How BMW is ‘Designing for Circularity’ to become a sustainability leader in automotive production

BMW’s Roberto Rossetti, Total Vehicle Life Cycle Development, elucidates BMW’s innovative ’Design for Circularity’ approach. From using recycled materials to optimising vehicle disassembly, BMW is redefining how vehicles are produced and consumed.

With snowballing environmental demands, nothing in automotive production can now legitimately be considered ‘progress’ without related sustainability efforts baked-in. BMW has committed to becoming a leader in circular economy practises, with ‘Design for Circularity’ being implemented across vehicle development to allow for these sustainability efforts to be realised as part of the OEMs holistic production cycle.

Secondary First: BMW’s material focus to enable sustainable production

Overarching these principles, the ’Secondary First’ guideline is a clear and fundamental goal of product design – maximising secondary raw material wherever possible.

Roberto Rossetti, Total Vehicle Life Cycle Development, BMW Group, says, “the four principles are implemented in the product development processes at an early stage, by defining clear targets.

“Following the ’Secondary First’ approach, we will increase the use of secondary raw materials in the future.

”We are taking market availability and technical feasibility into account when determining product-, material- and supplier-requirements; prioritising the use of secondary materials in all future vehicles; while – of course – ensuring that the quality, safety, aesthetics and reliability requirements of our products are always met with the same high standards as primary materials.”

“These experiences form an important basis for continuously improving sustainability and developing innovative solutions for future-oriented mobility.”

The BMW i Vision Circular and the future of circular production

The BMW i Vision Circular represents the BMW Group’s imagination for a circular future mobility; a fully-electric, fully-sustainable concept which emphasises using 100% recycled materials and maximising recyclability, based on the OEMs four circular design principles of Re:think, Re:duce, Re:use and Re:cycle. The vision also influences current production models, with steps being taken to translate it into mainstream manufacturing.

Rossetti says, “the purpose of our vision vehicles is to present strong visions for the future. They offer an outlook into the future of automotive design and experiences.

“The BMW i Vision Circular gives a glimpse of a compact BMW with an uncompromising focus on sustainability and circularity. The four-seat vehicle is fully electric-powered and offers a spacious interior within a length of around four metres. At the same time, it was consistently designed according to the four ’Design for Circularity’ principles and the ‘Secondary First’ guideline.”

For the series production vehicles, BMW approaches these principles through different steps: Continuously aiming to increase the percentage of secondary raw materials, focusing on materials that are compatible for recycling, and optimising vehicles for easy and quick disassembly at the end-of-life.

