Despite industry fears, global EV sales reach record highs in 2024 and remain on an upward trajectory

How will slowing growth in EVs impact auto industry investment strategies? As the industry navigates challenges from rising costs and charging infrastructure gaps, to consumer range anxiety and rising competition, Daniel Harrison explodes some EV myths.

Separating the hype (cycle) from the reality

Since the beginning of 2024, it has been widely reported that EV sales are ‘slowing’, ‘falling’ or have even ‘crashed’ and this has become accepted as a truth.

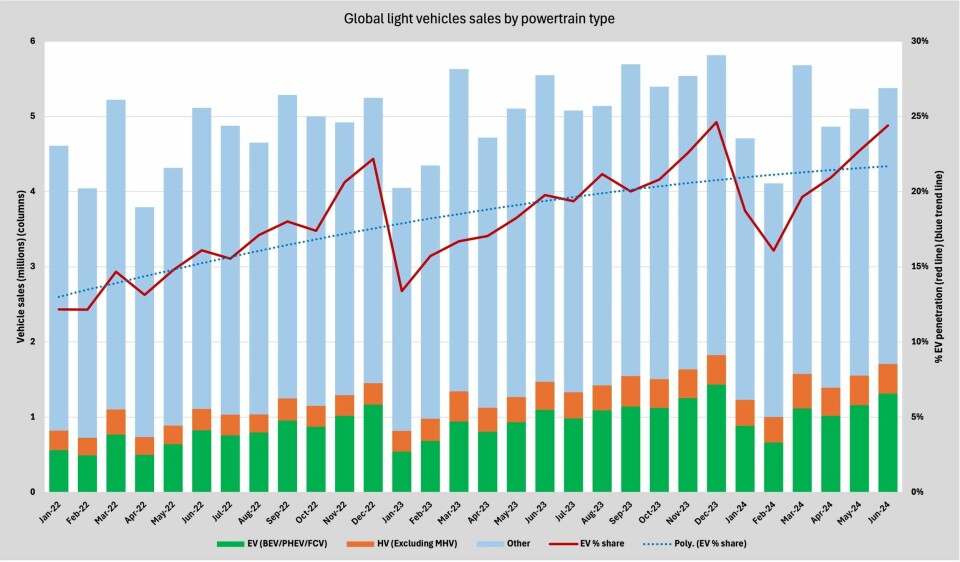

The mistake that many commentators are making is to ignore the global context and instead cite just one particular month (ignoring the annual EV sales cycle – see Figure 1), one specific region (when other regions are doing much better), or an individual OEM (who may just have a weak product offering), and then apply that finding to the global EV market.

Yes, there has undoubtedly been some monthly volatility and fluctuations, but fundamentally, the data simply does not support the view that EV sales are in decline. See Figure 1.

So what does the global data actually show?

If we look at the leading 15 EV country markets globally, which account for over 90% of the EV market, EV sales in the first half of 2024 were 6.15 million (21% of the market) and higher than they have ever been. ‘EVs’ here are defined as BEV + PHEV +FCV. See Figure 1.

The reality is that the rate of growth in EV sales is slightly slowing, and is not continuing at quite the rapid previous growth rates or that of industry expectations. To use an automotive analogy, it’s rather like the way when you accelerate hard in a car and suddenly take your foot off the gas pedal, it feels like a deceleration when it’s actually just returning to more of a steady state.

But let’s be clear, global EV sales for 2024 are still on an upward trajectory, and are expected to continue to grow, albeit at a slightly slower pace than previously expected. As Bloomberg recently confirmed, “Reports of an electric vehicle slowdown have been greatly exaggerated.

Figure 1: Global light vehicles sales by powertrain type 2022-2024

Globally speaking, hybrids have also grown at a comparable rate to EVs so the data also does not support the perception that hybrids are suddenly being favoured by consumers instead of purchasing ‘full’ EVs. What appears to be occurring is that in Europe and North America where EVs are more expensive than ICE, some consumers are choosing hybrids as a cheaper alternative. And OEMs are happy to pivot to that demand as hybrids are more profitable for them than loss-making full EVs. Conversely in China, where price parity has already been achieved between EV & ICE, then hybrids have much less appeal, and consumers are more willing to make the leap to a full EV.

