Specifying the perfect electrification solution

Magnus Nordstrand, Product portfolio manager, ABB E-mobility motors, explains the essential decisions that will help solution providers electrify industrial and heavy-duty transportation.

Industrial and heavy-duty vehicles are essential, but they are responsible for a significant portion of global emissions. In the EU, for example, non-rail transport vehicles – a category that includes buses and many industrial vehicles – make up 5% of all vehicles but produce approximately 25% of vehicle CO2 emissions.

Necessary but highly-emissive industries, such as mining and construction, are looking to reduce their environmental impact on as many operational levels as possible. That means electrification can offer an opportunity to meet their sustainability targets while also benefitting from increased productivity and environmental improvements, resulting in better health outcomes for operators and the surrounding community.

Policy changes are another factor pushing many operators to electrify. Some cities, for example, have created incentives for electric vehicles, penalties for emissions, or even banned internal combustion engines altogether.

However, there is no “one-size-fits-all” solution. Every application and operating environment is different, and today’s various solutions have their own advantages and disadvantages. It is important that OEMs and solution providers consider the various options available and pass along the unique benefits of each option to their end-users and customers.

“For a large and increasing number of use cases, full electrification is possible – including the propulsion and any auxiliary equipment, like the hydraulics for moving the bucket or forks”

Diesel, hybrid or full electric?

The first choice that solution providers must make is whether to specify a diesel, hybrid or fully electric drivetrain. In certain cases, diesel may still be necessary due to its superior energy density, although electrification technology is advancing at a rapid pace.

For applications that still require a high autonomous range, such as in forestry, a hybrid solution that combines diesel and electric drivetrains is appropriate. While pure diesel solutions rely exclusively on a combustion engine, running regardless of efficiency, a hybrid system can enable the diesel engine to work at peak efficiency, further reducing the amount of fuel required.

For a large and increasing number of use cases, full electrification is possible – including the propulsion and any auxiliary equipment, like the hydraulics for moving the bucket or forks. These systems can be served by individual electrical drivetrains to further increase reliability and efficiency. Full electric vehicles can lower operating costs by 40 to 60%.

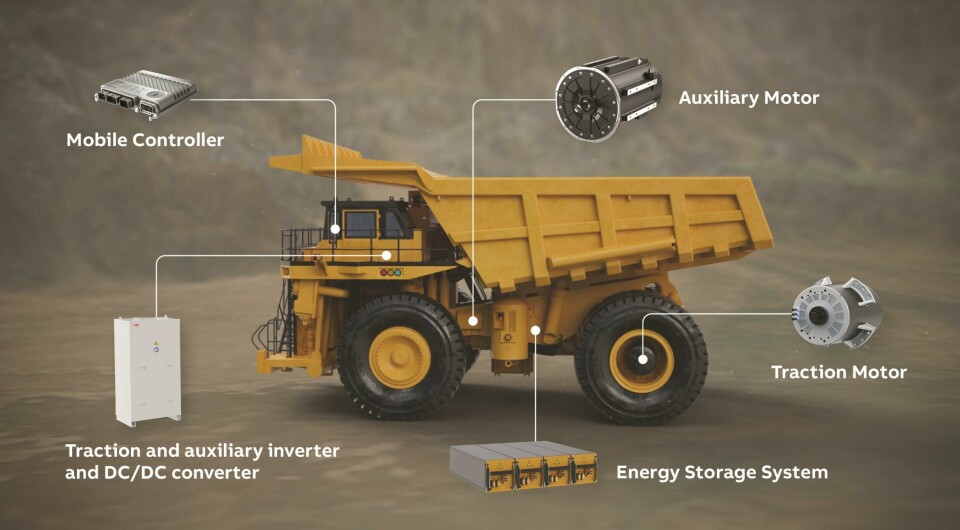

It is possible to retrofit diesel vehicles to operate on battery power or a direct connection to the grid. For example, Nasta AS, one of Norway’s largest suppliers of excavators, has collaborated with ABB to convert several diesel vehicles. The diesel motor is removed from the vehicle and replaced with electric motors, drives (also known as inverters), an energy storage system, and a charging system.

The resulting vehicles do not produce CO2 or SOx emissions on site and are significantly quieter, which makes them ideal for use in urban environments. Every 24-ton diesel excavator that Nasta electrifies eliminates approximately 48 tons of CO2 emissions per year.

Choosing the right power supply

Once solution providers have decided on a hybrid or electric system, they must next choose an appropriate power supply. The right choice depends on the use case.

