Megacasting: a chance to rethink body manufacturing

By Götz Fuchslocher2022-02-10T05:31:00

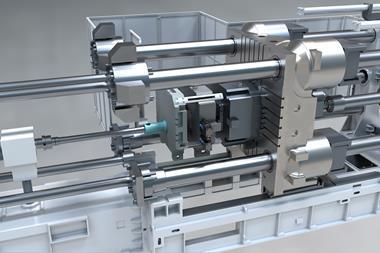

The aluminium die-casting process could revolutionise body construction. Professor Wolfram Volk, the department head for forming technology and casting at the Technical University of Munich, explains the advantages and disadvantages of so-called ‘mega’- or ‘gigacasting’.

Several vehicle manufacturers are ramping up investment in the use of megacasting as they build new plants and revamp others for electric vehicle production. While Tesla has been a frontrunner, using the process to cast large body structures that are reported to save 70 parts for each large piece, Volvo Cars has also just announced a plan to switch to aluminium megacasting for rear body structures starting at its Torslanda plant in Gothenburg, Sweden for new electric vehicle platforms starting in 2025.