Mercedes-Benz has entered into an agreement to explore the use of Apptronik’s humanoid robots for its automotive manufacturing ecosystem

The carmaker partners with Apptronik to integrate Apollo robots, potentially revolutionising production lines with collaborative automation, addressing labour challenges and advancing the future of automotive manufacturing.

Mercedes-Benz has entered into an agreement with Apptronik, a leader in next-generation general purpose humanoid robots. As part of the agreement the two companies will collaborate on identifying applications for highly advanced robotics in the OEM’s Manufacturing ecosystem. If successful, Mercedes-Benz will bring one of the world’s most advanced commercial humanoid robots “the Apollo”, into its manufacturing facilities, marking the beginning of a new era in automotive production.

The carmaker is also exploring potential use cases for the humanoid robots as part of its logistics ecosystem to bring parts to the production line for worker assembly, the delivery of assembly kits, and component inspection. Apollo will also be used to deliver the totes of kitted parts later in the manufacturing process.

The addition of humanoid robots into factories and plants has the potential to allow automotive OEMs to deploy robotics that are optimised to perform in spaces that are designed for humans; avoiding full-scale facility redesigns that are built around robots rather than people. Seen through the labour-lens, the technological approach will revolve around automating physically demanding and repetitive tasks for which it is becoming increasingly difficult to find reliable workers.

“When we set out to build Apollo, an agreement like the one we’re announcing today with Mercedes-Benz was a dream scenario,” said Jeff Cardenas, co-founder & CEO of Apollo. “Mercedes plans to use robotics and Apollo for automating some low skill, physically challenging, manual labour – a model use case which we’ll see other organisations replicate in the months and years to come.”

Humanoid cobots in automotive production

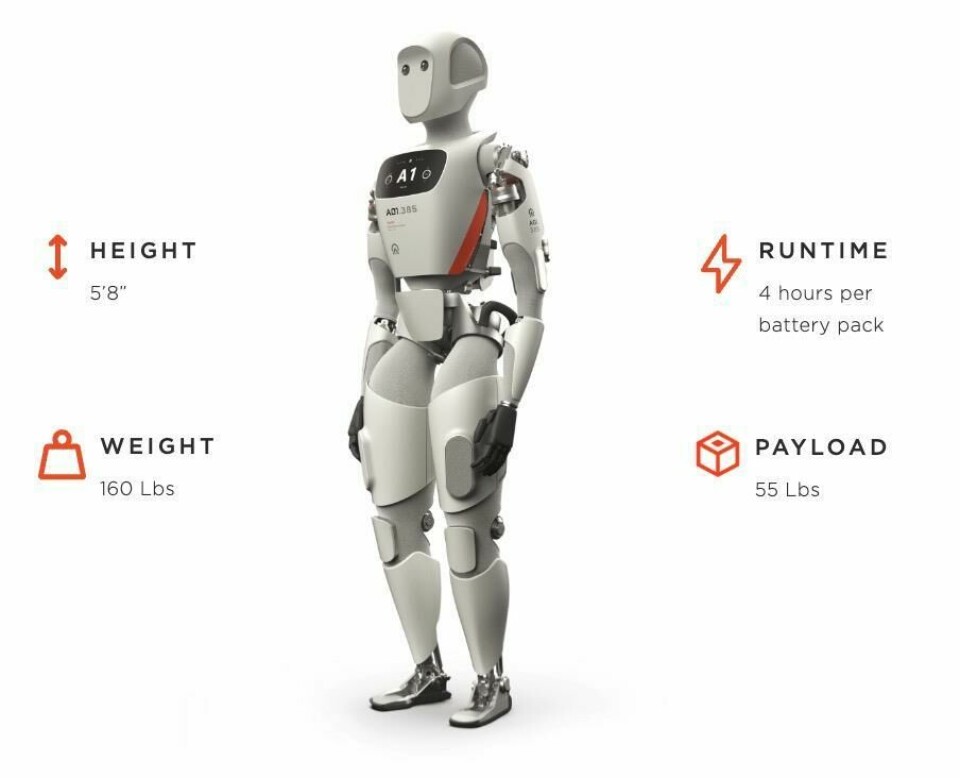

The Apollo robot is engineered to human dimensions, standing at 5 feet 8 inches tall and weighing 160 pounds (72.6kg), with a lifting capacity of 55 pounds (25kg). Tailored for operation within industrial settings, Apollo is designed to integrate into workspaces alongside human counterparts.

Equipped with a distinctive force control architecture ensuring safe interaction with individuals, and said to be collaborative robots (cobots) rather than traditional industrial counterparts, Apollo’s user-friendly design is said to facilitate cooperation with human operators while effectively executing physically demanding tasks.

Integrating industrial humanoid cobots with Artificial Intelligence

Additionally, Apollo’s computing power makes it possible for leading AI companies to solve use cases outside the ones that Apptronik will initially solve, similar to the iPhone concept: world-class, user-friendly hardware that comes with some pre-built applications and can add applications developed by third parties.

“To build the most desirable cars we continually evolve the future of automotive production: Advancements in robotics and AI open up new opportunities also for us,“ said Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production, Quality & Supply Chain Management.

“We are exploring new possibilities with the use of robotics to support our skilled workforce in manufacturing.

“This is a new frontier and we want to understand the potential both for robotics and automotive manufacturing to fill labour gaps in areas such as low skill, repetitive and physically demanding work and to free up our highly skilled team members on the line to build the world’s most desirable cars.”