The webinar will explore some examples of best-in-class steel grades for chassis applications and cover ArcelorMittal’s S-in motion® Chassis study which identifies potential savings in mass of up to 20%. As part of the study, specific assessments have been conducted on formability, weldability, and fatigue. The study also considered ArcelorMittal’s AHSS grades including ferro-bainitic, complex phase, and press hardenable steels and the potential to optimise the balance between weight, performance, and affordable cost.

The presenters:

This webinar is presented by Ahmed Belhadj and Elie Gibeau from ArcelorMittal’s Global R&D team.

Research engineer Elie Gibeau has worked for ArcelorMittal Global R&D for seven years. He specialises in the development of automotive steel solutions. Elie is an expert in ArcelorMittal’s steel grades for chassis applications including control arms and subframes.

Research engineer Elie Gibeau has worked for ArcelorMittal Global R&D for seven years. He specialises in the development of automotive steel solutions. Elie is an expert in ArcelorMittal’s steel grades for chassis applications including control arms and subframes.

Ahmed Belhadj has worked in automotive product development for ArcelorMittal Global R&D for 13 years. As the new-product manager, he is in charge of the development and promotion of coatings as well as cold-rolled complex phase, dual phase, and martensitic grades. Ahmed is also in charge of AHSS hot rolled products such dual phase, ferrite bainitic, and complex phase steels.

About ArcelorMittal

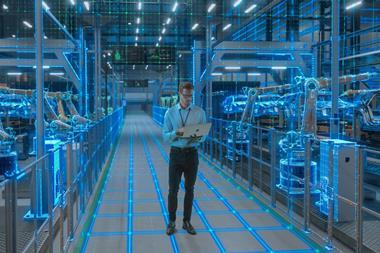

ArcelorMittal is the world’s leading steel and mining company. It is the leading supplier of quality steel products in all major markets including automotive. ArcelorMittal is present in more than 60 countries and has an industrial footprint in over 20 countries. ArcelorMittal develops automotive steel products and solutions to optimise the weight and cost of vehicles and reduce carbon emissions while ensuring high standards of safety.

For more information visit automotive.arcelormittal.com