Virtual production networks provide automotive manufacturing with myriad solutions like advanced time- and cost-saving simulations, global collaboration capabilities, and innovative tools like digital twins to harness untapped production flexibility.

Automotive manufacturing is witnessing a sea-change due mainly to the convergence of formerly distinct technologies into powerful new synergies. Some of these include innovations such as 3d printing (an outcome of Computer-Aided Design meeting Robotics); extremely enhanced vehicle surface inspection, (a product of machine vision technology meeting Artificial Intelligence); or more recent, and still budding, paintshop innovations, (the result of automation fusing with ink-jet technologies).

At the very same time, there is the unstoppable quickening towards increasingly digitalised production systems, such as can be seen at BMW’s Munich plant, or with JLR’s cloud-based global production network, and the veritable capstone of digital production, can be found in what has come to be known as the ‘virtual production network.’

The potential of this technological approach to solve numerous production challenges, ranging from achieving widespread cost efficiencies and addressing performance issues, to enabling extended production collaborations and fostering flexibility - as well as untapped production creativity - is unmatched. And it’s no surprise that some robotics companies are, as primary automotive tier-suppliers, at the forefront of many of these innovations.

Digital twin technology for vehicle production and training

As virtual replicas of physical automotive manufacturing processes, assembly lines and entire production systems, digital twins use real-time data from sensors and other sources to mirror the actual performance and behaviour of the physical process. This allows manufacturers to optimise vehicle production workflows, predict maintenance needs, identify bottlenecks and test changes virtually before ever having to implement them in the real world. The benefits of this are far-reaching.

In the case of JLR, the carmaker says that in the drive towards electrification, 95% of its global retail partner technician workforce is now necessarily EV trained, with a further 11,000 of its manufacturing colleagues currently being trained to build BEVs. But such training costs money, precious production time, and space.

Virtual production technologies are able to offer solutions to many of these issues, including providing training environments that are free from the potential injuries associated with training in industrial facilities.

Porsche’s management and IT consultancy, MHP, for example, are using metaverse technologies to solve these upskilling issues. During a recent showcase event, the company implemented a sector of the Zuffenhausen plant’s production process as a highly-realistic 3D training module using the Apple Vision Pro.

![MHP_Media_Shopfloor_Training_Apple_Vision_Pro_04[4]](https://d2oevnekjqgao9.cloudfront.net/Pictures/480xAny/6/1/6/321616_mhp_media_shopfloor_training_apple_vision_pro_044_588957.jpg)

MHP is essentially utilising the spatial computing capabilities of the Apple Vision Pro to provide immersive, hands-on training for complex automotive manufacturing processes like engine assembly.

“In the production step that we showcased, the worker learned how to collaborate with a virtual robot on a welding station,” says Guy Williamson, CEO of MHP Consulting, UK. “They started the process with a button, took a mechanical part from a box and placed it precisely on a welding table.”

“At a time where labour shortages and skills gaps are a growing concern, modern technology will be a key to success”

- Guy Williamson, CEO of MHP Consulting, UK

The trainee then used the precise eye-tracking of the Apple Vision Pro to navigate through the user interface and instruction menu, and there were no controllers needed - it was a hands-free experience. “The hand-tracking,” says Williamson, “was then used to take virtual parts from a box and place them on the welding table.” The Apple Vision Pro can detect the position of the trainee and visualise conflicts to virtual barriers in order to remain safe while using the equipment. “In our case, the distance to the moving robot was a key safety consideration,” says Williamson.

Such an example is, in many ways, one of a complete virtual training environment. With Apple’s new API’s, MHP could also overlay physical objects with virtual objects in their new training scenarios.

“At a time where labour shortages and skills gaps are a growing concern,” says Williamson, “modern technology will be a key to success.” And there is yet another boon to virtual production networks in the modern era. “We see gamification within the training applications as a gateway to making the learning journey even more appealing - especially for the younger generation,” he concludes.

Simulating virtual production cells for enhanced flexibility

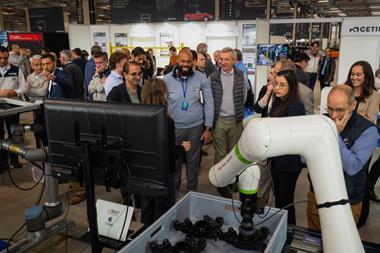

I recently had the opportunity to visit ABB’s Robotics Centre in Friedberg to experience their own virtual production network. ABB also utilises VR glasses (or goggles), and digital twins to help their clients transform automotive manufacturing processes.

The demonstration began with an introduction to ABB’s proprietary software. Within the software, ABB develops new simulation cells for reachability studies, cycle time, and collision studies. It also allows the robotics giant to simulate entire production cells, including that of material flow. “The cell you see behind us is a real production cell replicated in our very own, proprietary software,” said Martin Volk, Manager, ABB Technology Center. “With VR glasses, you can step into the cell virtually.”