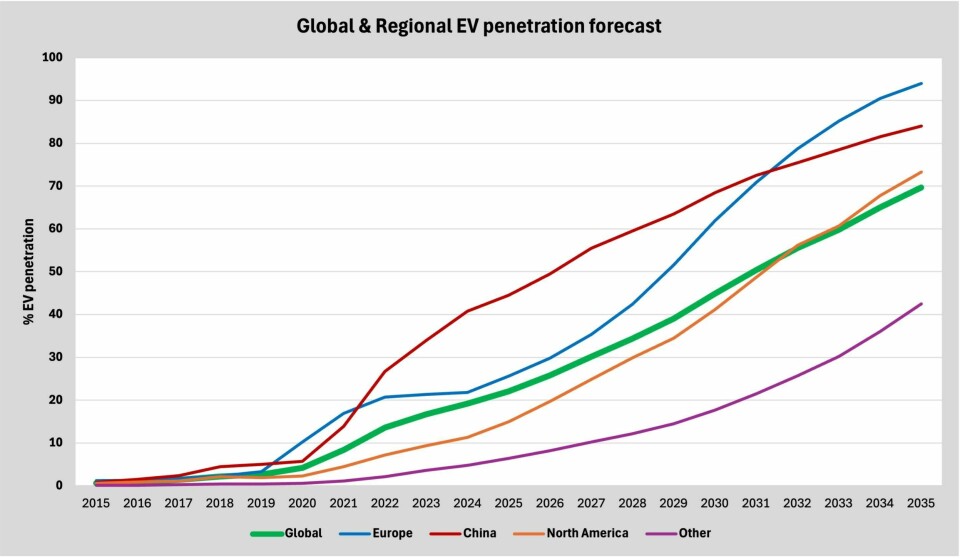

Globally, yes, in the medium to longer term there has been a slight downward revisions of forecasts for EV growth between 2024 and 2028, but the overall forecast is still overwhelmingly positive. See Figure 2.

But of course, there are also regional variations in EV sales. Europe initially took an early lead in EVs penetration rates from 2020-2021, and was expected to match China’s pace of EV transition.

However, European EV penetration rates in particular flatlined in 2023 and 2024, In contrast, China continues to accelerate and is now the leading market in terms of EV penetration. North America remains below the global EV average for EV penetration and EV growth has slowed there too. Other regions exhibit a relatively low rate of EV penetration and will continue to lag the global picture. (See Figure 2).

Figure 2: Global & regional EV penetration forecast 2015-2035 (%)

So why is there a perception of slowing EV growth?

From a consumer perspective the realities of EV ownership are starting to set in. Alluding to the ‘hype cycle’, essentially the EV market is progressing from the ‘peak of inflated expectations’ to the ‘trough of disillusionment’, and that creates a number of challenges.

| Table 1: EV adoption challenges |

|---|

| Moving from the ‘early adopter’’ phase to ‘mass market adoption’. As demand from wealthier early adopters has been met, mainstream consumers are proving harder to please in terms of the viability and practicality of transitioning to an EV. There is also some evidence that some early adopters are now trading back to ICE – even Tesla owners, because of the poor EV usage experience. |

| High purchases cost. EVs are still around 20-30% more expensive than comparable ICE vehicles. As automakers try to fit larger batteries to alleviate range anxiety this only increases the EV’s cost. The long-promised EV-ICE price parity of ~2025 remains a distant dream. Consumers can also see Chinese EVs and are considerably cheaper and are starting to question why legacy auto EVs are so expensive. |

| Removal of purchase subsidies and usage incentives. Many countries have largely removed (often quite suddenly such as the UK, Germany, and France) purchase subsidies and usage incentives and this has made the EV-ICE price gap seem even wider. |

| Charging infrastructure disappoints. Whilst range anxiety has been reduced, this has now been replaced by charging anxiety – the fear of not being able to find a charging point. The myriad of charging apps, cards and systems leads to a fragmented, confusing and frustrating consumer experience. Furthermore, whilst many EVs are now capable of charging speeds of 100KW or more, the reality is that the vast majority of public chargers are only 7KW to 22KW or less. |

| Increasing electricity costs. Whilst wholesale electricity costs increased post Covid, the previous price / per mile advantage of an EV has now all but evaporated. Further, on-street charging providers, especially rapid chargers, charge up to twice domestic electricity rates. |

| Technological obsolescence. EVs have become a victim of their own success. Huge investment has seen rapid advances in EV battery technology – but the downside of that is that consumers don’t want to invest too early for fear that they will be left with obsolete technology in just a few years- see next point on depreciation - and are instead waiting for the technology to mature. |

| Rapid depreciation and plummeting residual values. Oversupply of EVs on the used car market and rapid technological advances has led to spectacular falls in used EV prices, making new EV prices seem very poor value. |

| Higher TCO than anticipated. Due to higher crash repair costs, EV insurance is now higher than ICE vehicles. Combined with high electricity prices, collapsing residual values, and withdrawal of purchase / usage incentives, owning and running an EV has little or no price advantage anymore and can often be more costly than running an ICE. |

| Protectionism and import tariffs. Ironically the attempts by the US and Europe to protect their domestic car industries by imposing import tariffs upon cheaper Chinese EVs is actually preventing affordable EVs from getting to market and hampering the transition to net zero. |

