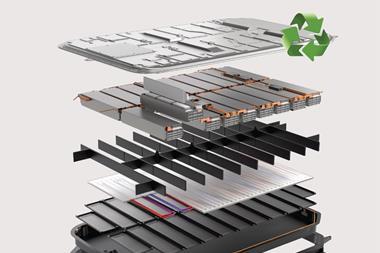

UK – The FW-EVX concept features innovations in the battery pack, cooling systems and lightweight structures which are integrated into a scalable platform, says the company. A near zero-waste process and the forming of high-strength 3D structures from 2D materials are used for parts of its construction.

UK – The FW-EVX concept features innovations in the battery pack, cooling systems and lightweight structures which are integrated into a scalable platform, says the company. A near zero-waste process and the forming of high-strength 3D structures from 2D materials are used for parts of its construction.

The near zero-waste process, which is also highly automated, is applied to the manufacture of fibre-reinforced suspension components, which are claimed to reduce weight by 40% compared with a conventional, aluminium wishbone. The process of forming strong 3D structures is used to create an exoskeleton for the battery module which contributes to the structural performance of the battery.

“These technologies, and our thinking around how to create a tightly integrated, lightweight chassis and powertrain package, have the potential to greatly increase the competitiveness of the next generation of electric vehicles,” said Paul McNamara, technical director at Williams Advanced Engineering.

The new platform was developed by in-house specialists in aerodynamics, electrical systems, advanced lightweight structures and vehicle integration; patents are pending.