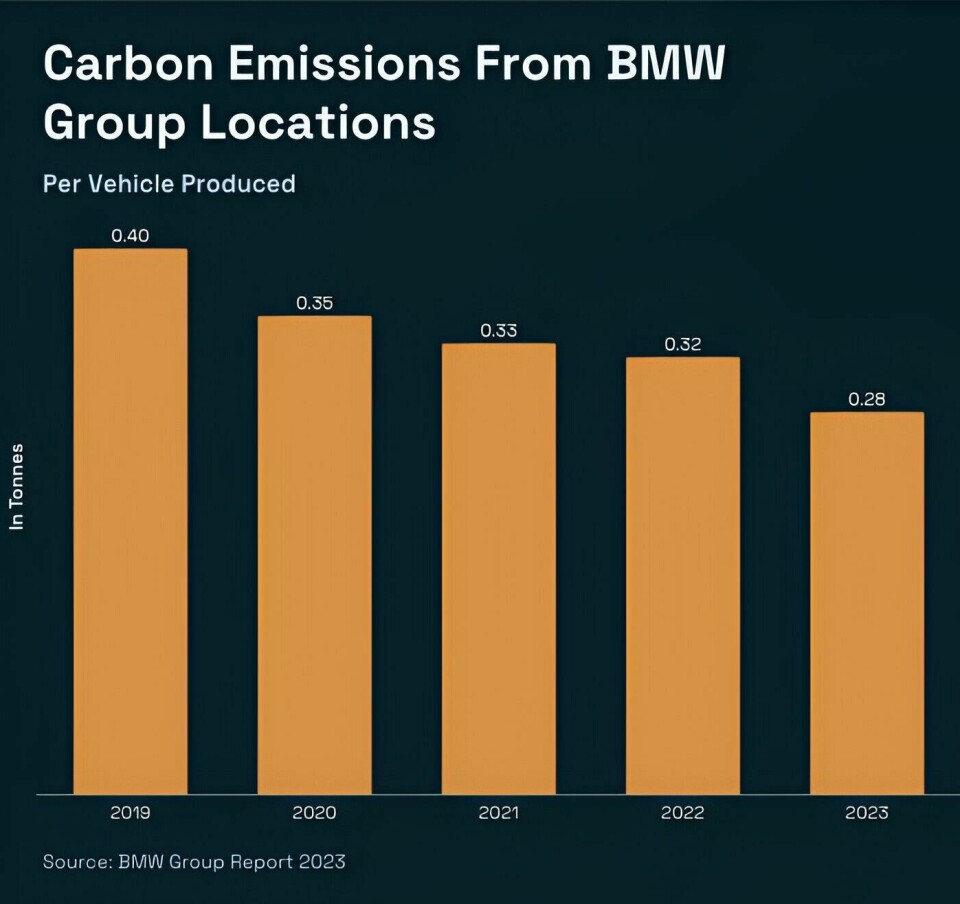

“Reducing CO2e emissions over the entire life cycle of a vehicle, as well as circular economy, is a significant part of our strategy”2

In 2025 the BMW Group will start production of the Neue Klasse and thereby raise product sustainability to the next level. “Electrification, circularity and digitalisation are the central elements of this transformation,” says Rossetti.

BMW’s use of Mono-materials to underpin recyclability and circularity

The carmaker is focusing on mono-materials to enhance recyclability. As with any project of such major proportions, there have of course, been challenges as well as innovations arising from the approach, including in balancing aesthetics and sustainability. Rossetti emphasises that the OEM’s vehicles are designed with the highest standards for design and driving pleasure. “At the same time,” he says, “reducing CO2e emissions over the entire life cycle of a vehicle, as well as circular economy, is a significant part of our strategy.

“The recyclability of components depends primarily on the materials we use. One of our current challenges is to cluster the right materials and rethink the connection technology. The BMW Vision Neue Klasse provides a good example: The front bumper in black is not only a contrasting design element, but it also has an increased percentage of secondary raw materials, fewer materials, and allows for easier dismantling.

“The bumper covers can quickly be dismantled at the end-of-life and the different materials can be better separated in the recycling process. Improved material separation, in turn, helps to increase material purity in the recycling process to gain higher quality recycled materials for new components.”

Efficient disassembly and mono-material components are core measures to create more circularity and are thus essential for recyclability. But the use of mono-materials must not lead to any negative effect on aesthetics, safety, or quality of our products. “Our customers’ expectations and our brand’s overall premium approach go hand in hand with our sustainability goals - there is no room for compromises. Finding solutions that reconcile aesthetics and sustainability is a key driver for our design and engineering team,” he says.

“To give you an example of how we realise that approach already today, I would like to refer to our current product portfolio: The latest model generation of the BMW 1 Series offers the Econeer seat cover which is based on PET mono-material. The secondary raw material content is 100% in yarn and 85% in fleece. Furthermore, disassembling the Econeer from the seat proves much easier than with conventional seat designs.”

“We are working closely with our suppliers to ensure that these materials are available in sufficient quantities and quality”

The environmental impact of BMW’s ‘Secondary First’ initiative: Production and Supply Chain

Effective climate protection requires circularity, which is therefore more and more in the focus of BMW’s engineering and development efforts. Already today, the vehicles of the BMW Group are manufactured using secondary raw materials.

According to the ’Secondary First’ approach, the OEM is expanding the use of secondary raw materials in the future - taking into account market availability and technical feasibility. “For this purpose, we specify the level of secondary raw material content in each selection process regarding product, material, and supplier,” says Rossetti.

