Articles (7)

-

Article

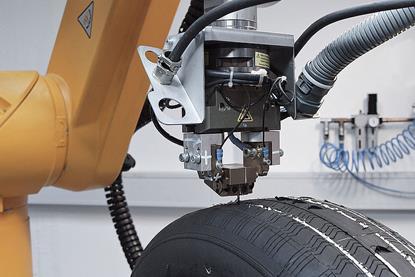

Cutting the perfect tread

Automated carving of prototype tires Prototype tires generally have their tread carved by hand. But at tire giant Continental, they like to do things differently. High-precision Stäubli robots handle the difficult task of carving with a hot blade, achieving maximum accuracy and reproducibility, and working faster than ever before. A ...

-

Article

State of emergency in the cell

Deburring and cleaning vehicle precision components Innovative robotic deburring cells use waterjets at up to 2,000 bar to simultaneously deburr and clean vehicle components. Plants rely on Stäubli six-axis HE robots, which are perfectly designed to handle the tough conditions in the cell. Maschinenbau Silberhorn has made a name for ...

-

Article

HE robots excel where others fail

Six-axis machines for inline parts cleaning 100 percent humidity and a pH of 9: in such conditions, the deployment of robots poses real challenges. These are the very parameters under which Stäubli robots are delivering reliable service on the parts cleaning line at the Nissan Dongfeng engine plant in China. ...

-

Article

The next generation of additive manufacturing

Efficient production of high-strength lightweight components The Fiber Patch Placement (FPP) systems developed by a Bavarian technology company constitute a step change in additive manufacturing. Thanks to high-performance robotics, the process has the potential to revolutionize the series production of geometrically complex lightweight parts in the automotive industry. Weight reduction ...

-

Article

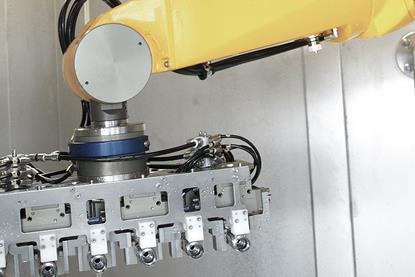

Quantum leap towards Industry 4.0 in mold manufacturing

Robot-assisted machining of molds At the highly advanced Audi Competence Center for Plant Equipment and Forming Technology, they are gradually working towards the digital linking of all processes. A robotic machining center now replaces four radial drilling machines in the manufacture of molds. Back in 2015, when Audi yet again ...

-

Article

Automated testing under extreme conditions

Quality checking of touchscreens in an environmental chamber Quality checking touchscreens within a temperature range of -40 to +85 degrees Celsius places extreme demands on robotics. Now for the first time, a Stäubli six-axis machine is meeting this challenge without the use of a protective cover. Touchscreens for use in ...

-

Article

Committed to safety

Efficient assembly of airbag control sensors TRW Systems in the county of Durham, UK, is one of the market leaders in the manufacture of intelligent safety systems and has made a name for itself as a reputable supplier of airbag control sensors. Until recently, the production of airbag modules at ...