Donning the high-spec specs, I did just that, and was cautioned by Joerg Rommelfanger, Head of Robotics Division Germany & Head of Local Business Line Automotive, to be mindful of the virtual robot’s movements. The quip landed instantly. He further highlighted the collaborative potential of such virtual production technology for automotive. “By bringing this software to the cloud, we can enable seamless collaboration,” he said. ”Teams can work together, regardless of their location, whether in China, the US, or Germany.” This capability for global collaboration allows internationally dispersed teams to optimise workflows and make critical decisions in real-time, overcoming the limitations of geographical boundaries.

“Advancements in computational power have made these simulations increasingly accurate and practical”

Rommelfanger added that customers can easily design and adjust elements in the virtual environment. If a customer prefers an operator panel in a different location, for example, it can easily be moved during the design phase. “This level of flexibility is lost during the physical installation phase,” he said. Although not 100% identical “twins”, the virtual is swiftly reflecting the physical environment with increasing accuracy. Advancements in computational power have made such simulations increasingly accurate and practical; with the goal of eventually rendering them identical enough, that they reflect the physics of the actual production world.

Expanding the virtual production real estate

But while companies like Porsche, MHP and ABB are using face-mounted ‘glasses’ to simulate virtual automotive production networks, there are other developments in the space which are expanding on the digital twin itself. KUKA’s ‘Dome’ is a totally immersive virtual representation digital twin; a room into which you step, as if occupying the physical production space itself, with the rendered simulations projected onto the surface around you. No goggles needed.

Florian Klauke, KUKA, says, “the KUKA Dome, or rather the engine behind it, gives us the opportunity to walk through the plant in 3D at a very early stage of the project. We have developed a high-performance environment that enables us to walk through the plant in a 1:1 ratio and analyse and discuss every single process, and the ramifications are manifold.

“First and foremost, we save an incredible amount of time right from the start of a project,” he says. ”We create a common understanding of our solution right at the outset. In addition, we eliminate issues in the production layout that we previously could only discover on the physical production site - space conditions in particular are often misjudged in the 2D layout, and the (very costly) effects are only noticed later.

“What we at KUKA regularly experience with our customers,” he continues, ”is that we are able to introduce production innovations again and again. The ability to simulate A/B comparisons directly next to each other often leads to eye-opening moments, while at the same time increases the understanding of the added value of great engineering work.”

“The most agile automotive production companies win the game”

- Roland Ritter, Portfolio Manager Simulation, KUKA Deutschland

Klauke points out that with the automotive manufacturing world becoming increasingly complex and volatile, the virtual factory layouts enable all participants to communicate in a complex - yet optimal landscape, “allowing for new Ideas to be explored with minimal effort, facilitating all to gain valuable insights into tomorrow’s production processes.

“This increases confidence in the manufacturing solution at much earlier phases, and reduces the actual commissioning time, failure rate, and troubleshooting once it is set up,” he says.

Roland Ritter, Portfolio Manager Simulation, KUKA Deutschland, adds, “in our volatile times, production usually isn’t constant. We need to be able to scale the volume up and down as required, to quickly shift over to other products (such as from EVs to ICEs), to swiftly adapt to demand.

“The most agile automotive production companies win the game,” says Ritter. ”Traditionally, changing over would mean we’d have to cease robot operations to change fixtures, grippers, equipment etc. But stopping production costs money for every second of cessation; and so we want to shorten that time as much as reasonably possible. This means we want to prepare everything offline while the robot is still running, then stop and deploy all prepared work. The less we have to do physically on site, the better - and the less money we burn by not running equipment.”

Ritter also comments on the advantages of virtual production on material flow. He points out that on a linear production line, companies don’t want to have a bottleneck anywhere, since “the weakest link in the chain defines the overall output.” He says that putting the limiting elements into overdrive, will result in earlier failures, and greater wear and tear leading to increased maintenance on the material.

“So this we need to know in advance, and plan accordingly to utilise the money spent in the best possible way. And this is just thinking linearly - if we have modern matrix production systems with agile adaptations to material flow and Just in Time (JIT) material delivery, capacity planning would be unthinkable without accurate digital twins.”

Topics

- ABB

- Additive/3D Printing

- Artificial intelligence

- Assembly

- Automation

- Automation and Digitalisation

- BMW

- Bodyshop

- Digital Twin

- Digitalisation

- Factory Transformation

- Industry 4 and Smart Factory

- JLR

- Kaizen

- Logistics

- Manufacturing engineering

- OEMs

- Operational Excellence

- Paintshop

- Plant Functions

- Porsche

- Press and stamping

- Process Improvement

- Regions

- Robotics

- Smart Factory

- Suppliers

- Sustainable production

- Sustainable strategies

- Systems

- Virtual reality

- VR and AR Systems

No comments yet