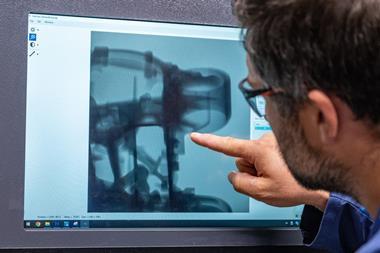

Dermot Healy speaks to CMM programmer James Mitchell about working with Faro Technologies at the Kirchhoff Automotive plant in Lansing, Michigan

Kirchhoff Automotive is one of the leading global suppliers of body structures, sub-assemblies and stamped products to major automotive manufacturers. Working closely with manufacturers from an early design stage the company uses the latest technologies in plants around the world to deliver components of consistent high quality to meet their customers’ needs.

Kirchhoff Automotive is one of the leading global suppliers of body structures, sub-assemblies and stamped products to major automotive manufacturers. Working closely with manufacturers from an early design stage the company uses the latest technologies in plants around the world to deliver components of consistent high quality to meet their customers’ needs.

Recent developments in lightweighting, and the use of new materials, pose for them new challenges in design, production and quality control. FARO offer unrivalled experience in coordinate measuring techniques and 3D measurement and imaging solutions for factory metrology applications. Its FaroArm portable coordinate measuring machine (PCMM) allows manufacturers easy verification of product quality by performing 3D inspections, tool certifications, CAD comparison, dimensional analysis, reverse engineering, and more. But how do those tasked with using FARO equipment find it performs in day to day use in their workplace?

James Mitchell, a CMM programmer with Kirchhoff Automotive working out of the Lansing, Michigan plant, spoke to Dermot Healy about the company’s experience of using FARO metrology solutions in their continued search for high quality and competitive advantage.

Dermot Healy: Kirchhoff is a massive organisation, with facilities all around the world, but give us a sense of the work you do here at the Lansing plant...James Mitchell: In this plant we are very heavily involved with General Motors, providing front-end structures, rocker panels, and assorted other sub-assemblies for various of their models. We do a lot of stuff for the Camaro models at the moment. We are a welding shop and deal with a wide range of stampings and fabrications which all have to meet our customers, and our own, very stringent quality targets.

Tell us about your involvement with FARO equipment, how did you come to choose the FARO products?In this plant we used to contract out many metrology functions and services to a third-party specialist service organisation. They used FARO equipment in their work for us. As the demand for these services grew within the organisation, the decision was made to bring metrology functions in-house, to develop our own capabilities and expertise that we could offer our engineering colleagues. Naturally we turned to FARO as we had been impressed with the results achieved using their equipment when working with the external contractors.

In fact it has turned out very well. We already knew FARO equipment could do the kind of things we needed, and our engineers had been impressed by the sophistication and reliability of data that could be captured so it was natural that we would rely on FARO. Really we did not need to turn anywhere else as once we became involved with the guys at FARO they were able to advise us on the appropriate equipment and help us understand its potential. For us here at Lansing when we were setting up our in-house facility one key factor was that FARO were able to provide training in their solutions and equipment in an effective and helpful way. They provided it in a way to suit us – so we were able to do it without disrupting existing work or drawing too heavily on staff time and resources. I went through the training with them – which proved very straightforward but comprehensive. This has made it possible for me to train up other staff here in the use of the equipment and deal with any problems that might arise.

So the training can be cascaded down with minimal disruption?Exactly. This means things can be done at our own pace, gives us flexibility, and allows us to react to staff changes and availability. We can develop a depth of competence and understanding across the section. So really the support we had from the guys at FARO in the early stages proved crucial in developing our own operation.

What equipment do you have from FARO at the moment?We started off with FARO Edge FaroArm and we have now recently added the new FARO QuantumS ScanArm HD. This combines the QuantumS FaroArm with the FAROBlu Laser Line Probe HD, delivering exceptional performance for both hard probing and laser scanning. We are very pleased with it. It brings a functionality and ease of use that is ideal for our needs. These includes applications such as checking stampings, assemblies and welding fixtures. The QuantumS ScanArm HD is very light and user friendly. Most important of all, once our engineers saw the quality of real time data that we could provide they began finding more and more uses for it. Now we get regular calls to take it to sister plants, once the engineers there realise that the data we can provide will help with their particular projects.

What equipment do you have from FARO at the moment?We started off with FARO Edge FaroArm and we have now recently added the new FARO QuantumS ScanArm HD. This combines the QuantumS FaroArm with the FAROBlu Laser Line Probe HD, delivering exceptional performance for both hard probing and laser scanning. We are very pleased with it. It brings a functionality and ease of use that is ideal for our needs. These includes applications such as checking stampings, assemblies and welding fixtures. The QuantumS ScanArm HD is very light and user friendly. Most important of all, once our engineers saw the quality of real time data that we could provide they began finding more and more uses for it. Now we get regular calls to take it to sister plants, once the engineers there realise that the data we can provide will help with their particular projects.

Did you have to convince colleagues that it was all a worthwhile investment?They were convinced straight away, and we have been kept quite busy by them ever since. What has happened now is that we have had requests from other plants within Kirchhoff from people who want to come to look and talk with us about the services we have been able to develop. We will shortly have visits here to see the set up from the guys at other plants so they can see what the equipment does, appreciate the ease of use, and understand its potential for their plants. Initially we envisaged the equipment being used on a corporate basis – across different plants – but the level of demand is such that increasingly each plant is seeking to develop their own capability. I expect we’ll be ordering more equipment from FARO to reflect this. Perhaps one other thing that I should mention is the customer service we have received from FARO. That is an important consideration for us.

How has that worked out for Kirchhoff?We really can’t fault it. Our experience has been that whenever we have had a query or problem – and you always get issues coming up when you start using new systems and equipment – the guys from FARO have responded. They have come right round and sorted everything out straight away – so that has helped build confidence. We are always under pressure so that is the kind of service that we really require. So – yes – it has all worked out very well so far.

After implementing the FARO QuantumS ScanArm solution, what were the most significant benefits recognised by your organisation?We have enjoyed the ability to take measurements directly in manufacturing and production environments, shortened inspection time and increased throughput. Implementing the FARO’s solution has helped reduce measurement and inspection time for the areas in which it has been deployed on average by approximately 60%.