E-mobility has truly opened the door to a host of new faces to the automotive industry, outliers who have approached the EV challenge with a different viewpoint, delivering innovative solutions for vehicle architectures, powertrains and batteries. Some of these are familiar and broad in their scope, others are far less obvious, very niche but no less important or innovative.

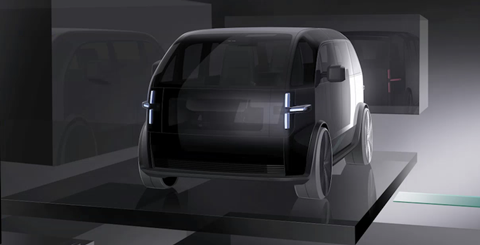

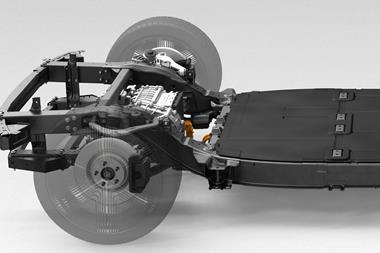

AMS Digital: e-mobility 2020 presents our latest focus on the world of electric vehicles, taking a closer look at some of these outliers, concepts and solutions offered in the e-mobility vision. California-based Canoo impressed us here at AMS with its production ready, campervan styled body-in-white and highly engineered, low-profile skateboard chassis. The company’s different approach to e-mobility, with a subscription-based service to customers and a highly modular chassis and body concept, has also been realised in its manufacturing strategy. Behind all of this is a team of very experienced automotive industry experts who have applied solid production techniques and an understanding of materials and structures to turn the design into an uncompromised reality.

After successfully reimaging the iconic London black cab into a fully electric, light-weight aluminium bodied vehicle, fit for modern urban transport, LEVC has turned its attention to LCVs using the expertise gained with the TX5 taxi to create the VN5 van. AMS gained an inside view of the production operation at the company’s Ansty, UK, factory and our Q&A with Mofid Elkemiri, LEVC’s manufacturing operations and quality director.

Behind all of this is a team of very experienced automotive industry experts who have applied solid production techniques and an understanding of materials and structures to turn the design into an uncompromised reality.

New vehicles aside, batteries continue to be the focus of a great deal of R&D and investment. Much of this development is hidden inside the pack, so we have lifted the lid on the battery chemistry, revealing nano technologies that could speed up charging times and increase the durability of the cells, also specialist coatings to improve thermal performance and safety.

Another outside challenger takes the form of the aluminium-air (Al-air) fuel cell. In this instance offering an alternative to the dominant Lithium-ion technology. The original Al-air cell was developed back in the 1960s but has been updated with a new, non-toxic electrolyte and makes a strong case in terms of vehicle range and recyclability.

All these outliers are set to become the ‘new’ mainstream of EV production and technology, but right now all automotive manufacturers are facing their biggest challenge; the impact of the Covid-19 pandemic. When markets return to somewhere near normal levels OEMs are very likely to review their respective EV programmes and refocus on only the most profitable segments and cost-effective technologies, and we should expect to see a few new faces in the EV line-up.

No comments yet