The coveted “Factory of the Year” award has gone to Regensburg in the category of large-series assembly. The plant was lauded for its remarkable flexibility, workforce dynamism, and cutting-edge digital innovation, further solidifying its place as a leader in automotive production.

BMW Group’s vehicle plant in Regensburg has earned the title of “Factory of the Year” for 2024 in the highly regarded category of “excellent large-series assembly.” This recognition places the facility among the elite in German industry, demonstrating its adaptability in an era defined by rapid technological shifts and escalating customer demands.

Regensburg, one of more than 30 production sites within the company’s global network, rolls out up to 1,400 BMW X1 and X2 models each day. These vehicles, which are sent to customers worldwide, represent an impressive feat of engineering efficiency and flexibility. On a single production line, the plant manufactures models with a variety of powertrains, including internal combustion engines, plug-in hybrids, and fully electric vehicles. This capability to seamlessly shift between different drive technologies is one of the key factors behind its recognition.

Süddeutscher Verlag and Produktion steer “Factory of the Year”

The “Factory of the Year” competition, now in its 33rd iteration, is orchestrated by management consultancy Kearney in collaboration with AMS’ parent-company Süddeutscher Verlag, as well as its sister-company Produktion. It remains one of Germany’s most prestigious industrial accolades, celebrating manufacturing facilities that excel in meeting the evolving challenges of the modern production landscape.

The judging panel highlighted the flexibility of BMW Regensburg, both in terms of its physical infrastructure and its workforce. “The innovative strength and dynamism with which the Regensburg plant is implementing the transformation to iFactory together with the entire workforce is impressive,” said Daniel Stengel, director at Kearney and project manager for the competition. He further noted that the plant’s flexibility served as an inspiration for the future of manufacturing in Germany.

A skilled and dedicated team powers Regensburg

The leadership at Regensburg attributes this success to its highly skilled and dedicated team. Armin Ebner, head of BMW Group Plant Regensburg, reflected on the achievement, remarking, “BMW Group Plant Regensburg is in an exceptionally strong position – thanks to our highly professional, motivated team. Being named ‘Factory of the Year’ by an independent panel of expert judges is both a significant achievement and a source of motivation for us.”

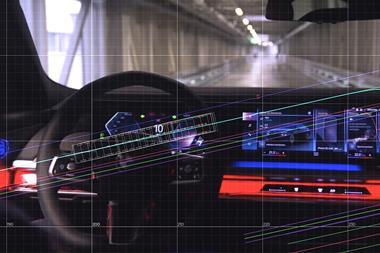

Ebner extended his gratitude to the plant’s workforce, acknowledging their collective effort, flexibility, and commitment to quality. Beyond its workforce, the Regensburg plant has been an early adopter of advanced digital tools, including artificial intelligence (AI), which has been instrumental in boosting productivity, quality control, and operational resilience.

This digital-first approach ensures that the plant remains at the forefront of automotive manufacturing innovation, ready to meet the demands of an increasingly complex industry.

Identifying true excellence in automotive production

The rigorous selection process for the “Factory of the Year” title is designed to identify true operational excellence. The competition’s two-stage evaluation process first involves the submission of an application with key performance data. Shortlisted companies then undergo an in-depth audit by Kearney experts. Winners are chosen by a panel of industry and academic professionals, all of whom possess deep insights into the nuances of manufacturing success.

The formal recognition ceremony for this prestigious title is set to take place during the “Factory of the Year” congress in the spring of 2025. For the BMW Group and its Regensburg facility, this accolade not only recognises past achievements but also sets the stage for continued leadership in a rapidly transforming industry.

No comments yet