Conference chairman Simon Duval Smith outlines the expert OEM and tier supplier speakers contributing to the agenda of this must-attend event.

Bringing together senior manufacturing and purchasing executives from OEMs and tier one suppliers, the North America AMS conference is returning to the US on September 23-24 at the MGM Grand Hotel, in Detroit. Along with presentations from equipment and service providers, senior OEM executives will outline their strategies to boost production and increase flexibility, describing the affect this will have on the labour-automation balance.

While OEMs are making considerable investments in new and existing plants and production lines, these facilities will need to be operated to global best practice standards to build vehicles with the advanced technology features required by both the market and tightening efficiency and emissions legislation.

As an example, Chrysler has invested a combined $1.35 billion in two plants and its World Class Manufacturing (WCM) initiatives reflect a Fiat-Chrysler philosophy of utilising the best-possible practices in factory settings.

The company’s senior vice president of manufacturing/ WCM, Scott Garberding will tell delegates of the carmaker’s progress and how two plants – Sterling Heights Assembly Plant and the Toledo Assembly Complex – that faced vastly different outcomes now are following one path toward viability.

Demand outstripping supply and suppliers Booming demand for cars and trucks is driving new investment in automation across North America’s car production industry. With only 67 auto plants running in 2013 and an expected production of 16 million vehicles (compared to a 15.8 million output in 2005, with 85 plants running) facilities are being updated and carmakers and major suppliers are wrestling with making the right choices to meet extraordinary demand while adding flexibility.

Demand outstripping supply and suppliers Booming demand for cars and trucks is driving new investment in automation across North America’s car production industry. With only 67 auto plants running in 2013 and an expected production of 16 million vehicles (compared to a 15.8 million output in 2005, with 85 plants running) facilities are being updated and carmakers and major suppliers are wrestling with making the right choices to meet extraordinary demand while adding flexibility.

The latest data shows more than 100% capacity utilisation at several of the major carmakers operating in North America, something not seen for some time. How this situation will develop and how OEMs can benchmark their manufacturing strategies against global models and achieve lean manufacturing, operational excellence and effective resource planning and utilisation, will be explored in a special presentation by Michelle Hill, partner at Oliver Wyman (which acquired Harbour Consulting in 2007).

To achieve the cost reductions necessary to remain competitive, suppliers will also need to improve operational efficiency through sophisticated, long-term manufacturing strategies. Tier suppliers are very vulnerable during the present upturn; if they cannot re-energise their plants quickly to meet demand, they may go to the wall or be bought up by their OEM customers in moves reminiscent of the 1930s-1950s. But suppliers are working hard to better align their processes and methods to those of their customers, with the OEMs’ help; Chrysler is this year introducing WCM Lite, which invites suppliers into the production process for full transparency and constant communication. In the past, if supplier relations were positive, OEMs rarely had contact with them, but now there is a more proactive, communicative approach.

Addressing these and many other challenges will be the theme of the Supplier Development session on Tuesday, September 24, when OEM purchasing directors such as Stephen Harley, executive director of global material planning and logistics and parts supply and logistics at Ford, will outline what the OEM wants from the supplier community in terms of quality improvements, communication integration and manufacturing excellence.

Other important themes to be discussed at the conference include labour recruitment, training and retention. “I am looking forward to sharing my experiences in areas like labour and training, and how we build BMW super-quality vehicles in North America,” said Richard Morris, assembly vice-president, BMW Manufacturing Spartanburg, who is one of the headline speakers this year.

Speaking for the line operators and engineers’ side of the business, CAW president Ken Lewenza will talk about the formation of the new combined CAW-CEP Canadian union and how the organisation’s added strength will better equip it to work with OEMs and tier suppliers to effectively manage the demands of the boom while protecting workers’ rights and benefits.

Scott Garberding, senior vice-president, manufacturing/WCM, Chrysler

Scott Garberding, senior vice-president, manufacturing/WCM, Chrysler- Stephen Harley, executive director, global material planning and logistics, and parts supply and logistics, Ford

- Heinrich Keulmann, general manager, plant engineering, Volkswagen Chattanooga

- Richard Morris, assembly vice-president, BMW Manufacturing Spartanburg

- Tim Marasco, director, global stamping manufacturing engineering, Ford

- Ken Lewenza, president, Canadian Auto Workers union

- Gerardo Oaxaca, chief executive, Superlaser & Fixtures

- Michelle Hill, partner, Oliver Wyman (The Harbour Report)

A special feature of the AMS North America conference is its series of breakout sessions dedicated to specific technologies.

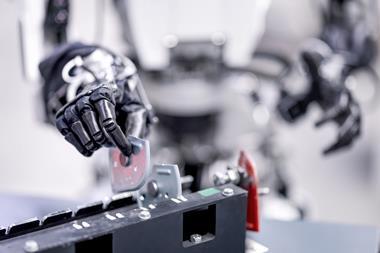

These will include stamping, plant control and IT, robots and handling, efficient energy use, the latest developments in body-in-white, paintshop and perhaps most relevant in the drive for cleaner, more efficient vehicles – powertrain developments.

The fine detail of technical and operating issues will be extensively covered, with technical experts like Tim Marasco, director of global stamping manufacturing engineering at Ford, who will present the carmaker’s strategies on building vehicle architectures for the new lighter weight cars and trucks demanded by the market and legislation.

New technology applications in body-in-white will be discussed by OEM and tier supplier manufacturing experts such as Gerardo Oaxaca, chief executive, Superlaser & Fixtures of Mexico. Oaxaca will talk about new laser processes used in a contract with a major European OEM and how these have enabled rapid and efficient adoption of high-strength steel body components that can help carmakers in their quest for lighter-weight, more fuel efficient vehicles.

Powertrain development is central to rapidly bring to market a new generation of engines that will meet demanding emissions and fuel efficiency legislations. These new motors will require sophisticated and flexible casting, forging and machining lines, and the manufacturing strategies and processes required will be discussed by OEM powertrain manufacturing engineers and machining equipment providers.

Equally vital to control the automobile’s cost to the environment is managing the power and resources used in its construction.

Equally vital to control the automobile’s cost to the environment is managing the power and resources used in its construction.

Engineering leaders such as Heinrich Keulmann, general manager of plant engineering at Volkswagen’s Chattanooga facility, will talk in a special Managing Manufacturing Power session. Keulmann will showcase the German OEM’s intelligent resource management in solar power usage, sophisticated power management systems operated through carefully planned production scheduling, and workflow implementation programming.

The event programme will include a coffee breaks and lunches with networking opportunities, and a mid conference gala dinner, plus copies of speaker presentations to download after the event, all within a single delegate fee.

The conference is organised by AMS, and is one of the global series of events that includes AMS China, held in Shanghai in June each year, AMS South America in Sao Paulo in October, and AMS India in Pune in December.