If a vehicle is not required to move far beyond a set point, such as an excavator that performs a large amount of its work while stationary, a direct grid connection is ideal. These vehicles can also be equipped with a small battery so that they can move a short distance between grid connection points. This battery can also provide peak shaving capability to boost the available power when the load is particularly high, such as when an excavator is lifting a fully loaded bucket.

Batteries provide electricity on the move, but they are heavy and may not yet have the capacity for all-day operation. Larger vehicles require larger batteries, so they can have a significant impact on a vehicle’s unladen weight. Battery technology is continually improving, and over time operators can expect energy density to increase and costs to decrease.

Batteries also require charging, and we can roughly split them into two categories. The first are power batteries, which charge and discharge quickly, resulting in many charge-discharge cycles within a given period. They are often integrated into vehicles and not removed for charging.

The opposite type are energy batteries, which charge and discharge more slowly. These can be specified for battery swapping. For example, a haul truck in an underground mine making several trips back and forth every day could continually swap out its batteries to remain in operation. The old battery charges while the new one is in operation, reducing the time a vehicle has to wait for a charge.

If multiple vehicles frequently move along the same route, catenary wires can be suitable. You can even specify hybrid catenary setups, which charge a vehicle’s batteries while it is in motion along a frequently travelled route – such as a mining truck that travels up and down the same climb every trip.

In Zurich, Switzerland, public transport operator VBZ partnered with ABB to replace its fleet of diesel buses. The replacement vehicles use a combination of onboard battery power and catenaries. The batteries charge on sections of the route with catenaries, providing power for the sections without catenaries. This solution simplifies future expansion and improves the air quality in the city.

One consideration with a catenary approach is that it requires a significant investment in infrastructure which cannot be easily moved to other sites – but this is not an issue for permanent locations, where it often makes economic sense. Both catenaries and direct grid connections often require upgrades to the electrical network infrastructure, so these costs must also be included in any calculations. In some cases, a peak shaving battery solution could help to reduce the need to upgrade the power supply network.

Regenerative braking opportunities

An important consideration is the use of regenerative braking technology within a vehicle. Regenerative braking systems (RBS) are common in road and rail applications.

Although regenerative braking technology is most mature in propulsion applications, it is now available for the recovery of energy from hydraulics. This technology will continue to mature in the years ahead.

When investing in an RBS, solution providers must consider the amount of energy it can produce and store. The energy available for the system to recapture depends on a range of factors, including the vehicle type, load, slope, and more. It is therefore important to account for the site’s layout. An ideal scenario involves a vehicle driving downhill carrying a load – an efficient RBS could capture enough power to supply the drive back uphill without the load. At ABB, we are currently working on mining applications where this is possible.

The system design is also essential. A suitable motor for an RBS must act efficiently both as a motor and as a generator to recapture energy. Solution providers must therefore consider these two operating ranges and specify the right motors for the use case. Another consideration is that sufficiently high losses in the motor and inverter can eliminate the benefit of an RBS. To address this, solution providers should specify components with low electrical losses.

Permanent magnet motors intended for use in heavy vehicles are designed with these considerations in mind. ABB’s AMXE® permanent magnet synchronous motors, for example, are compact and highly efficient. Solution providers can configure these motors’ lengths, windings, and voltages to suit their applications.

Motor voltage is another important factor, as induced voltage limits can limit a vehicle’s speed. Back electromotive force (EMF) acts against the voltage applied to make the motor spin, producing high voltages that can damage components such as motors, drives and batteries.

Considering drives and arrangements

It is important to look beyond just the price tag when specifying a drive. Different models have hugely different capabilities, and more expensive drives often recover their cost faster in OpEx savings than cheaper ones.

Some drives are intended only for driving a motor, meaning that they are not capable of regenerative braking. Others are designed to operate in the field-weakening area, where motors require additional speed range. So, there are multiple factors to consider when specifying a drive.

Typical designs pair each motor with a single drive. In lower power ranges for certain applications, multiple motors can be controlled by a single drive, but heavy road vehicles typically use a 1:1 ratio to ensure that the drives are an appropriate size. In applications where space is less of a concern, such as trains, controlling multiple motors from one bigger drive is an option.

Designing for a sustainable future

As global emissions targets become increasingly strict across all industries, electrification represents a valuable opportunity for solution providers. Demand already exists, and it’s up to leading solution providers to meet it. By making the right choices today, with the support of businesses like ABB, solution providers can play a pivotal role in our global journey to Net Zero.

Learn more at ABB Sustainable Transport