Automation – Page 237

-

Article

ArticleHigh-temp inert atmosphere oven

The 966 is an electrically-heated, inert atmosphere oven that Grieve says is suitable for stress relief of machined steel. Workspace dimensions of this oven measure 24” W x 36” D x 24” H. It features 18KW Incoloy-sheathed tubular elements to heat the oven chamber, while a 1000 ...

-

Article

ArticleNew CNC machine control system

Yamazaki Mazak has launched its Smooth Technology, which incorporates the new Mazatrol Smoothx CNC alongside new machine hardware and servo systems. The company says this will deliver an improved operator experience, faster machining times and further integration of CNC into the overall factory management system. The company claims the ...

-

Article

ArticleInterview: Atterby and Burton at Luxus

Peter Atterby, managing director, and Terry Burton, technical manager, discuss Luxus' commercialisation of a new range of lightweight polypropylene polymers for interior trim, featuring up to 60% recycled contentJoanne Perry (JP): Luxus has been supplying thermoplastic materials to the automotive industry for 30 years. Which of today’s models feature Luxus ...

-

Article

ArticleJLR starts building £150m innovation centre

UK – The 33,000 sq. m facility, located at the University of Warwick, will become a hub for advanced research, equipped with the latest workshops, laboratories, virtual engineering suites and powertrain capabilities. A wide range of design, visualisation and prototyping activities will take place at the centre.The development of the ...

-

Article

ArticleFord hits 5m mark for EcoBoost

US – The milestone, 1.0-litre unit rolled off the assembly line at Michigan Assembly Plant, less than three years after the 500,000th engine was made. The 5 millionth EcoBoost was installed in a Ford Focus.Production of the 5 millionth EcoBoost coincides with the first full year in which this type ...

-

Article

ArticleThe new EMC: Jaguar's genie?

The OEM's Engine Manufacturing Centre at Wolverhampton could grant its wish to make 1m cars per yearJaguar is now making its own engines for the first time since the mid-1990s, when the AJ6, AJ16 and V12 went into retirement. A new £500m facility, in what was once the heartland of ...

-

Article

Article- 捷豹的精灵?

