- Plant Functions

- Smart Factory

ZF’s Fernando Bera on data-driven efficiency in smart factory transformation

ZF’s Fernando Bera on data-driven efficiency in smart factory transformation Gestamp’s Paul Belanger on cost reduction strategies through giga-stamping and collaboration

Gestamp’s Paul Belanger on cost reduction strategies through giga-stamping and collaboration Stellantis’ Jeremy Keating on embedding lean across the organisation for efficiency

Stellantis’ Jeremy Keating on embedding lean across the organisation for efficiency Stellantis’ Asif Khan on lean manufacturing for cost control and profitability

Stellantis’ Asif Khan on lean manufacturing for cost control and profitability

- Electrification

- Automation

- Sustainability

- Events

- Companies

- Materials

- Regions

- Kaizen

- Video and Audio

- Magazine

- Surveys & Reports

- Newsletters

- Partner Content

- Whitepapers

- Media Pack

- Register

- Sign In

Smart factories, smarter cars: AI’s impact on auto manufacturing

Volkswagen restructures German manufacturing amid industry crisis

Opel Eisenach’s Grandland EV: a lean manufacturing marvel

We want your expert opinion. Take part in the North American Automotive Manufacturing Survey 2025

BMW partners for innovation in rare earths for vehicle production

2024 to 2025, the trends and predictions in automotive production

Chinese vehicle makers look to international markets for growth

- Previous

- Next

AMS Evolution 2024

AMS Evolution 2024: Recap blog

Get insights on technologies like AI, robotics, and sustainable production systems driving flexibility and zero waste in factories at the second AMS Evolution North America Conference 2024

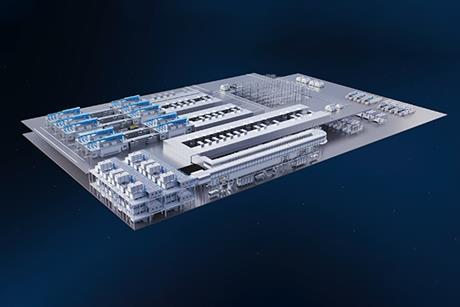

Mazda to build module pack plant for cylindrical lithium-ion batteries

Mazda’s new plant will be located in Iwakuni City, Japan and will produce battery packs for its new EVs.

Stellantis invests in €4.1 billion Spanish gigafactory with CATL

Stellantis and CATL to establish a 50 GWh EV battery plant in Zaragoza by 2026, advancing LFP battery tech and carbon-neutral production.

VW Chattanooga: a masterclass in flexible manufacturing

Volkswagen’s chattanooga plant showcases flexibility in manufacturing, transforming operations to adapt to electric vehicles and evolving market demands.

Smart factories, smarter cars: AI’s impact on auto manufacturing

Explore how AI is transforming automotive manufacturing with advanced technologies like predictive maintenance, deep learning, and generative design.

Volkswagen restructures German manufacturing amid industry crisis

Volkswagen plans to cut 35,000 jobs and relocate Golf production to Mexico, aiming to save $15.45 billion annually to recoup losses.

Opel Eisenach’s Grandland EV: a lean manufacturing marvel

Opel Eisenach pivots to exclusive Grandland EV production, merging lean manufacturing with selective automation to stay competitive amid industry transformation.

- Previous

- Next

How Henkel is co-developing the EV batteries of the future

Henkel’s €130m Battery Engineering Center advances EV battery design, testing and safety with cutting-edge labs and global expertise.

Honda sets up a demonstration production line for all-solid-state batteries

Honda’s demonstration production line will support development for the mass production of solid-state batteries.

Stellantis’ Jeremy Keating on embedding lean across the organisation for efficiency

Embedding lean practices across all departments and fostering early-stage collaboration are essential for Stellantis’ manufacturing efficiency, says Jeremy Keating.

- Previous

- Next

- Previous

- Next

Rolls-Royce invests £300m to extend Goodwood manufacturing facility

Rolls Royce’s £300m site extension will expand Bespoke and Coachbuild capabilities and support future EV production.

Smart factories, smarter cars: AI’s impact on auto manufacturing

Explore how AI is transforming automotive manufacturing with advanced technologies like predictive maintenance, deep learning, and generative design.

Volkswagen restructures German manufacturing amid industry crisis

Volkswagen plans to cut 35,000 jobs and relocate Golf production to Mexico, aiming to save $15.45 billion annually to recoup losses.

Mazda to build module pack plant for cylindrical lithium-ion batteries

Mazda’s new plant will be located in Iwakuni City, Japan and will produce battery packs for its new EVs.