“We are working closely with our suppliers to ensure that these materials are available in sufficient quantities and quality – supported by the cross-sector data ecosystem ‘Catena-X’. Market participants can use this platform to share all relevant data for circular economy – ensuring a more efficient, circular flow of materials. In addition, we define targets and minimum levels of recyclability that need to be reached within the supply chains.”

Furthermore, the CO2e footprint of the supply chain is an essential criterion in discussions with BMW’s suppliers next to the content of secondary raw materials and the use of green electricity. The BMW Group is supporting the transformation to less CO2e-intensive manufacturing processes such as in steel production.

The carmaker’s global production network is already a model of resource efficiency. It began early to make its vehicle production more resource efficient. Year after year, it has been able to reduce the volume of waste per vehicle, as well as its water and energy consumption. “For this,” says Rossetti, “we rely on recycling concepts that are tailored to waste flows at the plants, the region’s legal requirements and the disposal structures available at the site.

“With the BMW iFACTORY – our global strategy for efficient, more environmentally-compatible and digital production – we are taking the next step towards circular production. This includes advancing digital sorting of production waste.” All these aspects will come together in the BMW Neue Klasse from 2025 onwards.

BMW’s Recycling and Dismantling Centre (RDZ) in Munich, plays a crucial role in vehicle disassembly and material recovery. From this centre, the OEM has learned many lessons which have influenced the design of future BMW models to ensure better recyclability.

More Sustainability Stories from BMW

- BMW and Toyota collaborate on powertrains for hydrogen FCEVs

- BMW builds gigafactory for Neue Klasse in Mexico

- Exclusive: BMW Group improves efficiency with additive manufacturing gripper

- How BMW is ramping up its circular production principles

To drive the implementation of a circular economy, as mentioned, the BMW Group focuses on its principles of ’Design for Circularity’. The OEM designs vehicles in such a way that they can be repaired - and components can ideally be reused or recycled - at the end of their service life. To achieve this goal, teams from the various departments of development and after-sales work closely together and share their knowledge.

Hence the RDZ keeps in continuous contact with the development department. In particular, the opportunities and challenges of dismantling components are shared with development experts. Another focus to drive this process is the use of mono-materials or a combination of materials easy to recycle or segregate.

“All in all,” says Rossetti, “the RDZ has repeatedly supported the development of new models, materials, and technologies by providing advances in recycling already over the past three decades.”

BMW’s approach to sustainable seating and design

The carmaker has also made significant strides in sustainable seating design, such as the award-winning M Visionary Materials Seat. This project, too, reflects BMW’s broader circular design goals.

As a platform for research on future materials, the award-winning BMW M Visionary Materials Seat focuses on the following key topics: Firstly, driving the use of plant-based materials, secondly, as part of ’Design for Circularity’, raising the content of secondary raw materials, and thirdly, increasing recyclability at the end of the lifecycle.

“One of our biggest lessons was the balancing, in other words, of how to model our process chain to generate missing primary data,” explains Rossetti. “The data obtained provides new insights, both in terms of today’s negative contributing factors and the design of tomorrow’s processes. This experience provides a solid foundation reaching our sustainability goals and developing innovative solutions for forward-thinking mobility.”

Collaborative efforts to ensure consistent, sustainable material flow

Given scarce resources, volatile commodity prices, geopolitical tensions and sustainability requirements, circular economy is becoming more and more important. Therefore, the BMW Group is taking further measures to increase the ratio of secondary raw materials in products and thus reduce dependency on primary raw materials and conserve resources.

An important approach is to keep materials and components in a closed loop and pursue a holistic approach to circular-oriented product design. For example, the carmaker is returning selected production scraps to suppliers to recycle the materials and incorporate them into new production processes. Furthermore, it is strengthening its local supply chains according to the ‘local for local’ principle. “In this way,” says Rossetti, “we are consistently continuing on our path across both production and supply chain to conserve resources, continuously improve energy efficiency and reduce CO2e emissions even further.”