在Wolverhamptom的一个新的发动机制造中心,有可能帮助达成JLR年产100万的愿望捷豹公司现在自己制造发动机,这是自20世纪90年代,AJ6、AJ16以及V12开始停产以来的第一次。一个斥资5亿英镑的工厂(这里曾经是英国机械工程与汽车生产的中心)开始为捷豹紧凑型XE轿车,以及其姊妹公司-路虎的Discovery Sport制造Ingenium柴油机。汽油发动机将于2016年6月开始生产。 Ingenium只是公司第4个公司内发动机。其模块化的全铝质2.0升发动机最终将代替4缸福特柴油机,而用于所有JLR车型上。但是,与福特之间的联系并没有断绝。美国福特在英国Bridgend(汽油机)和Dagenham(柴油机)的工厂,将继续为JLR提供V6和V8发动机。 “ingenium”来自拉丁语,是“天赋”的意思,据说会展示该发动机的性能。这是一个全新的概念,轻量而高效:该柴油机有2个功率输出,这么低的功率输出能让XE轿车的二氧化碳排放低于100克/每千米。两个版本都满足EU6的排放规定。 如果说Ingeniun是最先进的话,Wolverhamptn的发动机中心也是体现尖端科技,这里离捷豹Castle Bromwich工厂和索利哈尔的路虎工厂(这里即将推出XE)只有30分钟的车程。向北2个小时就达到路虎在哈利伍德的另一个工厂,那里将生产Discovery Sport汽车。新的发动机,新的工厂计划始于4年前,2012年开始建造和装配,此时也是运营总监Trevor Leek进入公司的时候。他说,“我们的目的是转变制造发动机的方式,让它成为全球精工的新标志 — 不仅是我们的技术方案,还有我们投入的人才。” 工厂所在地区的失业率高于平均水平,那里有很多谋职的技术工程师。但是Leeks说,那里也有很多人并没有从事工程的背景,包括一些退役军事人员;他们的能力和态度优于经验。等到工厂全力运转时,将会产生1,400个工作岗位,并在供应链上还会有5,500个岗位。 工厂占地100,000平方米,位于过去的一个工业场地,在他们到来之前处于棕色地带。工程维修部高级经理Neil Hume说,“在我们到来之前,你只能看到一些遛狗的人。”南斯塔福德郡地方政府和伍尔弗汉普顿政府已经建设一些基础设施,用以支持JLR工厂。 工厂由3个主楼构成:机械加工车间,柴油机装配车间与汽油机装配车间,后者目前还在装配阶段。这里的工人大约有600人。机械加工车间的灵活性员工中只有60人在38,000平方米的机械加工大厅里工作,主要从事维修、清洁与改进业务。真正的机械加工是由173个尖端机械(工厂在这方面投资1.5亿英镑)来完成的。Leeks指着94 MAG 5轴数控机床说,“这些机械之所以是尖端,是因为他们的灵活性。从理论来说是可以进行工具更换的,也就是说在一个周末,我们就可以将滑轮绳索的开端部分转到首缆的末端。“曲轴生产线上的误差在3微米以内。人的头发是50微米粗” – Neil Hume, JLR工厂里的这个部分只进行3种制造:机械制造气缸体、气缸盖和机轴。Ingenium柴油机所需剩下的243个组件都来自厂外供应商,以准时化供应直接到达装配大厅。没加工的缸体是由德国萨尔州的Nemak工厂提供;该公司还从捷克共和国供应气缸盖铸件;锻钢曲轴来自西班牙的CIE工厂。缸体和缸盖的生产线以U型布置,通过Liebherr构架和Bleichert传送带,从一端传送进行下一个操作,但是曲轴是由26个构架轮班安装。 供应商的名单看上去就像一个机床制造商联合国,但是有很多业务也都是有英国公司提供的。其中有:Harry Major(洗涤机械),TKSE(装配机),EWAB(传送带),JW Froehlich(气门座、装配指南和泄漏试验机械),Neuteq(轴颈抛光),还有研磨机制造商泰斗Landis公司。德国也做得很好;除了MAG机械单元之外,该厂还是Kuka机器人,所有的操控系统都来自Siemens公司。机械比人多气缸体生产线上总共有78台机器,包括57个MAG CNC单元,但员工只有14人。缸体首先要加热到180°C,这样才能插入铸铁气缸套,然否冷却到室温 — 这样的一个工序需要大约35分钟。 缸体在完成之前要经过23种不同的操作,包括在MAG单元里的5个阶段。在这个期间,缸体要走过570米厂的路程,经过削减加工只剩到35公斤重。在不同的阶段,有些组件要被拿出来计量 — 这是一系列质量管理检测的第一步 — 每50个发动机中就会拿出一个来检测尺寸。这些发动机被送到一个单独的房间,进行更为严禁的检查。期间要清洗切屑,因为这是在使用高质量铝来制造,而且很可能在以后出现在另一个Ingenium发动机里,或者甚至是铝车身的Jaguar XJ或Range Rover汽车里。 气缸盖生产线上最终会生产两种不同的衍生产品:一个用于柴油机,一个用于汽油机。这里有46个机器,其中的32个在MAG CNC单元里,还有12名员工。气缸盖在各种操作之间稍作循环 — 375米 — 然后就只剩下15公斤重了。Hume说,“我们必须在一次操作上完成所有的机械制造。这里主要由4个机械操作,然后进行装配,并在300bar的压力下进行清洗。” 曲轴生产线上拥有46个机器人,包括Niles Simmons公司的车床、铣床和磨床。其中的一个就能从没加工原件上削下2公斤的重量。Landis磨床的工作原理与Maglev 铁路是一样的,都是利用磁电机和静压导轨来减少摩擦,实现更高的旋转研磨速度和精确度。JLR新工厂的重要性发动机制造中心(EMC)对捷豹路虎(JLR)公司的可持续性而言,不论从环境角度还是商业立场上都非常关键。一方面,21,000光伏屋顶电池能提供30%的工厂能源消耗,每年减少2,400吨的二氧化碳排放,而且工厂收集雨水进行再利用,还有一个野生动物廊道用于保护当地物种。 另一方面,工厂在满功率状态下,每年能为JLR汽车厂提供500,000个发动机 — 如果公司能够完成每年生产100万辆汽车的中期目标的话,就会用掉上面一半数量的发动机。 营运总监Trevor Leeks说,“这是我们第一次自己生产发动机。Ingenium将会使用在许多系列的汽车,而且我们还将在中国生产,专门为中国市场服务。我相信,将来我们还要在集团内参与另一种动力系统战略。我们的灵活性足以应付这一切。”最后的研磨是由一个外表面镶有人造钻石的轮子完成的,它每秒钟速度是90米。外表面可以研磨80,000个零部件,但是每完成80次操作就需要重新整理。在最后研磨之前,要使用一种感应加热工艺在曲轴承重表面铺上一层硬皮,以提高耐磨性。Hume说,“我们购买了行业里最好的机器。在极轴生产线上,我们的误差在3微米以内。人类的头发是50微米粗。” 每个气缸体、气缸盖和曲轴的生产都会花费4个小时左右,如果机械加工车间满负荷运转,可以每38秒钟就完成一个组件。 发动机的装配需要200个操作,涵盖16个生产线区域,一个组件区(是第17个),气缸盖在这里汇集,然后被送到主体生产系统里。有一个小型组件仓库,修复供应链里所有的问题,包括糟糕的天气和交通。但是强调准时化交付是工厂“精益高效”政策之一。一共有71家供应商,其中的30%是英国公司。 这里同样也有尖端机器,尤其是J ...