Opel Eisenach’s Grandland EV: a lean manufacturing marvel

Opel Eisenach pivots to exclusive Grandland EV production, merging lean manufacturing with selective automation to stay competitive amid industry transformation.

Latest Webinars

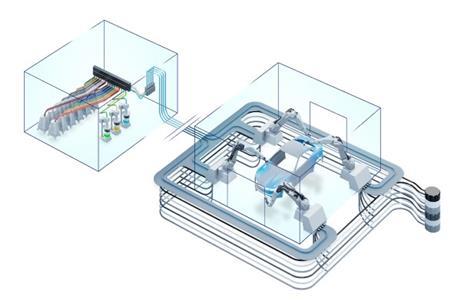

Watch now: How to maximise efficiency in battery tray manufacturing and integration

Watch Now: Next-Gen Gapfillers: Henkel’s Blueprint for Automotive Electronics

Watch on demand: Sustainable Steel Automotive Manufacturing Survey 2024 Webinar

Watch Now: Shaping the future: How electric vehicles are driving manufacturing decisions

Watch: The advance of automation: what next-gen vehicles and batteries mean for robotics

Watch: The future of battery production - making electric dreams reality

Watch: Structural change – Developing vehicle architectures optimised for EV manufacturing

Watch: S-in-motion® B Segment battery protection: a sustainable solution at an affordable cost

Watch: Next-gen car body building

Watch: SaaS Solutions for the Automotive Industry: Unlock Smart Manufacturing for a Quick ROI

- Previous

- Next

Latest Whitepapers

New eBook: Better, faster, more affordable EV battery manufacturing

Sustainable Steel Automotive Manufacturing Survey 2024 results

Henkel Whitepaper: Sustainable Processing Solutions for Automotive Manufacturing

AMS & ABB Automotive Manufacturing Outlook Survey 2023 results: A positive outlook despite evolving challenges

Whitepaper: Thermal Potting for EV Components

Case Study: Daimler Relies Upon HiveMQ During Automotive Manufacturing

Whitepaper: Revolutionary 1-Step UV LED Cure Adhesive for Automotive ADAS Cameras

Whitepaper: Optimizing Global Operations and Supply Chain for Automotive Manufacturing with MQTT Sparkplug

Automotive ADAS Camera White Paper

White paper: Streamlining EV battery production

- Previous

- Next

Latest Videos

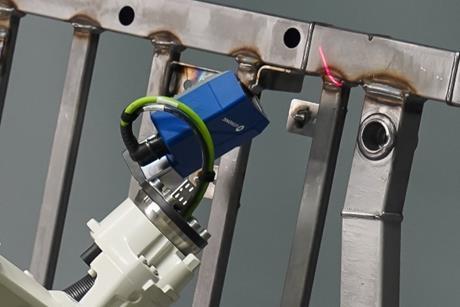

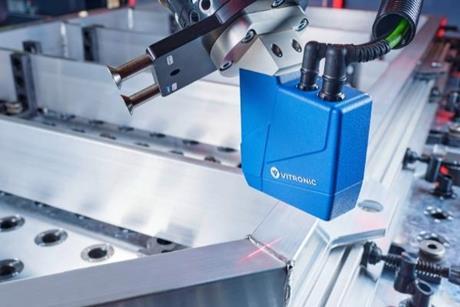

Watch: Automated weld seam inspection of EV-battery trays with VIRO WSI

Watch: It becomes colorful: EcoSupply P – Special paint supply

Watch: EcoDryScrubber – paint booth efficiency through dry separation

Watch: The Paint Shop of the Future: flexible, scalable, efficient

Watch: Global automotive parts manufacturer saves nearly $2M with energy insight solutions

Watch: #FreeRunner: EcoProFleet & DXQlogistics.control

Watch: Make robotic sanding easier with the ATI AOV-10 Robotic Orbital Sander

Watch: Maximum safety on battery housings by automated weld seam inspection

Watch: NEXT.assembly: The future is now

Watch: See how Ewellix linear motion solutions support assembly automation

- Previous

- Next

Podcasts

Managing materials choices – Fossil-free steel – AMS Expert Interview with SSAB

SSAB has produced and sold its Fossil-free steel, which is now being used in limited series production by Volvo

- Previous

- Next

![Asahi Kasei Canada groundbreaking ceremony[48]](https://d2oevnekjqgao9.cloudfront.net/Pictures/252x172/1/5/6/326156_asahikaseicanadagroundbreakingceremony48_273505.jpg)