Source: Ultima Media

But what of the auto industry itself?

The automotive industry perspective

Fundamentally the automotive industry is already heavily invested in the transition to electrification with multi-billion dollar investments already committed. However, the challenge has been that most legacy OEMs are being forced to produce EVs by regulators, but those EVs are still loss-making. Whilst that is the case there is an incentive for OEMs to sell as few EVs as they can to meet minimum interim emissions targets. However, there are some positive signs that battery and EV production costs will start falling soon.

| Promising Indicators: Battery and EV Production Costs Poised to Decline Soon |

|---|

| Price wars. Tesla started the EV price war, and the flood of Chinese EV startups trying to penetrate western markets has accelerated the trend. This will put a downward pressure on prices and should ultimately make EVs more affordable. |

| New battery technology. eg. rapid advancements in battery technology are occurring such as introducing more lower cost LFP chemistries, lithium sulphur, and eventually solid-state batteries with faster charging, higher density, and longer driving ranges. |

| Battery prices falling. Slowing EV growth has led to overcapacity across the battery supply chain resulting in falling commodity prices such as nickel, cobalt, and lithium, which is already starting to feed into lower battery prices. |

| Next generation of cheaper EVs. Many OEMs are soon to bring a range of much lower cost EVs to market. In particular from the legacy OEMs and their joint ventures with Chinese EV companies. E.g. VW & Xpeng, Stellantis & Leapmotor, GM & SAIC, Ford & Changan etc. |

| The ‘Super Election’ year in around 80 countries including the US, UK, France, Mexico and Indonesia, and India is resulting in many investment decisions being put on hold such as Tesla pausing their planned Mexico gigafactory until after the US election |

So what does this all mean for the automotive sector, in particular for manufacturing, logistics and supply chains?

Impact upon manufacturing

Delay/rollback of gigafactory and EV supply chain investments. We have seen that ACC has halted two gigafactories in Europe, in Germany SVOLT has halted plans for its Berlin gigafactory, and in the US Ford has paused work on its Michigan battery plant. Furthermore, to respond to fluctuating demand, battery production and supply chains need greater speed and agility to adjust.

Job cuts. Tesla announced it would lay off 10,000 staff, along with many other job cuts being announced by OEMs and tier suppliers.

Cost cutting. There will be an acceleration towards automation and smart manufacturing technologies to help reduce costs, including investing in more ‘gigacasting’ and ‘megacasting’.

Readjustment/shifting emphasis back to ICE & hybrid powertrains particular in Europe & North America – at least in the medium term as the more profitable vehicles to help finance the transition to (currently) loss-making EVs. For example, Ford has rolled back on EV investments and followed Toyota’s strategy to push hybrids more. And OEMs such as BMW are in a strong position as it has the flexibility to assemble (and switch to) EV, hybrid and ICE powertrains all on the same production line.

Vertical integration & localised supply chains. One of the main cost advantages that China has is its concentrated EV battery supply chain, so we expect to see more of this strategy to also help bring down costs.

Joint ventures. Legacy OEMs are only going to be able to compete if they embrace more joint ventures with Chinese EV companies. E.g. VW & Xpeng, Stellantis & Leapmotor, GM & SAIC, Ford & Changan etc. to achieve the platform sharing, accelerated development, and economies of scale to help bring down prices.

Conclusion

There’s no denying that the transition to EVs was always going to be tough. Compound this with the very real threat from drastically cheaper Chinese EVs and the stage is set for a very turbulent industry period. In fact, the CEO of Stellantis Carlos Tavares has frequently dubbed this era as “Darwinian” where only the fittest will survive, where a ‘Hunger Games’ style shakeout of legacy OEMs, and EV start-ups will inevitably fall by the wayside.

It will be for those automakers that executive the right strategy on price, technology & powertrain mix, and pace of EV investment that will ultimately decide the winners and losers.