-

Article

ArticleWilliams hires new technical director

UK – Joining the engineering services and technology division of the group, Paul McNamara will report to Craig Wilson, managing director of Williams Advanced Engineering. He will be responsible for the overall technical management and delivery of an expanding range of projects in automotive and motorsports, plus energy, defence and ...

-

Article

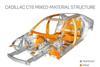

ArticleCadillac reveals details of CT6 materials

US – While the structure of the sedan is aluminium intensive, a total of 13 materials have been customised for different areas of the car. The materials mix for the CT6, which goes into production later this year at GM Detroit-Hamtramck, Michigan, requires multiple joining methods including spot welds, flow ...

-

-

-

Webinar

WebinarThe value of co-engineering for ArcelorMittal automotive customers

How can co-engineering with ArcelorMittal help carmakers to achieve their weight, cost and safety targets with steel?Are you involved in the design and manufacture of cars? Do you design car bodies or closures and need to save weight while improving safety at an affordable cost? Then you surely know that ...

-

Article

ArticleZipse to replace Krüger on BMW board

Germany – Effective from the OEM’s annual general meeting on May 13, 2015, Oliver Zipse will become board of management member for Production, while Krüger becomes chairman.Zipse started his career with BMW in 1991 as a trainee, moving up the ranks to hold a variety of management positions. He is ...

-

Article

ArticleRenault invests $100m at Santa Isabela

Argentina – The investment at the 60-year-old plant will enable the introduction of a new vehicle platform and equipment to make the Renault Logan, Sandero and Sandero Stepway. It will also go towards the development of a local supplier network.Beginning in March and continuing over 20 months, the OEM will ...

-

Article

ArticleControl quality – visit the 2015 show

This year's 29th Control international fair will exhibit services and products relevant to auto engineeringThe Control international fair has always felt less overtly commercial, and more academic and scientific in tone compared with other major engineering trade shows. Yet nobody involved in the event could fail to recognise the impact ...

-

Article

ArticleZanlunghi to lead Jeep in EMEA

UK – Taking on responsibility for all sales, marketing, product and network development operations for the brand within Europe, the Middle East and Africa, Steve Zanlunghi replaces Chris Ellis, who will assume new duties within Fiat Chrysler Automobiles (FCA).Zanlunghi will continue in his current role of managing director, FCA UK, ...

-

Article

ArticleÉ o lugar para se estar

Com uma "indústria integrada" o tema da Hannover Messe 2015 show promoverá desenvolvimento da indústria 4.0.Com a missão de mostrar desenvolvimentos e inovações em toda a cadeia de valor industrial, o Hannover International Show tem sido a maior feira de negócios para aqueles relacionados com a engenharia. Para o setor ...

-

Article

ArticleDefendendo uma herança orgulhosa

Produção de Land Rover 4×4 originais acabará em grande estilo, acompanhado por uma linha comemorativa Celebration 1940 que mostra as técnicas de fabricação; AMS deu uma olhadaOs fabricantes de automóveis trilham uma linha tênue ao desenhar sua história. Se eles evocam o passado muito serão acusados de serem "retrô" e ...

-

Article

ArticleVW celebrates big ‘Bulli’ birthday

Germany – Production of the Transporter began 65 years ago at Wolfsburg, then at Hanover from 1956. A total of 11m T-series vehicles have now been made worldwide, and the new-generation model, the T6, will launch later this year.Inspired by a simple flat-bed vehicle he saw at a VW plant, ...

-

Article

ArticleUna visita ineludible

La feria Hannover Messe 2015 promocionará los desarrollos de la industria 4.0 con el tema central ‘industria integrada’ La Feria internacional de Hannover siempre ha tenido el objetivo de mostrar los desarrollos e innovaciones en toda la cadena de valor industrial y es una de las mayores ferias ...