cells for 400,000 EVs annually, but will now have its capacity cut to 20 GWh per year, to power roughly 230,000 EVs. Once complete, 1,700 staff will be hired, compared to the previously planned 2,500 employees.

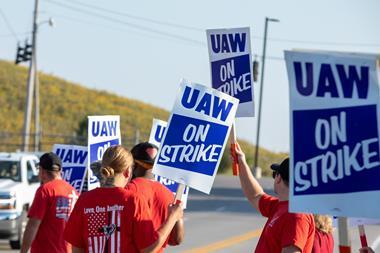

During the recent United Auto Workers (UAW) strikes on the Detroit ‘big three’, Ford paused construction on its $3.5 billion Michigan battery plant due to concerns about its ability to competitively operate the plant while negotiations were ongoing. In September, the carmaker said it hadn’t “made any final decision about the planned investment there”. Following its deal with the union being ratified this month, Ford said construction will restart and, despite downsizing, the carmaker still expects battery cell production to begin in 2026.

The investment was originally announced in February this year as part of the OEM’s plan to localise EV battery production in the US.

In a statement, Ford said: “While we remain bullish on our long-term strategy for EVs, we are re-timing and resizing some investments. As stated previously, we have been evaluating Blue Oval Battery Park Michigan in Marshall. We are pleased to confirm we are moving ahead with the Marshall project, consistent with the Ford+ plan for growth and value creation. However, we are right-sizing as we balance investment, growth and profitability.”

It added: “We still expect Blue Oval Battery Park Michigan to be the first of Ford’s battery plants of this kind when it begins producing LFP battery cells starting in 2026.”

Ford follows the suit of GM, which announced last month that it would be abandoning its target to produce 400,000 EVs by the end of 2024. In its third-quarter financial results, Mary Barra, CEO, GM said the OEM was taking “immediate steps to enhance the profitability of [its] EV portfolio and adjust to slowing near-term growth”.

Paul Jacobson, chief financial officer, GM added that the OEM would not be providing new targets, but instead would move to “a more agile approach to continually evaluate EV demand and adjust production schedules to maximise profitability”. He said: “We purposely built flexibility into our manufacturing facilities and are uniquely positioned among our competitors to be able to flex our production between ICE and EVs.”

Paul Stephens, Manufacturing Transformation Lead for Ford Motor Company spoke to AMS about the demand for EVs and lessons that can be taken from existing plants to new EV production facilities.

He said that developing new vehicle platforms at the likes of Ford’s Blue Oval City site with SK Innovation in parallel with the plants brings opportunities for further alignment.

Watch his interview at AMS Automotive Evolution Summit 2023 here.

No comments yet